5

ANNUAL MAINTENANCE – SERVICE PROCEDURE

WARNING:

BEFORE SERVICING, BE SURE THE EXTINGUISHER AGENT CYLINDER IS NOT

PRESSURIZED. THIS PROCEDURE IS BEST ACCOMPLISHED WITH THE

EXTINGUISHER IN AN UPRIGHT POSITION AND ON A LEVEL SURFACE.

1.

Clean extinguisher to remove dirt, grease or foreign material. Check to make sure that the

instruction nameplate is securely fastened and legible. Inspect the cylinders for corrosion,

abrasion, dents or weld damage. If any damage is found, hydrostatically test in accordance with

instructions in CGA C-1 and C-6 and NFPA 10.

2.

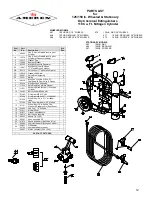

Inspect the extinguisher for damaged, missing or substitute parts. A careful inspection should

be made of the safety relief (MODELS 450, 451 & 452) to make sure that it has not ruptured,

corroded or been tampered with. ONLY FACTORY REPLACEMENT PARTS ARE APPROVED

FOR USE ON AMEREX FIRE EXTINGUISHERS.

3.

Check the date of manufacture printed on the extinguisher label (nameplate) or on the agent

cylinder dome. The agent cylinder, the discharge hose assembly and nitrogen supply hose

must be hydrostatically tested every 12 years. Test pressure:

a. Agent Cylinder – 500 psi (3447 kPa)

b. Hose Assembly – 300 psi (2068 kPa)

4.

Check the hydrostatic test date on the crown of the nitrogen cylinder. The nitrogen cylinder

must be retested in accordance with DOT regulations.

5.

Check the gauge on the nitrogen cylinder. If the pressure is below 1700 psig (11.7 mPa)

repressurize the cylinder to 2015 psig (13.9 mPa) or replace it. A low gauge pressure may

indicate leakage. Check for leaks. A low gauge reading may also result from low temperature.

See the temperature/pressure relationship chart in the Troubleshooting Guide. Check the

tamper indicator (lockwire seal) on the argon valve and replace if necessary.

6.

Wheeled extinguishers – Inspect the wheels to insure they rotate freely. Lubricate as required.

WARNING:

THE FOLLOWING STEPS SHOULD ONLY BE PERFORMED BY

PROFESSIONALLY TRAINED AND QUALIFIED SERVICE PERSONNEL THOROUGHLY

FAMILIAR WITH INDUSTRY SERVICE PROCEDURES AND SAFETY PRECAUTIONS AND

HAVING THE NECESSARY EQUIPMENT TO PERFORM THE SERVICE PROPERLY. ALL

EXTINGUISHER AND SERVICE EQUIPMENT COMPONENTS, FITTINGS AND ADAPTERS

MUST BE IN GOOD CONDIITON AND PROPERLY CONNECTED.