HICLAVE

HG-SERIES AUTOCLAVES

(HG-50 and HG-80)

OPERATION MANUAL

Before using this Autoclave, please read this manual

and follow all Safety Rules and Operating Instructions

.

3951C Industrial Way Concord, CA 94520

(925) 299-0743 / (888) 263-7392 ∙ Fax:(925) 299-0745

marketing@amerexinst.com ∙ www.amerexinst.com

Summary of Contents for Hirayama HG-50

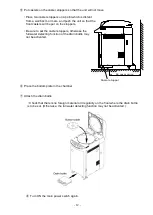

Page 8: ... 7 HG 80 External View ...