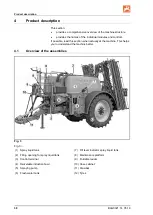

Product description

4.6

Regular device inspections

The implement underlies the European Union

universally applicable regular device inspections

(Crop Protection Directive 2009/128/EC and EN

ISO 16122)).

Have the device inspected at regular intervals by

a recognised and certified inspection workshop.

The date for performing the next device inspec-

tion is written on the inspection plate on the im-

plement.

Fig. 15: German inspection plate

Fig. 14

4.7

Consequences of using certain crop protection agents

We would like to draw attention to the fact that extended exposure (20

hours) to crop protection agents with which we are familiar, e.g. Las-

so, Betanal and Tramat, Stomp, Iloxan, Mudecan, Elancolan and Ter-

idox, can cause damage to the pump diaphragms, hoses, spray lines

and tanks. The examples given are in no way intended to represent a

comprehensive list.

In particular, we warn against unauthorised mixtures of two or more

different crop protection agents.

Substances which have a tendency to stick together or set must not

be applied.

When using such aggressive crop protection agents, it is recom-

mended that the spray liquid be applied immediately after preparation

and then that the sprayer be thoroughly cleaned with water.

Viton membranes are available as replacements for pumps. These

are resistant to solvent-containing crop protection agents. However

their service life is reduced by use at low temperatures (e.g. AUS in

frosty conditions).

The materials and components used in the construction of AMAZONE

field sprayers are safe for liquid fertiliser.

44

BAG0021.14 05.19

Summary of Contents for UG 2200 Special

Page 237: ...Liquid circuit 13 1 UG Special BAG0021 14 05 19 237 ...

Page 238: ...Liquid circuit 13 2 UG Super 238 BAG0021 14 05 19 ...

Page 242: ...Spray table Fig 182 242 BAG0021 14 05 19 ...

Page 251: ...Spray table BAG0021 14 05 19 251 ...

Page 252: ......