13

CAUTION

To prevent improper and dangerous op-

eration due to wiring errors, label all wires

prior to disconnection when servicing

controls. Verify proper operation after

servicing.

Vll. Circulating Air and Filters

Airflow Conversion

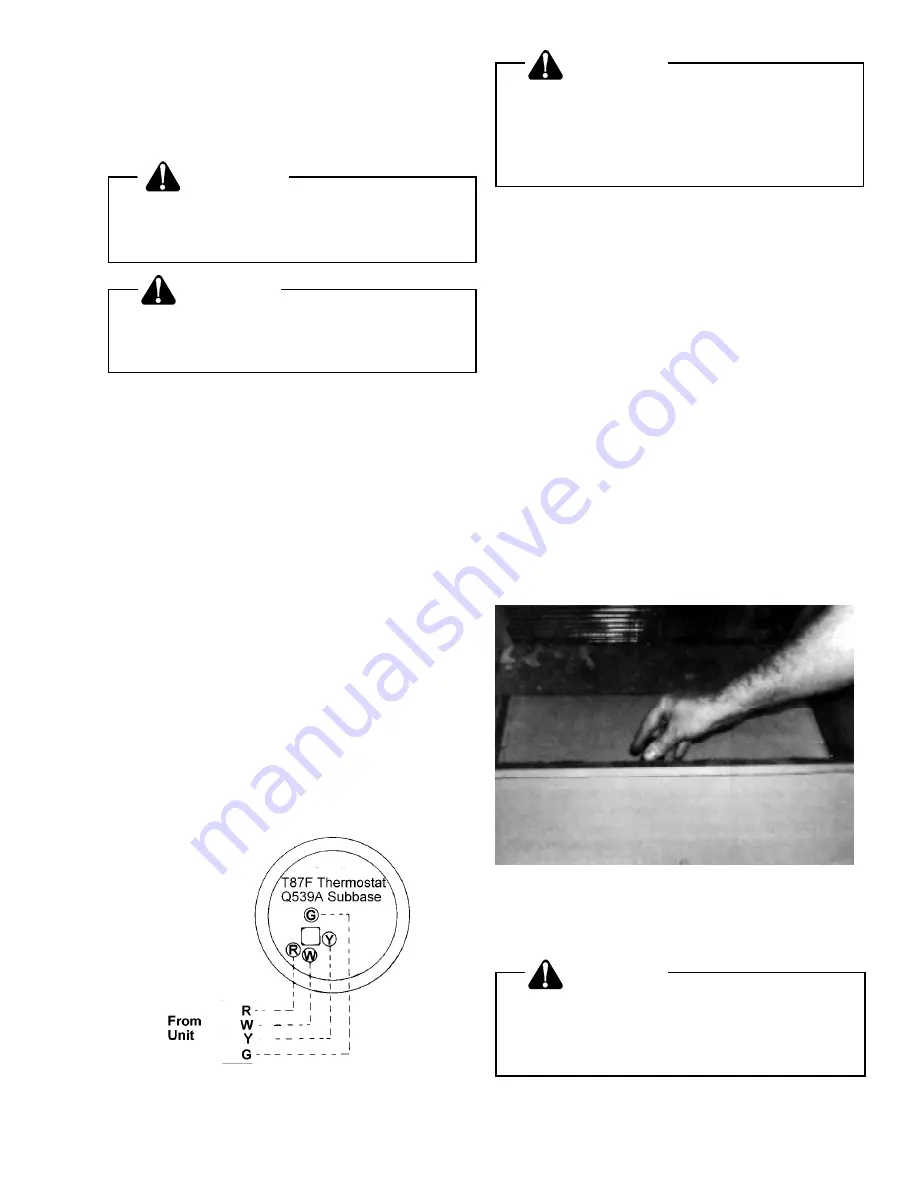

Units can easily be converted from horizontal to vertical

airflow delivery.

Units will ship from the factory ready for horizontal air-

flow. If conversion to vertical airflow is necessary, pro-

ceed as follows:

IMPORTANT: Be sure to save the flue hood assembly

(cardboard box) which is shipped in the return air com-

partment of the unit.

•

Remove panels from the bottom of the unit, saving

the mounting screws.

•

Remove insulation from outside of supply duct cover.

No insulation should face outside.

•

Relocate the panels on to the side of the unit, se-

curing with the screws removed earlier.

•

The unit will deliver the same amount of air whether

the airflow is vertical or horizontal. For details, see

the fan tables on Pages 2 - 5.

Figure 7

Airflow Conversion

Ductwork

CAUTION

To avoid possible fire, the cardboard

shipping support (located behind the

supply panel) must be removed before

operation.

IMPORTANT: Be sure to save the flue hood assembly

which is shipped in a cardboard box in the return air

compartment of the unit.

Please refer to the unit wiring diagram for electrical con-

nections. When installed, the unit must be electrically

grounded in accordance with local codes or in the ab-

sence of local codes with the latest edition of National

Electrical Code, ANSI/NFPA No. 70.

WARNING

To avoid death or personal injury due to

electrical shock, wiring to the unit must

be properly grounded.

CAUTION

To avoid personal injury or property dam-

age due to fire, use only copper conduc-

tors.

The best protection for the wiring is the smallest fuse or

breaker which will hold the equipment on the line during

normal operation without nuisance trips. Such a device

will provide maximum circuit protection. DO NOT EX-

CEED THE MAXIMUM OVERCURRENT DEVICE SIZE

SHOWN ON UNIT DATA PLATE.

Be sure line voltage connections are made through

weatherproof fittings. All exterior power supply and

ground wiring must be in approved weatherproof con-

duit. Low voltage wiring from the unit control panel to

the thermostat requires coded cable. For ground level

and rooftop wiring refer to Figure 8.

Unit Voltage

The unit transformer is factory connected for 230V op-

eration. If the unit is to operate on 208V, reconnect the

transformer primary lead and induced draft blower mo-

tor leads as shown on the unit wiring diagram.

Heat Anticipator Setting

The heat anticipator in the room thermostat must be

correctly adjusted to obtain the proper number of heat-

ing cycles per hour and to prevent the room tempera-

ture from overshooting the room thermostat setting. Heat

anticipator must be set at 0.8 amps.

Figure 6

Typical Thermostat and Unit 24 V Wiring

Hookup

Summary of Contents for PGB58B

Page 8: ...8 Figure 1 Required Clearances For All Installations...

Page 29: ...29 XVI Wiring Diagram PGC24 36...

Page 30: ...30 PGC 42...

Page 31: ...31 PGC 48...