60

HELIX™ Manual

(P/N 26291)

Chapter 4: System Installation

Rev A (February 2018)

HELIX™ PCU

Fire Suppression System

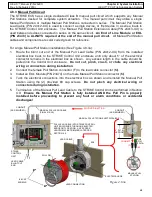

4.7.6 LHD Connector Installation

LHDs are supplied with an uninstalled male connector on the downstream side (opposite end from

STRIKE Control Unit) to facilitate installation through any LHD Quik Seals.

Only after the LHD is

installed through

any LHD Quik Seals can the included male connector be installed on the

LHD.

Install the male connector per the following instructions:

1.

Each LHD is supplied with an uninstalled, bagged male connector and connector lock (See

Figure 4.7.6a). Locate these items.

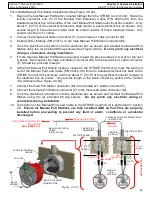

2.

Insert both LHD sockets into the seals on the back of the male connector.

Both sockets must

be inserted at the same time

(See Figure 4.7.6b). Insert fully until a “click” is heard for each

and the sockets are flush with the front of the connector face (See Figure 4.7.6c).

3.

Insert the included connector lock into the slot on the front of the connector. The lock will snap

into place and is fully installed when in contact with the connector face (See Figure 4.7.6d).

4.

The connector is fully installed. EOL Modules, or additional detection devices, or extension

cables may now be connected to this connector.

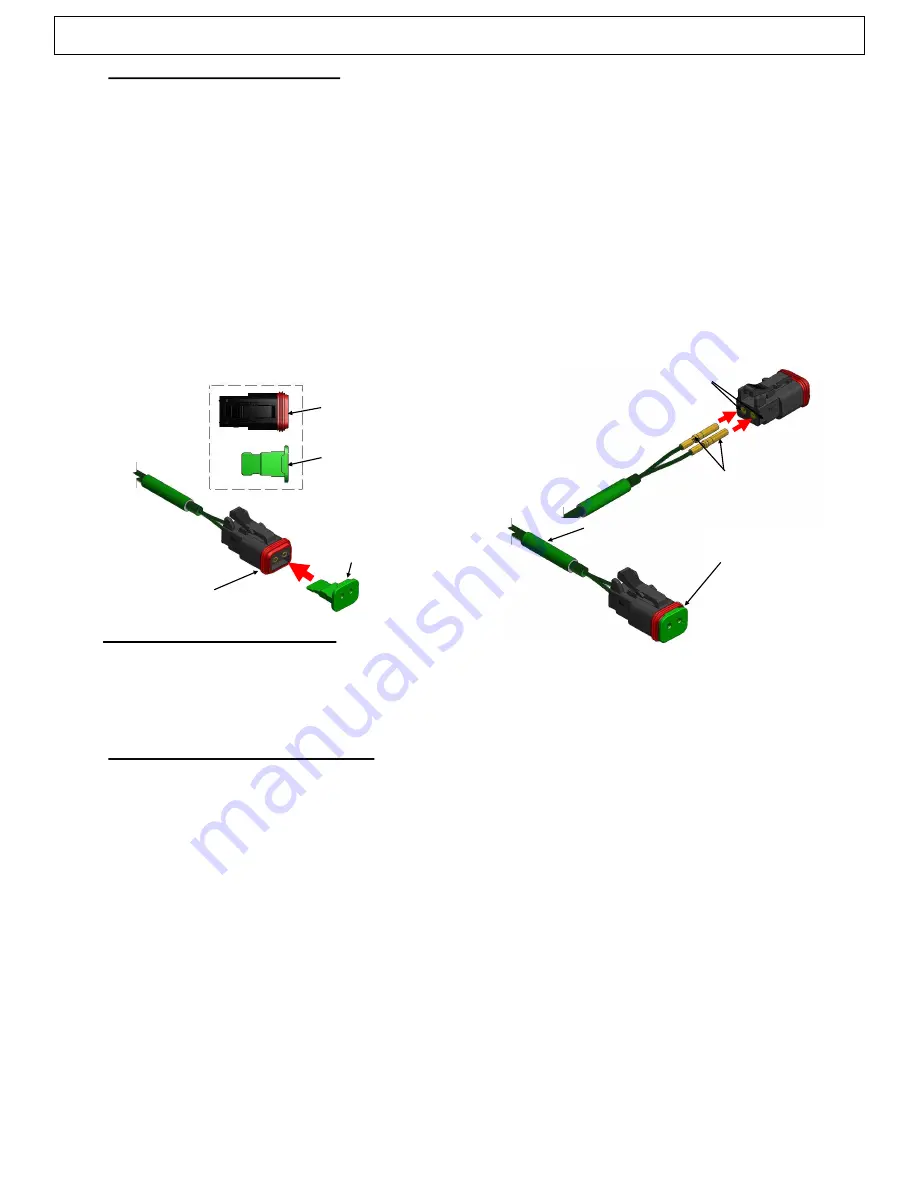

Figure 4.7.6c

CONNECTOR LOCK

BOTH SOCKETS FLUSH

WITH CONNECTOR FACE

MALE CONNECTOR

CONNECTOR LOCK

LHD SOCKETS

CONNECTOR SEALS

CONNECTOR LOCK

FLUSH AGAINST

CONNECTOR FACE

Figure 4.7.6a

Figure 4.7.6b

Figure 4.7.6d

LHD (P/N 24744

-

XX)

4.7.7 Linear Actuator Installation

Refer to section 4.3 for installation of the Linear Actuator (P/N 20500

-

R) into the Electric Control

Head (P/N 14032

-

R). Refer to section 4.5 for installation of the Linear Actuator (P/N 20500

-

R) into

the Electric Nitrogen Actuator (P/N 20775

-

R).

4.7.8 Manual Pull Station Installation

The Amerex STRIKE ECS requires at least one Manual Pull Station (P/N 24168 or 24290) be

installed. Manual Pull Stations must be installed indoors and no higher than 48 inches (1.21 m) from

the floor and must be located along a path of egress. Consult the local AHJ for final approval for

quantity, locations, mounting heights, and all other considerations prior to installation.

Mounting locations shall permit easy access to a Manual Pull Station in the event that it must be

used. The assembly must be mounted to a solid structure capable of supporting the weight of the

assembly and additional wiring components as well as capable of handling the potential force

applied to the station when pulled manually. Proper cable routing should be considered when

choosing an appropriate location. Any obstacles, moving parts, hazard areas, or walls that may

inhibit access or cause damage to the Manual Pull Station must be avoided. Mount the Manual Pull

Station in an area protected from the outside environmental conditions.

The Manual Pull Station is available in two mounting configurations: surface mounted (P/N 24290) or

flush mounted (P/N 24168). An electrical outlet/conduit box is provided with each unit to house the

electrical wiring, connectors and EOL. This electrical box contains knockouts which are used for all

field wiring to and from each Manual Pull Station.