9

b. Carefully tip extinguisher over until it rests on both wheels and handle. (In this

position much of the agent will remain in the cylinder).

c. Open nozzle valve slowly to clear hose of any remaining pressure and chemical (be

prepared for a recoil and discharge of agent).

d.

Insure that all pressure has escaped before further disassembly

.

e. Stand extinguisher upright after complete depressurization.

2.

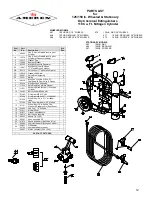

Complete items 1-6 of Maintenance Procedures. Carefully remove the fill cap. Detach

discharge hose from the agent cylinder and the nozzle assembly from the hose. Blow out

any chemical remaining in the hose. While performing this procedure, all parts and seals

should be cleaned, inspected and replaced where necessary.

3.

Remove shutoff nozzle assembly from discharge hose and clean thoroughly. Check to

make sure that the valve is closed when the lever is in the forward position (toward the

nozzle tip).

4.

Detach hose from nitrogen cylinder, install the shipping cap, unscrew the wing nuts and

remove the nitrogen cylinder from the extinguisher.

5.

Remove the 50 ft. discharge hose from the storage rack and disconnect the hose from the

agent cylinder fitting. Blow out any dry chemical agent remaining in the hose. clean hose –

remove and discard the clear hose gasket from the female coupling.

6.

Remove remainder of ruptured moisture seal from the agent cylinder fitting. Replace with

new Moisture Seal Assembly.

Carefully follow the installation instructions contained in

the Moisture Seal Assembly package, including the installation of a new clear hose

gasket in the female hose coupling

.

7.

Remove the agent cylinder fill cap and gasket. Clean fill cap threads and vent port, lubricate

the cap gasket and set parts aside. Check the condition and type of any remaining chemical

(replace any dry chemical that is contaminated or caked). Fill extinguisher with the type and

amount of dry chemical shown on the extinguisher label – verify gross weight. Clean agent

cylinder collar threads. Install the fill cap and tighten securely.

WARNING:

DO NOT OVERFILL THE EXTINGUISHER. THIS COULD CAUSE A

MALFUNCTION. DO NOT MIX TYPES OF AGENTS – THIS CAN CAUSE A

DANGEROUS PRESSURE BUILD UP AND REDUCE EXTINGUISHER

EFFECTIVENESS.

8.

Install the proper nitrogen cylinder (pressurized to 2015 psi), remove the shipping cap, place

on the extinguisher and attach the nitrogen hose.

Nitrogen cylinders with “T” handle

quick opening valve:

Remove small temporary ring (safety) pin and install large ring pin.

Install a lockwire seal (tamper indicator).

Nitrogen cylinders with handwheel or lever

actuated quick opening valve:

Leadwire seal must be installed

9.

Reattach the discharge hose to the extinguisher (tighten hand tight plus a ¼ turn). Properly

coil the hose onto the storage rack (see page 11). Reattach the shutoff nozzle firmly to the

hose and store it in the mount with the shutoff lever in the

closed

(forward) position.

10.

Record the service date on the inspection tag and place the extinguisher in its proper

location.