0501UCA

14/25

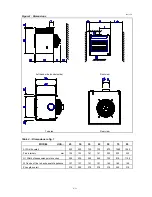

Figure 11.

BURNER ASSEMBLY REMOVAL

9.8

Burner tray removal :

Refer to figs. 11, 15 & 16

1 Disconnect

gas

supply

at the unions below the

inlet gas service tap and adjoining the gas

control valve.

2

Disconnect the wires leading to the gas valve

at the valve terminal end.

3

Disconnect wires leading to the thermal

overheat cut off device terminals.

4

Unscrew qty. 2 burner tray fixing screws.

5

Withdraw the burner assembly by pulling from

its runners until it is released.

6

To reassemble reverse procedure 1 thru. 5.

9.9 Note :

Appliances for use on propane or butane gas

have an aeration shutter fitted to the burner

inlet air venturi (see fig. 17). This device may

also be fitted to natural gas appliances which

have been converted. The shutter is set and

sealed by a multi- functional sealing plate

marked LPG + NG. Ensure it is correctly reset

after any burner service work is carried out.

9.10

To renew or service the gas valves :

Remove burner rack assembly as described

9.7 above. To dismantle valve from manifold,

take care when using spanners not to damage

valve bodies which are constructed from soft

die cast aluminium. It is necessary to remove

the burner manifold from the burner ribbon tray

assembly to unscrew the gas valve.

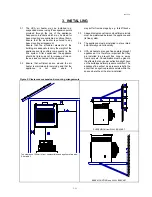

Figure 12.

DRAUGHT DIVERTER REMOVAL

1.Draught diverter securing screws left and right hand side.

9.11 Electrical:

Check all visible wiring for damage, check

terminal security.

When removing for service or renewal any

electrical component follow a logical sequence

to ensure that replacement will be correct. Mark

wiring to ensure before disconnection to ensure

that circuits are re-connected correctly.

9.12

Flue system:

Check that flue is in good condition adequately

supported and that the flue and supports are

free from corrosion and that the flue is

unobstructed. Test for a positive up-draught

when re-commissioning the appliance by using

smoke introduced into the draught hood slot at

the front of the air heater.

On flue systems fitted with an Euroventer refer

to the separate instructions supplied with the

Euroventer.

9.13

Fan assembly:

When it is necessary to remove the fan blade

from the motor it should be noted that the

securing screw is fitted using a thread sealing

compound. local heat may be required to soften

the compound so that the screw may be

loosened.