98

HELIX™

Manual (P/N 26291)

Chapter 6: Recharge

Rev A (February 2018)

HELIX™

PCU Fire Suppression System

For Systems Using Electric Control Head (P/N 14032

-

R):

For systems using an Electric Control Head (P/N 14032

-

R), perform the following steps. The control

head must be disassembled, cleaned, and reassembled after each use.

Control Head Removal (See Figure 4.3.1):

1.

Unplug Linear Actuator (P/N 20500

-

R) from Linear Actuator circuit and unscrew Linear

Actuator from Control Head Body.

2.

Carefully remove Electric Control Head from Agent Cylinder Valve by removing (2) 5/16”

-

18

bolts.

3.

Install Shipping Plate (P/N 10099) in place of Electric Control Head (See Figure 2.1a).

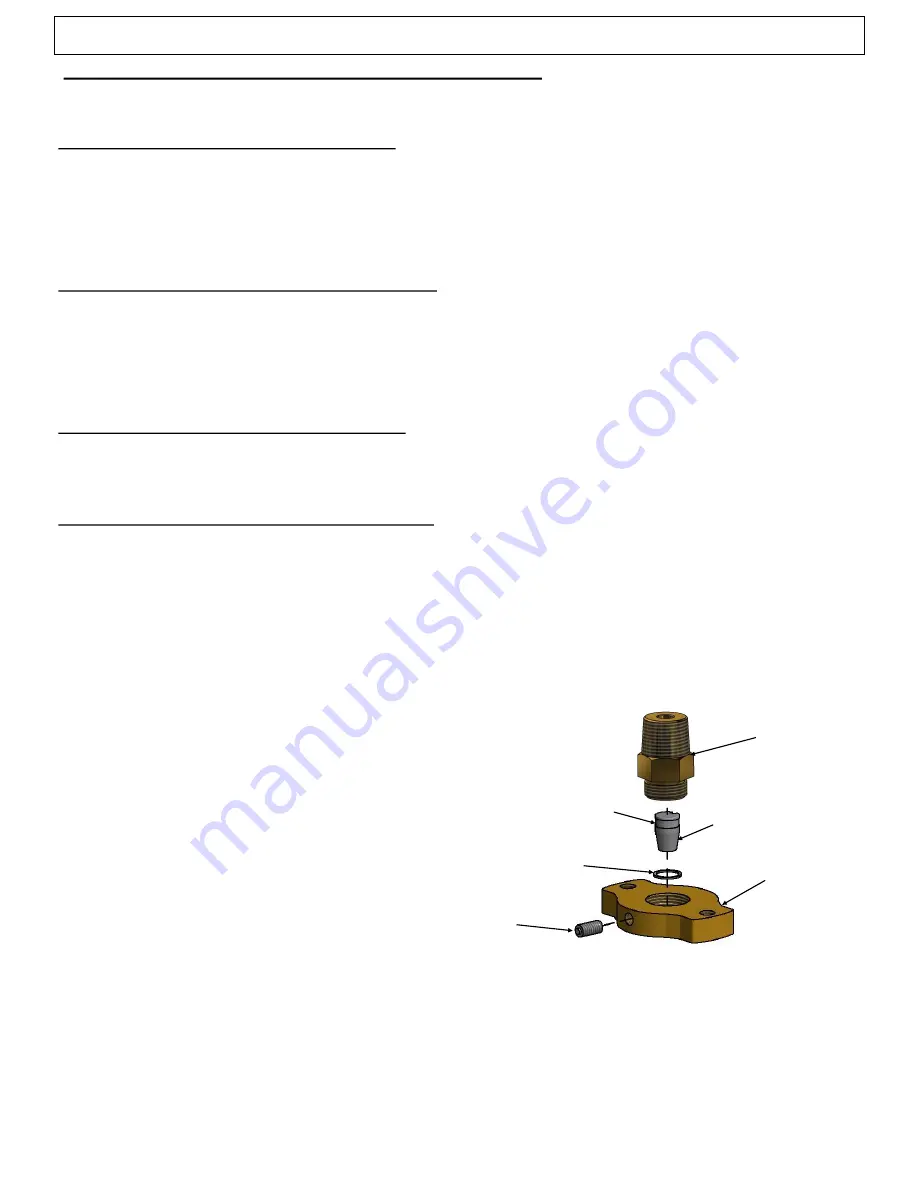

Control Head Disassembly (See Figure 6.2.1b):

4.

Remove the Set Screw (P/N 14038) from the Base (P/N 14034) using a 1/8” Allen Head

wrench.

5.

Unscrew the Body (P/N 26426) from the Base (P/N 14034).

6.

Remove the Piston (P/N 14035) and Retaining Ring (P/N 14037). Remove the Retaining Ring

from the Piston groove.

Control Head Cleaning (See Figure

6.2.1b

)

:

7.

Inspect and clean all components of the Control Head. If any scarring or damage has

occurred, replace the component. Stainless steel disc punched from spent Linear Actuator

(P/N 20500

-

R) must always be removed in the event of an automatic actuation.

Control Head Reassembly (See Figure 6.2.1b):

8.

Place Retaining Ring (P/N 14037) into Base (P/N 14034), followed by the Piston (P/N 14035)

in orientation shown.

9.

Before adding any thread lock, screw the Body (P/N 26426) into the Base and test the

assembly by using a Phillips head screwdriver inserted through the Linear Actuator port to

force the Piston through the Retaining Ring. Verify the Retaining Ring locks into the Piston

groove.

10.

After testing the control head, disassemble the

components by repeating steps 5 and 6. Repeat step 8.

11.

Apply one drop of medium grade

thread lock to threads of the Body (P/

N 26426).

Torque Body into Base to

200 in

-

lb (17 ft

-

lb) [23 Nm].

12.

Apply one drop of medium grade

thread lock to threads of the Set

Screw (P/N 14038). Thread screw

into Base until resistance is

met. Do

not over

-

tighten!

13.

Invert assembly and confirm that the

piston floats freely within the

assembly. Ensure the Retaining Ring

(P/N 14037) is not pinched between

the Body and Base.

BODY

(P/N 26426)

BASE

(P/N 14034)

SET SCREW

(P/N 14038)

PISTON

(P/N 14035)

PISTON GROOVE

RETAINING RING

(P/N 14037)

Figure 6.2.1b