33

Gas Input Rate Measurement (Natural Gas Only)

Natural Gas Minimum: 4.5" w.c. Maximum: 10.0" w.c.

Propane Gas Minimum: 11.0" w.c Maximum: 13.0" w.c.

INLET GAS SUPPLY PRESSURE

The actual gas input rate to the furnace must never be

greater than that specified on the unit rating plate. To

measure natural gas input using the gas meter, use the

following procedure.

1.

Turn OFF the gas supply to all other gas-burning

appliances except the furnace.

2. While the furnace is operating at high fire rate, time

and record one complete revolution of the gas meter

dial measuring the smallest quantity, usually the dial

that indicates 1/2 cu. ft. per revolution. You will use this

number to calculate the quantity of gas in cubic ft. if

the furnace would consume if it ran steadily for one

hour (3600 seconds).

3. If the 1/2 cu. ft. dial was used, multiply your number x 2.

EXAMPLE

: If it took 23 seconds to complete one

revolution of the 1/2 ft. dial (23 x 2 = 46).

This tells us that at this rate, it would take 46 seconds to

consume one cu. ft. of gas. 3600 / 46 = 78.

This tells us that in one hour, the furnace would consume

78 cu. ft. of gas.

The typical value range for 1 cu. ft. of natural gas is around

1000 BTU. Check with your gas utility, if possible. In this

example, the furnace is consuming 78,000 BTUH.

NOTE: The final manifold pressure cannot vary

by more than ± 0.3” w.c. for Natural and

+

0.5” for

LP from the specified setting. Consult your local

gas supplier if additional input rate adjustment is

required.

4. Turn ON gas to and relight all other appliances

turned off in step 1. Be certain that all appliances

are functioning properly and that all pilot burners are

operating.

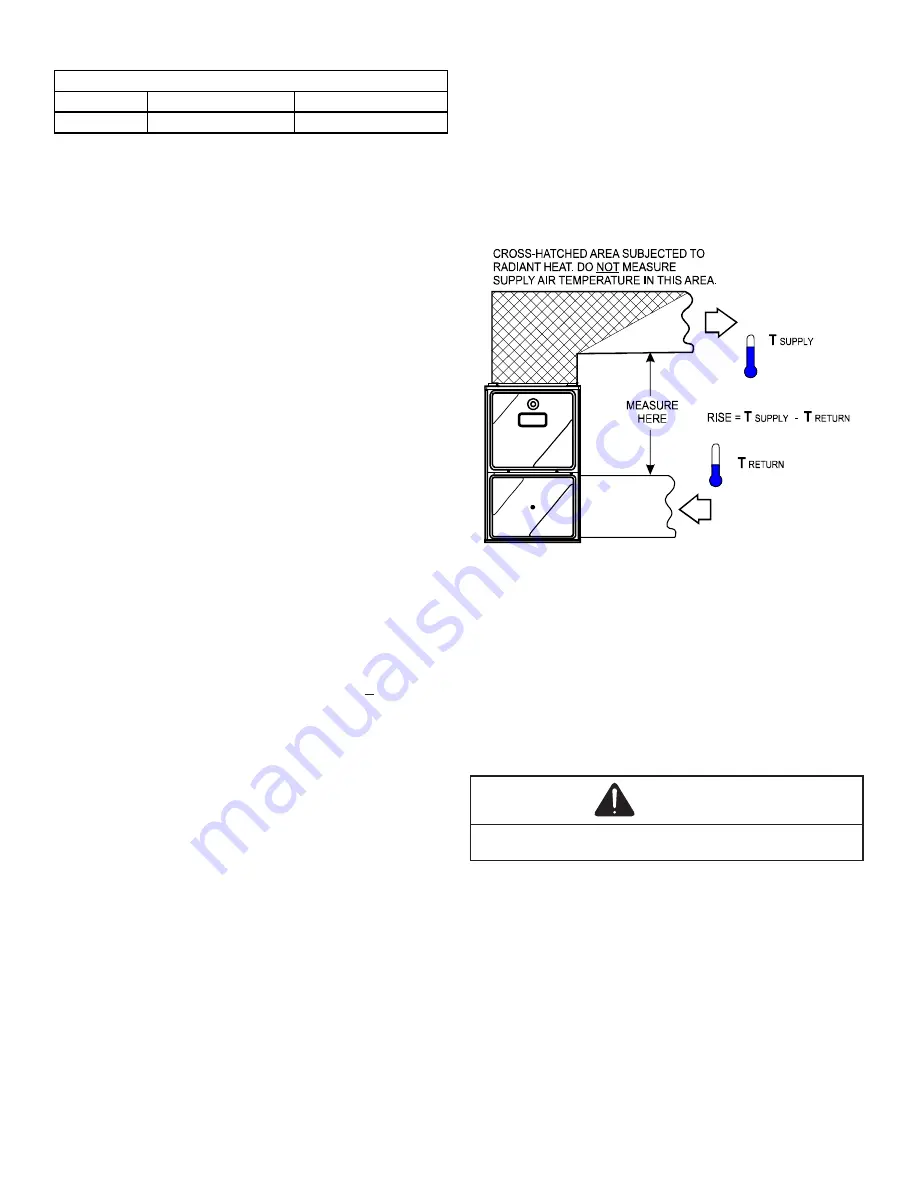

Temperature Rise

Temperature rise must be within the range specified on the

unit rating plate. An incorrect temperature rise may result

in condensing in or overheating of the heat exchanger.

An airflow and temperature rise table is provided in the

Specification Sheet applicable to your model. Determine

and adjust temperature rise as follows:

1. Operate furnace with burners firing for approximately

ten minutes. Ensure all registers are open and all

duct dampers are in their final (fully or partially open)

position.

2. Place thermometers in the return and supply ducts as

close to the furnace as possible. Thermometers must

not be influenced by radiant heat by being able to

“see” the heat exchanger.

3. Subtract the return air temperature from the supply

air temperature to determine the air temperature rise.

Allow adequate time for thermometer readings to

stabilize.

4. Adjust temperature rise by adjusting the circulator

blower speed. Increase blower speed to reduce

temperature rise. Decrease blower speed to increase

temperature rise. Refer to

Startup Procedure and

Adjustment - Circulator Blower Speeds

for speed

changing details.

SUPPLY

AIR

RETURN

AIR

Temperature Rise Measurement

Figure 45

Circulator Blower Speeds

This furnace is equipped with a multi-speed ECM motor.

The line voltage (115 VAC) power supply to the motor is

constant and not switched by the control board. Motor

operation is also dependent on a pulsing D.C. signal on

one of the four speed taps on the motor. The airflow tables

for heating and cooling speeds show the relationship

between airflow (CFM) and external static pressure for

each size furnace.

WARNING

To avoid personal injury or death due to electrical shock,

turn OFF power to the furnace before changing speed taps.

Circulator Blower Speed Facts

1. Motor speed Tap wiring must remain in factory

position on the control board and motor.

2. There are 4 speed Tap wires to the motor T1, T2, T3,

T4.

3. There are 5 speeds available, depending on DIP

switch settings and found in air flow table for each

size furnace.

4. Heating input (W1/ W2) always has priority over all

other thermostat input.

5. Cooling input (YLo/ Y) has priority over continuous fan

input.