27

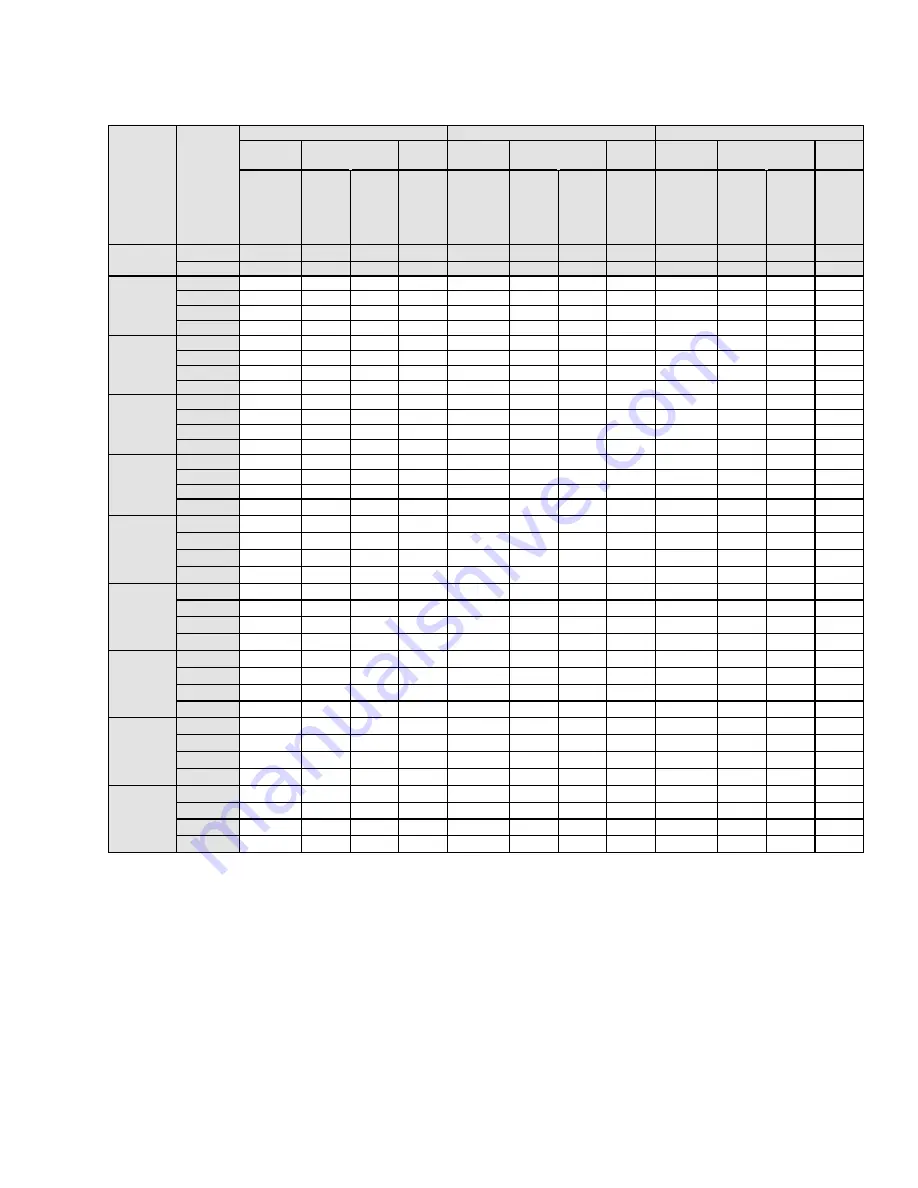

XV. Typical Cooling Performance Data

Outdoor

Indoor

PGC24

PGC30

PGC36

Air Tem p.

at

Air

Tem p.

Indoor

Air Tem p.

Pressure @ Unit

Gauge Fittings

Am ps

Indoor

Air Tem p.

Pressure @ Unit

Gauge Fittings

Am ps

Indoor

Air Tem p.

Pressure @ Unit

Gauge Fittings

Am ps

Condenser

Inlet

(Dry Bulb)

at Evap.

Inlet

(Wet Bulb)

Difference

Betw een

Coil Inlet

and Outlet

Low

Side

High

Side

Total to

Unit

Difference

Betw een

Coil Inlet

and Outlet

Low

Side

High

Side

Total to

Unit

Difference

Betw een

Coil Inlet

and Outlet

Low

Side

High

Side

Total to

Unit

A

B

C

D

E

B

C

D

E

B

C

D

E

° F.

° F.

° F.

PSIG

PSIG

Am ps

° F.

PSIG

PSIG

Am ps

° F.

PSIG

PSIG

Am ps

77

7

92

325

12.8

7

89

320

15.8

7

88

351

19.3

115

72

12

91

324

12.7

12

89

322

15.9

12

87

352

19.4

67

17

91

324

12.7

17

88

322

15.8

17

87

352

19.3

62

23

90

326

12.8

23

87

322

15.8

23

86

352

19.3

77

7

91

308

12.2

7

89

304

15.2

7

87

332

18.5

110

72

12

90

304

12.1

12

88

303

15.1

12

87

332

18.5

67

17

80

304

12.1

17

88

303

15.1

17

86

331

18.4

62

23

89

304

12.1

23

87

302

15.1

23

85

329

18.4

77

7

90

288

11.7

7

88

285

14.5

7

86

311

17.6

105

72

12

90

286

11.6

12

88

285

14.5

12

86

310

17.6

67

18

89

286

11.6

18

87

283

14.5

18

85

312

17.6

62

23

88

286

11.6

23

86

282

14.4

23

84

311

17.6

77

8

89

269

11.1

8

87

267

13.9

8

86

293

16.9

100

72

12

89

269

11.1

12

87

267

13.9

12

85

293

16.9

67

18

89

271

11.2

18

86

267

13.9

18

85

292

16.8

62

23

88

271

11.2

23

85

267

13.9

23

84

290

16.7

77

8

89

255

10.7

8

87

251

13.4

8

85

275

16.2

95

72

13

88

251

10.6

13

86

249

13.3

13

85

274

16.1

67

18

88

252

10.7

18

86

249

13.3

18

84

274

16.1

62

23

87

254

10.7

23

85

249

13.3

23

83

274

16.1

77

8

88

237

10.2

8

86

234

12.9

8

84

255

15.4

90

72

13

88

236

10.2

13

86

232

12.8

13

84

255

15.4

67

18

87

234

10.2

18

86

231

12.8

18

83

256

15.4

62

24

86

235

10.2

24

84

231

12.8

24

83

254

15.4

77

8

87

222

9.8

8

86

217

12.3

8

84

240

14.8

85

72

13

87

221

9.8

13

85

217

12.4

13

83

238

14.8

67

18

86

221

9.8

18

84

216

12.3

18

83

238

14.7

62

24

86

220

9.8

24

83

216

12.3

24

82

239

14.8

77

8

87

203

9.3

8

85

202

11.9

8

83

224

14.3

80

72

13

86

203

9.3

13

84

203

12.0

13

83

223

14.2

67

18

86

205

9.4

18

84

202

11.9

18

82

221

14.2

62

24

85

206

9.4

24

83

202

11.9

24

81

221

14.2

77

8

86

189

9.0

8

84

189

11.6

8

83

208

13.7

75

72

13

86

189

9.0

13

84

189

11.6

13

82

207

13.7

67

19

85

191

9.0

19

83

189

11.6

19

82

207

13.7

62

24

85

190

9.0

24

82

187

11.6

24

81

206

13.6

A Columns - All data based on indoor dry bulb of 80° F and rated air flow. As indoor dry bulb temperature increases, a slight increase will occur in indoor air temperature differential

between inlet and outlet. Low and high side pressures and power will not change.

B Columns - A properly operating unit should be within ±3° F of the typical (dry bulb) value shown.

C Columns - A properly operating unit should be within ±3 PSIG of the typical value shown.

D Columns - A properly operating unit should be within ±7 PSIG of the typical value shown.

E Columns - A properly operating unit should be within ±2 amps of the typical value shown.

Table 8A

Summary of Contents for PGB58B

Page 8: ...8 Figure 1 Required Clearances For All Installations...

Page 29: ...29 XVI Wiring Diagram PGC24 36...

Page 30: ...30 PGC 42...

Page 31: ...31 PGC 48...