0501UCA

6/25

UCA

Model

Heat Input

kW

Room

Volume m³

25

30.28

142

30

34.94

165

35

43.26

203

45

52.00

245

55

64.67

304

75

88.96

418

95

118.70

558

UCA

Model

Heat

input kW

Low

level

cm²

25

30.28

140

30

34.94

160

35

43.26

200

≤

60 kW

45

52.00

240

55

64.70

290

75

88.95

340

≥

60 kW

95

118.70

410

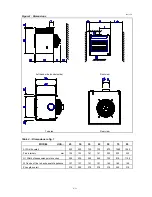

Table 3 : Dimensions re fig. 2

UCA

25

30

35

45

55

75

95

L minimum

550

620

750

900

1100

1400

L1 Opposite side

150

300

4. AIR SUPPLY for COMBUSTION & VENTILATION

4.1

It is essential that sufficient fresh air is provided

for combustion and room ventilation. Most

traditional building constructions have a natural

air change rate of at least 0.5/h. Where it is

known that the air change rate is at least 0.5/h

and where the volume of the heated space is

greater than 4.7m³ per kW of total rated heat

input, additional ventilation is not required.

4.2

Table 4.

Building volume limits for UCA air Heaters

based upon 4.7m

3

per kW of rated heat

input for one air heater only.

If the minima volumes stated above exist

together with appropriate similar allowances for

other combustion plant that may be installed in

the same space or zone, then additional

ventilation is not required.

4.3

Where it is known that the air change rate is less

than 0.5/h or where the building volume is less

than 4.7m³ per kW of heat input, ventilation

grilles must be provided at low level i.e. below

the level of the appliance flue connection. In

cases where doubt exists over the air change

rate ventilation should be provided.

For air heaters of heat input less than

60 kW the total minimum free area shall not be

less than 4.5 cm² per kW of total rated heat

input as table 5 below.

For our heaters of heat input 60 kW or more the

total minimum free area shall not be less than

270 cm² plus 2.25 cm² per kW in excess of the

60 kW rated heat input.

4.4

Table 5. Air Supply Requirement for

Combustion & Ventilation.

Note :

Ventilation grilles must be installed so

that air is drawn directly from outdoors. In the

event that communication from the space where

the heater is installed to outdoors is via another

room then the route to outdoors must be ducted

through the communication area.

The grille velocity for all air supply must not

exceed 2.0 m/s. Grilles should be sited where

they cannot easily be blocked or flooded.

Notices should be provided advising about the

need to keep air supply grilles unobstructed.

4.5 Where

mechanical

ventilation is used it shall be

by mechanical inlet with either mechanical or

natural extraction. Automatic means of control

such as interlocks must be provided. The

function of other ventilation plant in the zone

must be taken into account. At no time should it

be possible to create a negative pressure in the

zone as this will lead to a hazardous situation

whereby the air heater flue will act as a pressure

relief.

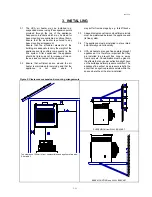

4.6

Normally UCA air heaters are installed within the

room or space to be heated. If it is necessary to

install the air heater in a separate room and

blow the air into an adjoining room, then a short

duct not exceeding 1,0 metre may be used to

connect the appliance to the air discharge louvre

as shown in figure 3.