Construction and function of the sprayer boom

6.14

Nozzles

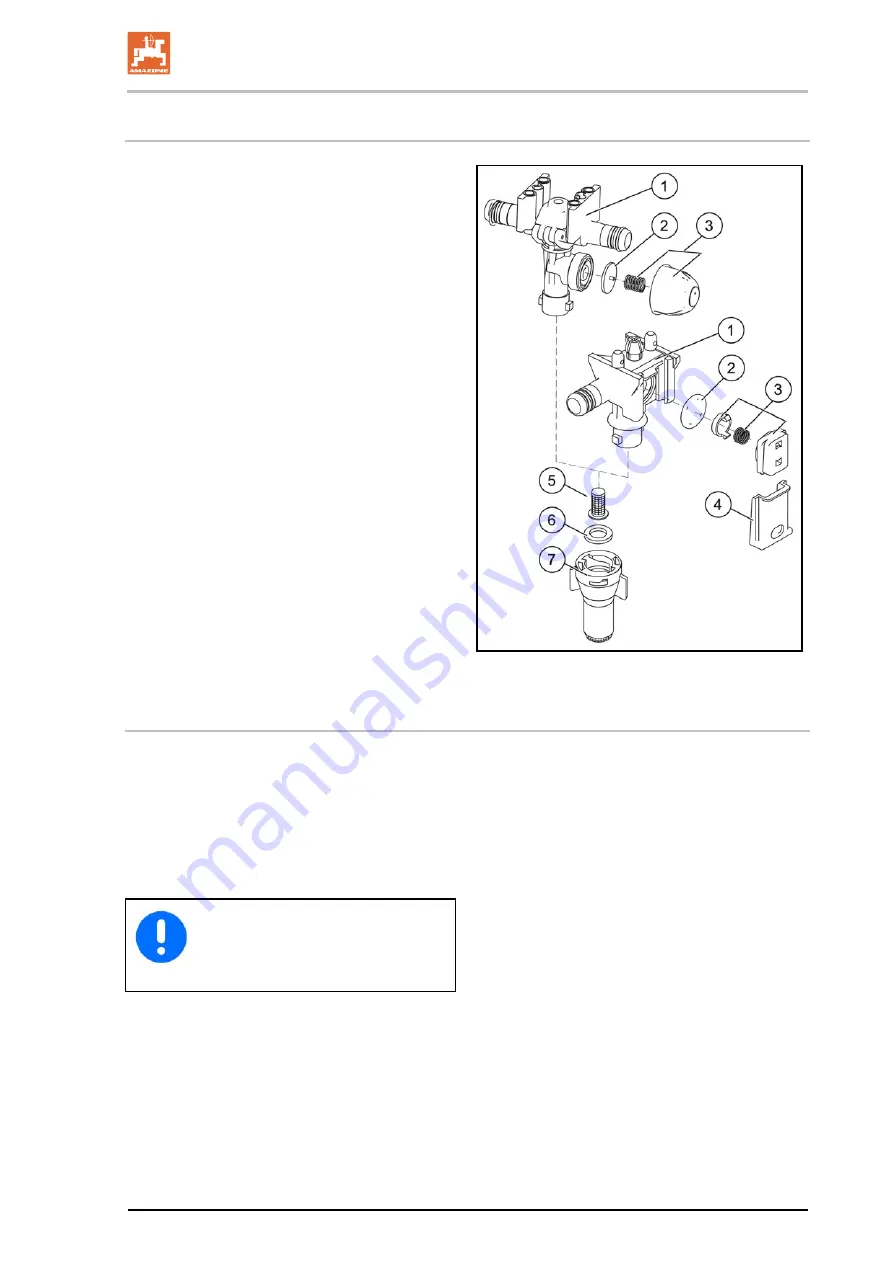

(1) Nozzle body with bayonet connection

ο

Spring element version with shutter

ο

Spring element version, bolted

(2) Diaphragm. If the pressure in the spray line

falls below approx. 0.5 bar, the spring ele-

ment (3) presses the diaphragm onto the

diaphragm seat (4) in the nozzle body. This

ensures that when the sprayer boom is

switched off, the nozzles are deactivated

without subsequent dripping.

(3) Spring element.

(4) Shutter; holds the entire diaphragm valve in

the nozzle body

(5) Nozzle filter; fitted as standard on machines

with 50 mesh/inch, is inserted from below

into the nozzle body.

(6) Rubber seal

(7) Nozzle with bayonet cap

Fig. 94

6.14.1

Multiple nozzles

It is advantageous to use multiple nozzle heads

when using different nozzle types.

Turning the multiple nozzle head counterclock-

wise brings a different nozzle into play.

The multiple nozzle head is switched off in the

intermediate positions. This provides the possi-

bility of reducing the working width of the boom.

Flush the spray lines before twisting

the multiple nozzle head to another

nozzle type.

BAG0021.14 05.19

117

Summary of Contents for UG 2200 Special

Page 237: ...Liquid circuit 13 1 UG Special BAG0021 14 05 19 237 ...

Page 238: ...Liquid circuit 13 2 UG Super 238 BAG0021 14 05 19 ...

Page 242: ...Spray table Fig 182 242 BAG0021 14 05 19 ...

Page 251: ...Spray table BAG0021 14 05 19 251 ...

Page 252: ......