17

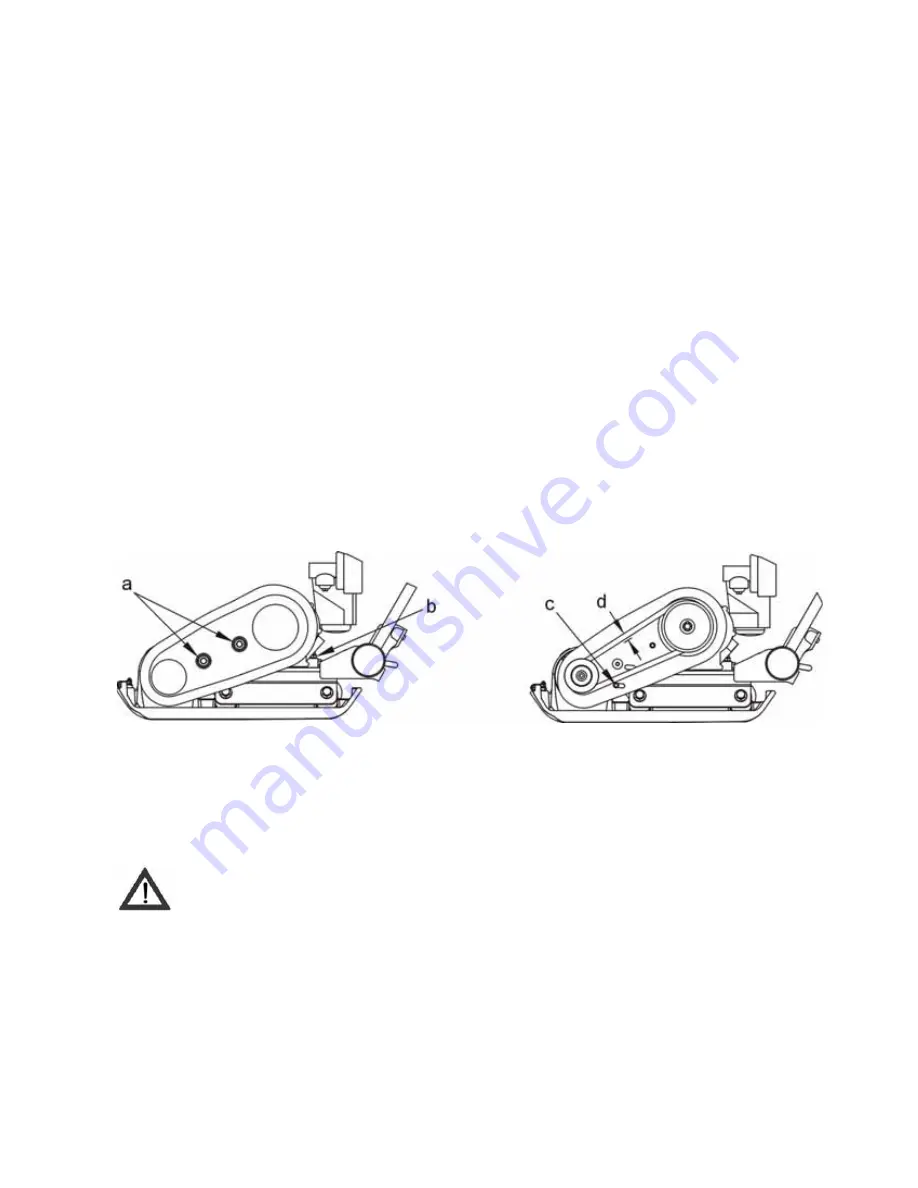

To adjust belt:

5.3.1 Loosen the two screws (

a

) on the beltguard, then remove the beltguard, keeping the

screw assemblies captured on the beltguard.

5.3.2 Loosen the four nuts (

b

) which hold the engine to the console, and the screw (

c

)

which holds the beltguard back to the console.

5.3.3 Slide the engine backward (towards the handle) to tighten the belt, forward to

loosen the belt.

5.3.4 Adjust the belt so that it deflects 10–13 mm (

d

) when pressed midway between the

belt pulleys.

5.3.5 Make sure that the clutch pulley (

f

) and the exciter pulley (

e

) are in alignment.

Place a straight edge against the exciter pulley (

e

) and move the engine so that the

two pulleys are parallel.

5.3.6 Torque all nuts and screws to 20.5 Nm as you reassemble the machine.

Graphic 4

5.4 Spark Plug

See Graphic 5

Clean or replace spark plug as needed to ensure proper operation. Refer to the engine

Owner’s Manual.

WARNING:

The muffler becomes very hot during operation and remains hot for

awhile after stopping the engine. Do not touch the muffler while it is hot.

Note:

Refer to the Technical Data for the recommended spark plug type and the

electrode gap setting.

5.4.1 Remove spark plug and inspect it.

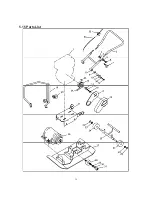

Summary of Contents for PDZ1240

Page 8: ...7 2 5 Label Locations Graphic 1...

Page 27: ...26 5 15 Parts List...