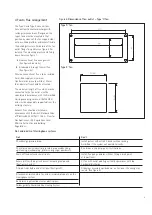

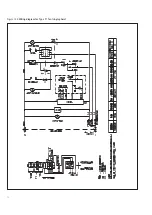

Manifold pipe size (mm)

Maximum distance between supports (m)

100

2.4

150

3.0

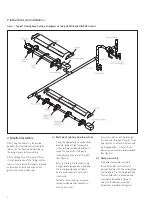

3.3 Manifold suspension

The manifold should be supported

by chain, stainless steel flexible wire,

or other flexible means from the roof

structure to allow movement caused

by thermal expansion. For maximum

support centres see figure 5.

Flexible couplers (supplied by

Ambi-Rad) must be inserted within

the manifold system to allow linear

expansion to take place and prevent

stress and strain on the system.

Note

The manifold must be supported

either side of the flexible coupler.

Where the HB heaters are to be

inclined/wall mounted, the manifold

must be installed at the same height as

the centre of the emitter tube. For

typical wall mounting bracket

arrangement see AR installation

manual (GB/ARE(E)079/0501).

Figure 5

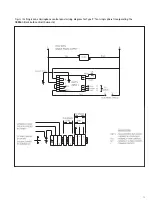

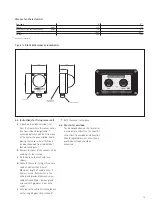

3.4 Condensate trap

A condensate trap assembly must be

provided at the end of the manifold

system before the hot gas vacuum fan.

(See figure 8a)

The minimum depth of the condensate

collecting chamber shall be 305mm

(12in) and the minimum depth of the

condensate drain pipe ‘U’ trap shall

be 457mm (18in) deep.

The end cap of the collecting chamber

to be fitted with a flush flanged tank

connector. Any protrusion to be

removed leaving the inside flush

with end cap (see figure 9). The end cap

to be sealed with silicon jointing

compound and pop riveted in position.

All condensate drains from the flue

collecting chamber to the disposal point

shall be corrosion-resistant material of not

less than 22mm internal diameter. Copper or

copper based alloy shall not be used for

condensation drains. See reference

BS 6896:1991. Condensate drain pipes must

be protected against the effects of freezing.

5