PN 16672

04/2020

8.

Install pull pin and new tamper seal.

9.

Install hose assembly, with shut

-

off nozzle attached, to the extinguisher cylinder discharge valve. Tighten

hose coupling ¼ turn after contact with hose gasket. Coil hose onto the hose rack and install nozzle into

mount.

10.

Weigh extinguisher to confirm that the total weight is within the tolerances indicated in the maintenance

section on the extinguisher nameplate.

11.

Record recharge date and attach new recharge tag in accordance with the requirements of the "Authority

Having Jurisdiction".

TROUBLE SHOOTING GUIDE

WARNING: DETERMINE THE SOURCE OF A LEAK BEFORE THE EXTINGUISHER IS

DEPRESSURIZED. THE EXTINGUISHER MUST BE COMPLETELY DEPRESSURIZED BEFORE ANY

ATTEMPT IS MADE TO REMOVE THE VALVE ASSEMBLY AND CORRECT THE LEAKAGE PROBLEM.

SEE INSTRUCTIONS PACKAGE WITH THE AMEREX HALOTRON l RECHARGE KIT PN 14538 FOR THE

PROPER METHOD OF DEPRESSURIZING THE EXTINGUISHER TO AVOID UNNECESSARY

DISCHARGE AND MINIMUM AGENT LOSS.

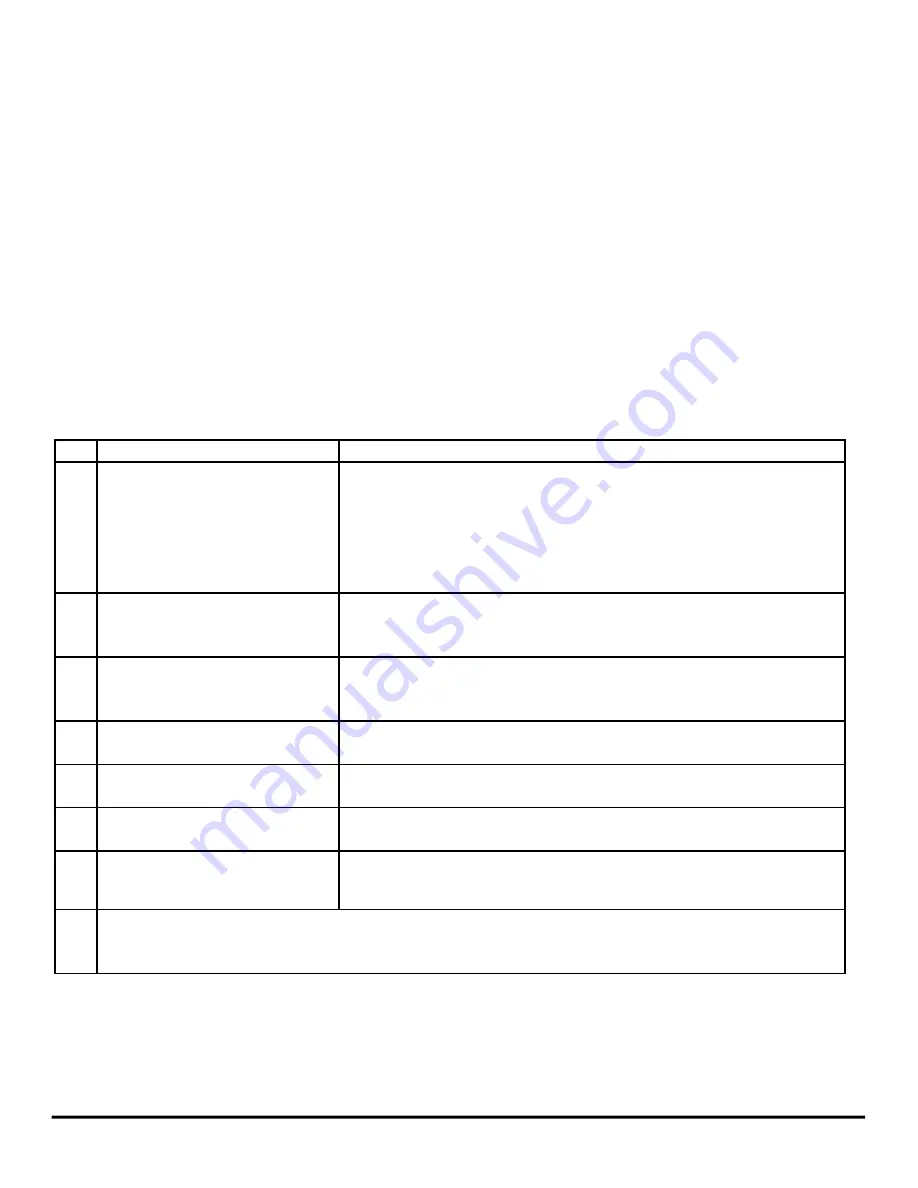

PROBLEM

CORRECTIVE ACTION

1.

Pressure gauge reads high or

low

Pressure variances in the gauge reading may be found if the extin-

guisher has been subjected to extremes of heat or cold. High tem-

peratures can cause high gauge readings and low temperatures,

low readings. When in doubt, condition the extinguisher to 70ºF

(21ºC) for several hours to obtain more accurate pressure gauge

readings.

2.

Leak through valve

Remove valve assembly, downtube, spring and valve stem assem-

bly. Install new valve stem (GREEN SEAL) assembly. Check valve

seat for scratches or foreign matter.

3.

Leak at collar o

-

ring

Remove valve assembly, clean collar o

-

ring seating surface thor-

oughly and lubricate lightly with V

-

711. Install new collar o

-

ring

(GREEN) after lubricating with V

-

711.

4.

Leak around gauge threads

Remove gauge* and reinstall using Teflon tape on the gauge

threads.

5.

Defective gauge

Remove defective gauge* and install a new gauge using Teflon

tape on the gauge threads.

6.

Leak in cylinder

Contact Amerex if under warranty, otherwise mark

“

REJECTED

”

and return to owner.

7.

Visible deterioration of dis-

charge hose

Replace hose assembly. Extinguishing agent has been stored in

hose for a prolonged time. See Caution in Shut

-

Down procedures.

*

Pressure gauge threads are coated with a special epoxy at the factory. For easy removal soak the

valve assembly in hot water (180° F/82°C) for two to four minutes. Remove gauge with a

7/16”

open

end wrench.

FOR REPLACEMENT PARTS SEE THE AMEREX PORTABLE AND WHEELED

PARTS BOOK PN 27277 AVAILABLE AT http://www.amerex

-

fire.com UNDER

MANUALS OF THE RESOURCE SELECTION.