4211-189 08-09-11

page 5

A220FP Fragrance Injector Pump

Installation and Operating Instructions

2 GANG ROUGH-IN BOX

DIAGRAM 14

DIAGRAM 13

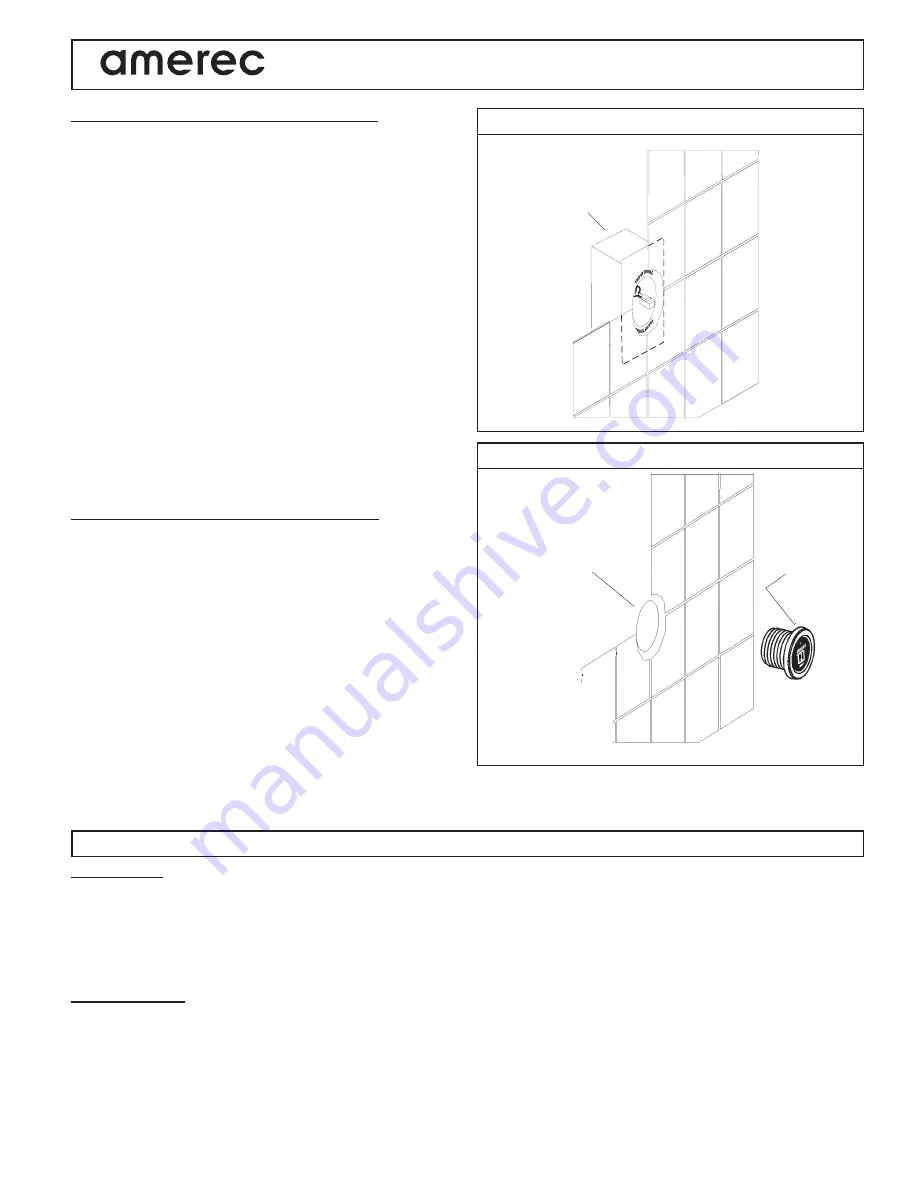

APPLY SEALANT

(100% SILICONE CAULK)

TILE UP TO

45 mm DIAMETER HOLE

IN FINISHED WALL

(OPTIONAL NUT IF BACK OF

WALL IS ACCESSABLE)

DIAGRAM 13

DIAGRAM 12

Single Position

Rough-in Box

(optional)

Apply Sealant

(100% Silicone

Caulk)

Tile up to 1-3/4"

diameter hole in

finished wall

Install the Fragrance Controller (continued)

while pressing the terminal block tabs with a small tip

screw driver. Release the tabs to secure the wires.

• Place a strain relief (provided, not shown) around the

cable Close to the controller's end and squeeze it closed

with pliers while pushing it into the hole to secure the

cable.

• Plug the adapter into a convenient wall outlet.

• Secure the cord to the wall as needed to prevent stress or

other risks of damage.

• Run the pump's power cord to the controller and through

the second hole in the controller's end. Connect the cord

to the terminals block's PUMP positions and install a

strain relief and secure the cord in the same manner used

for the power cable.

•Run the thermal switch's cable to the controller and

through the third hole in the controller's end. Connect the

stripped wires ends to the terminals block's

SWITCH

positions, install a strain relief and secure the cable in

the same manner used for the power cable.

Install the On/Off Switch (Diagrams 12 & 13)

The low voltage control can be mounted directly to a

finished wall either inside or outside the steam room.

• Rough-in the control cable (this cable has an plug on

each end similar to a telephone's).

• Using a 1-3/4" hole saw, drill a hole in the finished wall

where the control is to be mounted.

• Locate the control cable, pull it out through the 1-3/4" hole

and plug the cable into the connector in the back of the

control housing.

• Run a bead of 100% silicone caulk around the perimeter

on the back of the control housing. Insert the control into

the 1-3/4" hole.

• Using the methods previously listed, connect the other

end of the control cable to the Fragrance Controller's

CONTROL

jack and secure the cable..

OPERATING INSTRUCTIONS

Initial Set-Up

• Make sure the essence bottle is filled with fragrance oil. * Note:

Never let the essence container or tubing run dry.

An extended lack of oil could cause damage to the tubing or pump

.

• Make sure the power adapter is connected to 120VAC then turn the pump on by pressing the pump's On/Off/Mom

switch in to the center ON position. Note: the pump will not run until the Fragrance Controller is turned on by the

On/Off switch and steam is enterring the room.

Basic Operation

To turn on the injector system, simply press the switch on the On/Off switch. Once pressed:

• The switch's LED will light, indicating that the injector system is running.

• The pump will run for a short time every 2 minutes, if the steam is heating the room.

• After about 15 minutes, the system will automatically turn off and the switchs LED will turn off.

Note: Fragrance will not be injected until the room is over 100° F.

Summary of Contents for A220FP

Page 1: ......