31

HELIX™ Manual

(P/N 26291)

Chapter 3: System Design

Rev A (February 2018)

HELIX™ PCU

Fire Suppression System

3.4 Agent Distribution Network Design

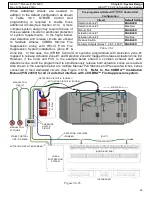

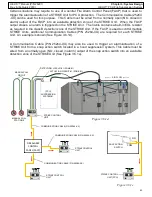

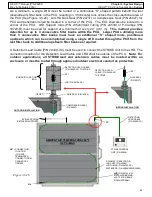

After determining Nozzle and Agent Cylinder quantities and location(s), the Agent Distribution

Network must be designed for transferring the Dry Chemical Agent to the Nozzles. This is

accomplished using hydraulic hoses, fittings, tees, and/or Distributor Blocks. Use the following

requirements for constructing the Agent Distribution Network:

Note: The following requirements are applicable to the Agent Distribution Network ONLY.

Refer to Section 3.5.2 for Pneumatic Actuation Network requirements.

•

After the Cylinder Bracket is installed, vertical Agent Cylinders must be installed with the

discharge outlet facing the

direction that will allow the Discharge Fitting Kit to be easily

connected to the Agent Distribution Network (See Figure 4.2.1).

•

The Agent Distribution Network must be secured to the PCU at a maximum of 24” intervals with

use of padded “P” clamps.

•

The Agent Distribution Network must be routed in such a manner that the

network does not

interfere with routine maintenance.

•

The installer must be aware of maximum ambient temperature ratings for hose selection and not

to exceed those temperature ratings during normal equipment operation.

•

When installing the Agent Distribution Network, the installer must comply with the hose

manufacturer’s minimum hose bend radius requirements. Avoid pinch points or possible chafing

of the network.

•

The number of Nozzles used in the Agent Distribution Network must match what is specified in

Table 3.3 for the Agent Cylinder used.

•

The installer must not exceed the Agent Distribution Network limitations as shown in this section.

See Sections 3.4.1 thru 3.4.3 for Agent Distribution Network configurations.

•

Use PTFE thread tape for NPT connections in the Agent Distribution Network.

•

Elbows may be used in a 45° or 90° configuration but cannot exceed quantities as shown in the

Tables in Sections 3.4.1 thru 3.4.3.

•

All hoses used must meet or exceed SAE 100 R5 or 100 R1 (minimum) hose specifications.

Hoses must have operating temperatures of –65°F to + 200°F (

-

54°C to +93°C).

•

All hose end fittings must be only those specified by the hose manufacturer.

•

All fittings (elbows, tees, reducers, couplers…etc.) used for connection of the Agent Distribution

Network must be minimally rated for use at the maximum Agent Cylinder operating pressure. If

fittings are located in a corrosive environment, appropriate fitting material must be considered.

•

Reference the following list of applicable standards:

SAE J1273

SAE J516

SAE J517

SAE J343