3

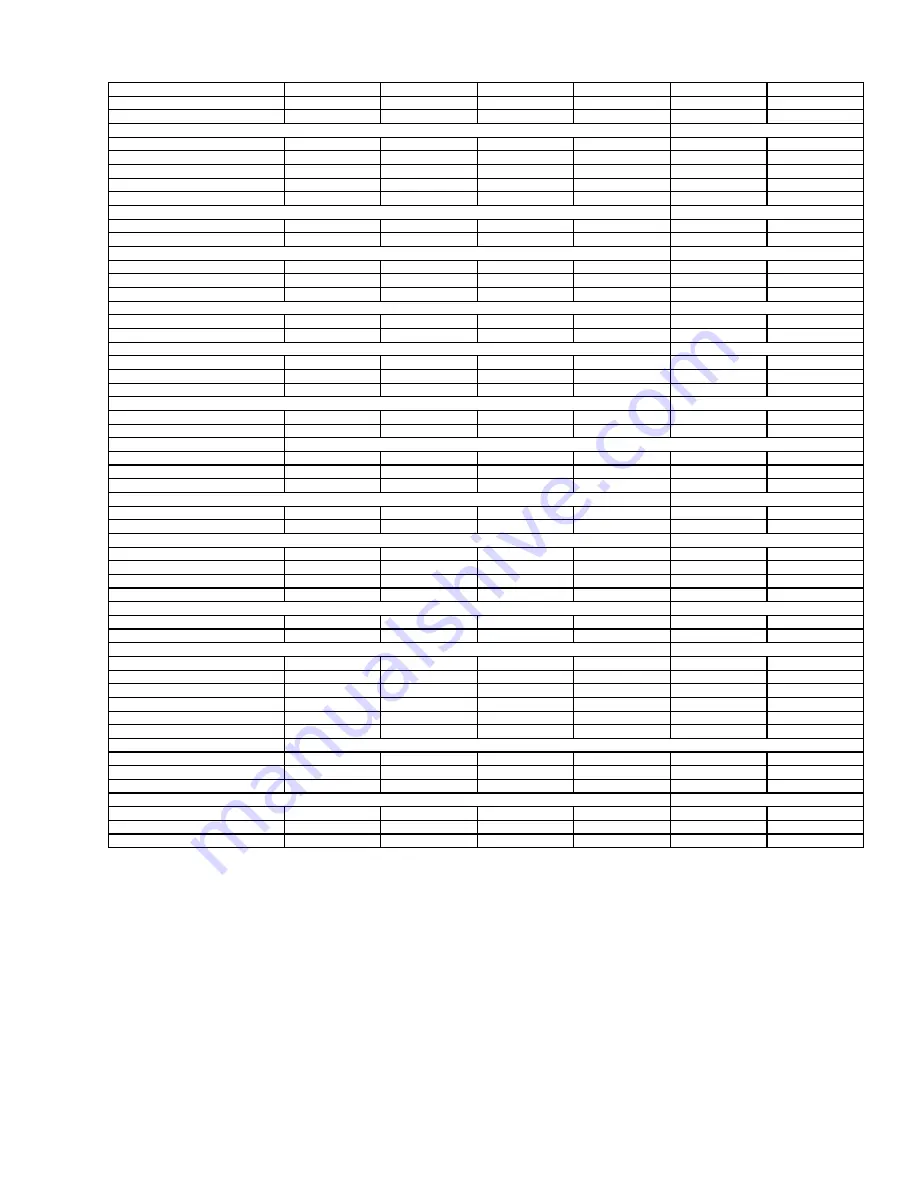

Table 1B

Gas Pack Specifications

1) United States Installation

2) Specification subject to change without notice. See sales specification sheets for certain BTUH capacities.

3) This PGC series complies with requirements embodied in the American National Standard ANSI-Z21.47 Central Furnaces.

4) Filters are not supplied with units, but filters must be installed in the unit filter rack or in the return air system.

** While the above data is presented as a guide, it is important to electrically connect the unit and properly size overcurrent protection and wires in accordance with the

National Electrical Code and all existing local codes.

Operating tolerance: Minus 5% on 208 VAC, Plus 10% on 208 VAC and 230 VAC, Minus 10% on 230 VAC

MODEL

PGC42B0902A

PGC42B1152A

PGC48B0902A

PGC48B1152A

PGC60B0902A

PGC60B1352A

Cooling Capacity Btuh

42,000

42,000

48,000

48,000

60,000

60,000

SEER

12.20

12.20

12.00

12.00

12.00

12.00

Heating

Input Btuh

90,000

115,000

90,000

115,000

90,000

135,000

Output Btuh

72,000

89,000

72,000

89,000

72,000

108,000

AFUE

81.4

79.9

81.4

79.9

81.4

80.5

Tem perature Rise °F

25-55

40-70

25-55

40-70

25-55

40-70

Num ber of Burners

4

5

4

5

5

6

Compressor

R.L. Amps

22

22

21.8

21.8

28.8

28.8

L.R. Amps

107

107

105

105

169

169

Condenser Coil

Face Area (sq. ft.)

17.2

17.2

17.2

17.2

17.2

17.2

Row s Deep

2

2

2

2

2

2

Fins/Inch

13

13

17

17

17

17

Condenser Fan

Diameter (in.)

24

24

24

24

24

24

CFM

3500

3500

3700

3700

4700

4700

Condenser Fan Motor

Horsepow er

1/4

1/4

1/2

1/2

1/3

1/3

R.L. Amps

1.5

1.5

1.5

1.5

2.5

2.5

L.R. Amps

3.4

3.4

3.6

3.6

6.4

6.4

Blow er Motor

Horsepow er

3/4

3/4

3/4

3/4

1

1

R.L. Amps

5

5

5

5

7

7

L.R. Amps

Blow er Wheel Dia. x Width (in.)

10x10

10x10

10x10

10x10

11x8

11x8

Rated CFM, Cooling

1450

1450

1700

1700

1750

1750

Max. External

0.8" w c

0.8" w c

0.8" w c

0.8" w c

0.8" w c

0.8" w c

Combustion Blow er

Diameter x Width (in.)

4 x 1.25

4 x 1.25

4 x 1.25

4 x 1.25

4 x 1.25

4 x 1.25

No.

1

1

1

1

1

1

Condenser Blow er Motor

H.P.

0.03125

0.03125

0.03125

0.03125

0.03125

0.03125

F.L. Am ps.

0.5

0.5

0.5

0.5

0.5

0.5

Press. Sw itch Setting (" W.C.)

-0.65

-0.65

-0.65

-0.65

-0.65

-0.65

Ignition - Lockout Timing (sec.)

4

4

4

4

4

4

Flame Sense Current (m icroam ps)

Minim um

1

1

1

1

1

1

Maximum

6

6

6

6

6

6

Evaporator Coil

Face Area (Sq. Ft.)

5.7

5.7

5.7

5.7

5.7

5.7

Row s Deep

2

2

3

3

3

3

Fins/Inch

15

15

15

15

15

15

External Filter Size (Sq. Ft.)

5.3

5.3

5.3

5.3

5.3

5.3

Drain Line Size (in.)

3/4

3/4

3/4

3/4

3/4

3/4

Expansion Device (Cooling)

Capillary

Capillary

TEV

TEV

TEV

TEV

Refrigerant Charge

Refer to unit name plate for correct charge

Pow er Supply**

208/230-60-1

208/230-60-1

208/230-60-1

208/230-60-1

208/230-60-1

208/230-60-1

Min. Circuit Ampacity

34

34

39.5

39.5

49.7

49.7

Max. Overcurrent Device

50

50

50

50

70

70

Electrical Entrance Size

Pow er Supply

1 1/4", 1 1/2", 2"

1 1/4", 1 1/2", 2"

1 1/4", 1 1/2", 2"

1 1/4", 1 1/2", 2"

1 1/4", 1 1/2", 2"

1 1/4", 1 1/2", 2"

Low Voltage

7/8"

7/8"

7/8"

7/8"

7/8"

7/8"

Approx. Shipping Weight (lbs)

521

527

526

526

531

531

Protected by redundant electronic control circuts

Summary of Contents for PGB58B

Page 8: ...8 Figure 1 Required Clearances For All Installations...

Page 29: ...29 XVI Wiring Diagram PGC24 36...

Page 30: ...30 PGC 42...

Page 31: ...31 PGC 48...