Cleaning, maintenance and repair

21.

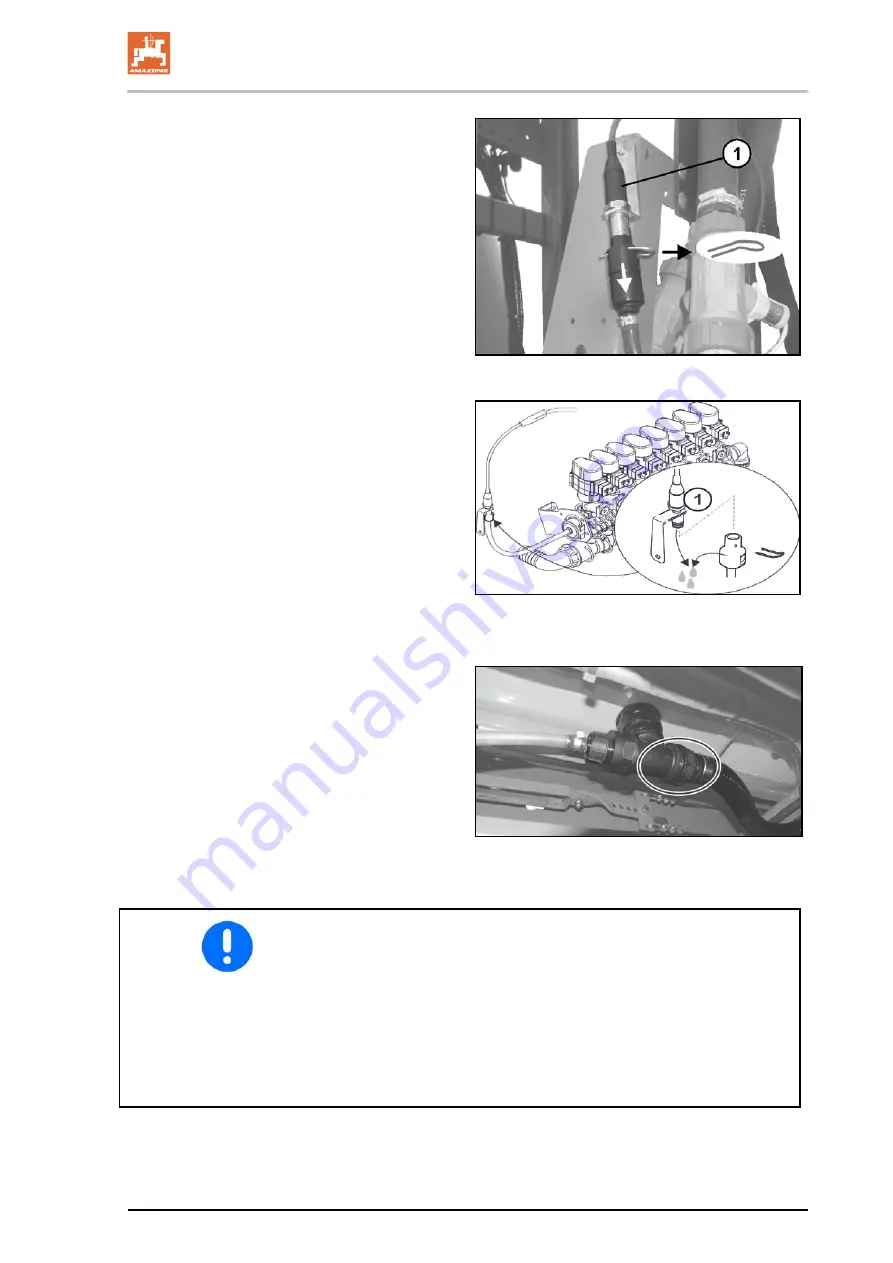

Super-S boom:

drain the pressure sensor

(Fig. 145/1) of the boom fitting with the

boom lowered by removing the hose from

the pressure sensor..

Fig. 146

22.

Super-L1 boom:

drain the pressure sensor

of the boom fitting with the boom lowered

by removing the hose from the pressure

sensor.

Fig. 147

23. Drain the flushing water tank, by removing

the hose from the des flushing water tank.

Fig. 148

Before starting up again:

•

Install all of the dismantled parts.

•

Close the suction port drainage tap.

•

At temperatures below freezing, hand crank the piston dia-

phragm pumps before starting to prevent residual ice from dam-

aging the piston and piston diaphragm.

•

Store the pressure gauge and any other electronic accessories

in a place where they are safe from frost!

BAG0021.14 05.19

197

Summary of Contents for UG 2200 Special

Page 237: ...Liquid circuit 13 1 UG Special BAG0021 14 05 19 237 ...

Page 238: ...Liquid circuit 13 2 UG Super 238 BAG0021 14 05 19 ...

Page 242: ...Spray table Fig 182 242 BAG0021 14 05 19 ...

Page 251: ...Spray table BAG0021 14 05 19 251 ...

Page 252: ......