22

Figure 18

Fan and Limit Control

CAUTION

This unit should not be used as a “con-

struction heater” during the finishing

phases of construction on a new struc-

ture. This type of use may result in pre-

mature failure of the unit due to extremely

low return air temperatures and exposure

to very dirty atmospheres.

To Turn Off Unit

1. Set the thermostat to lowest setting.

2. Turn off the electrical power supply to the furnace.

3. Remove the right hand door on the front of the fur-

nace by removing screws.

4. Turn the gas control valve knob to the OFF position.

Do not force. See Figure 16.

5. Close manual gas shutoff valve external to the fur-

nace.

6. Replace the door on the unit.

7. If cooling and/or air circulation will be desired, turn

ON the electrical power.

Cooling Startup

Compressor Protection Devices

The PGC and PGB includes components which are de-

signed to protect the compressor against abnormal op-

erating conditions. These include the short cycle pro-

tector, external compressor protector (PGC24-42, 60 and

PGB58 only), and high pressure cutout.

These controls reset automatically. Excessive cycling

of the controls should be investigated before continuing

operation.

(NOTE: The operation of the indoor blower will not be

affected by any of the above compressor protection de-

vices.)

WARNING

To avoid personal injury or death, always

disconnect electrical power before in-

specting or servicing the unit. All com-

pressor protection devices reset auto-

matically, energizing the contactor and

outdoor fan.

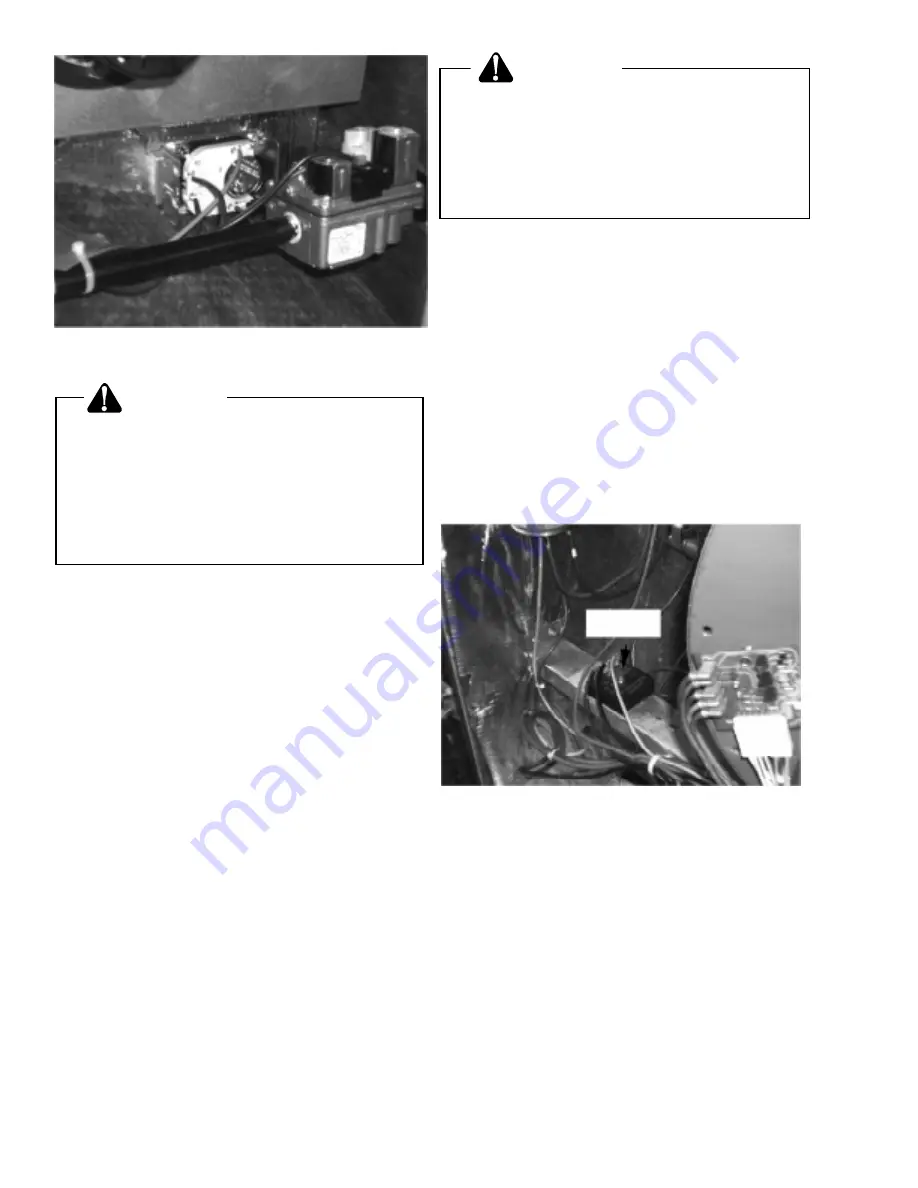

Short Cycle Protector (Figure 19)

The short cycle protector is located in the blower com-

partment. Each time the compressor shuts off for any

reason, the short cycle protector will open. It will take

about 3 to 4 minutes before the short cycle protector will

reset and allow compressor startup to occur.

All wiring connected to the short cycle protector is 24V.

If the compressor cycles on the short cycle protector

without cycling on any of the other compressor protec-

tion devices and before the call for cooling ends, com-

mon causes include:

•

Interruption of the line voltage power.

•

Improper thermostat installation, defective thermo-

stat wiring, or defective thermostat.

•

Rapid adjustments of the room thermostat.

Short Cycle

Protector

Figure 19

Short Cycle Protector Location

High Pressure Cutout (Figure 20)

An automatic reset high pressure control is located in

the compressor discharge line. (See Figure 20) This

control protects the unit from excessively high refriger-

ant pressure.

High pressures can result from:

•

Inoperative outdoor fan motor.

•

Outdoor coil restricted with debris.

•

Recirculation of hot condenser air.

•

Overcharge of refrigerant.

Summary of Contents for PGB58B

Page 8: ...8 Figure 1 Required Clearances For All Installations...

Page 29: ...29 XVI Wiring Diagram PGC24 36...

Page 30: ...30 PGC 42...

Page 31: ...31 PGC 48...