5

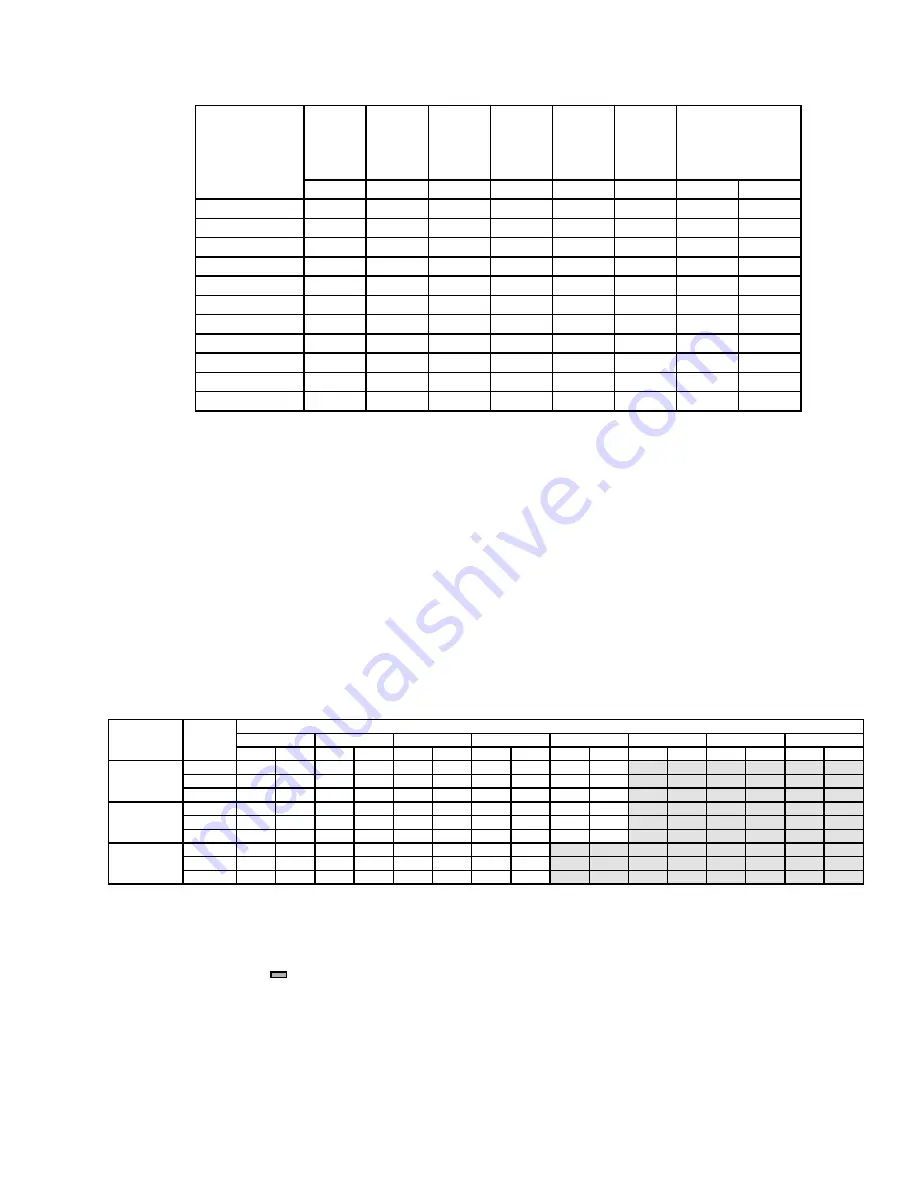

1. Installation is to be adjusted to obtain temperature rise within the range specified on the rating plate.

2. The temperature rise is for units installed at 0-2000 feet. At higher altitudes, a properly derated unit will have

approximately the same temperature rise and CFM.

3. The chart is applicable for both vertical and horizontal airflow.

4. All speed tap settings are factory selected according to unit size.

5. Data shown without filters. Consult filter manufacturer for pressure drop to be added.

6. Motor is constant CFM for external static pressures 0.1" to 0.8" W.C.

7. Maximum External Pressure Limits

PGC 24-42 0.8" W.C.

PGC46 & 60 1.0 W.C.

Table 2A

PGC Temperature Rise Table

NOTE:

1. All airflow is dry coil.

2. Installation is to be adjusted to obtain temperatures rise within the range specified on the rating plate.

3. The above chart is for information only. For satisfactory operation, external static pressure should not exceed value shown on the rating

plate. The shaded area (

) indicates in excess of maximum external static pressure allowable when heating.

4. This chart is for units installed at 0-2000 feet. At higher altitudes, a properly derated unit will have approximately the same temperature

rise at a particular CFM, while ESP at that CFM will be lower.

5. Cooling operation may require a different fan speed than heating operation. For details, see Wiring Diagrams.

6. Above chart is applicable for both vertical and horizontal airflow.

Table 2B

PGB CFM& Temperature Rise vs. External Static Pressure Table

External Static Pressure, Inches Water Column

Motor

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Model

Speed

CFM

RISE

CFM

RISE

CFM

RISE

CFM

RISE

CFM

RISE

CFM

RISE

CFM

RISE

CFM

RISE

Hi

2160

31

2120

31

2080

32

2030

33

1990

34

1945

34

1900

35

1835

36

PGB58B0902C

Med

1750

38

1750

39

1700

39

1680

40

1680

40

1615

41

1575

42

1490

45

Lo

1490

45

1480

45

1470

45

1450

46

1440

46

1415

47

1360

49

1280

52

Hi

2160

---

2120

---

2080

41

2030

42

1990

43

1945

44

1900

45

1835

46

PGB58B1152C

Med

1750

49

1750

49

1700

50

1680

51

1650

52

1615

53

1575

54

1470

57

Lo

1490

57

1480

58

1470

58

1460

58

1440

59

1415

60

1360

63

1280

67

Hi

2160

46

2120

47

2080

48

2030

49

1990

50

1945

51

1900

53

1835

54

PGB58B1352C

Med

1750

57

1750

58

1700

59

1680

60

1650

61

1615

62

1575

63

1490

67

Lo

1490

67

1480

68

1470

68

1460

68

1440

69

1415

---

1360

---

1280

---

Model

Nominal

Cooling

Nominal

Nominal

Heating

Nominal Nominal

Temp.

Speed

Capacity

(MBh)

Cooling

CFM

Capacity

(Input)

Heating

CFM

Fan Only Rise (°F)

Taps

(Y+G)

(W1)

(G)

Cool

Heat

PGC24B0452A

24000

850

45000

930

570

35

A

A

PGC24B0702A

24000

850

70000

1140

570

45

A

B

PGC30B0702A

30000

1100

70000

1140

570

45

B

B

PGC36BO702A

36000

1300

70000

1140

570

45

C

B

PGC36B0902A

36000

1300

90000

1350

570

55

C

C

PGC42B0902A

42000

1450

90000

1650

815

40

A

A

PGC42B1152A

42000

1450

115000

1530

815

55

A

B

PGC48B0902A

48000

1700

90000

1650

815

40

B

A

PGC48B1152A

48000

1700

115000

1530

815

55

B

B

PGC60B0902A

60000

1750

90000

1650

815

40

A

A

PGC60B1352A

60000

1750

135000

1900

815

55

A

B

Summary of Contents for PGB58B

Page 8: ...8 Figure 1 Required Clearances For All Installations...

Page 29: ...29 XVI Wiring Diagram PGC24 36...

Page 30: ...30 PGC 42...

Page 31: ...31 PGC 48...