9

SIDE THRESHOLD PLUMB LINE

TIME REQUIRED

½ HR

6

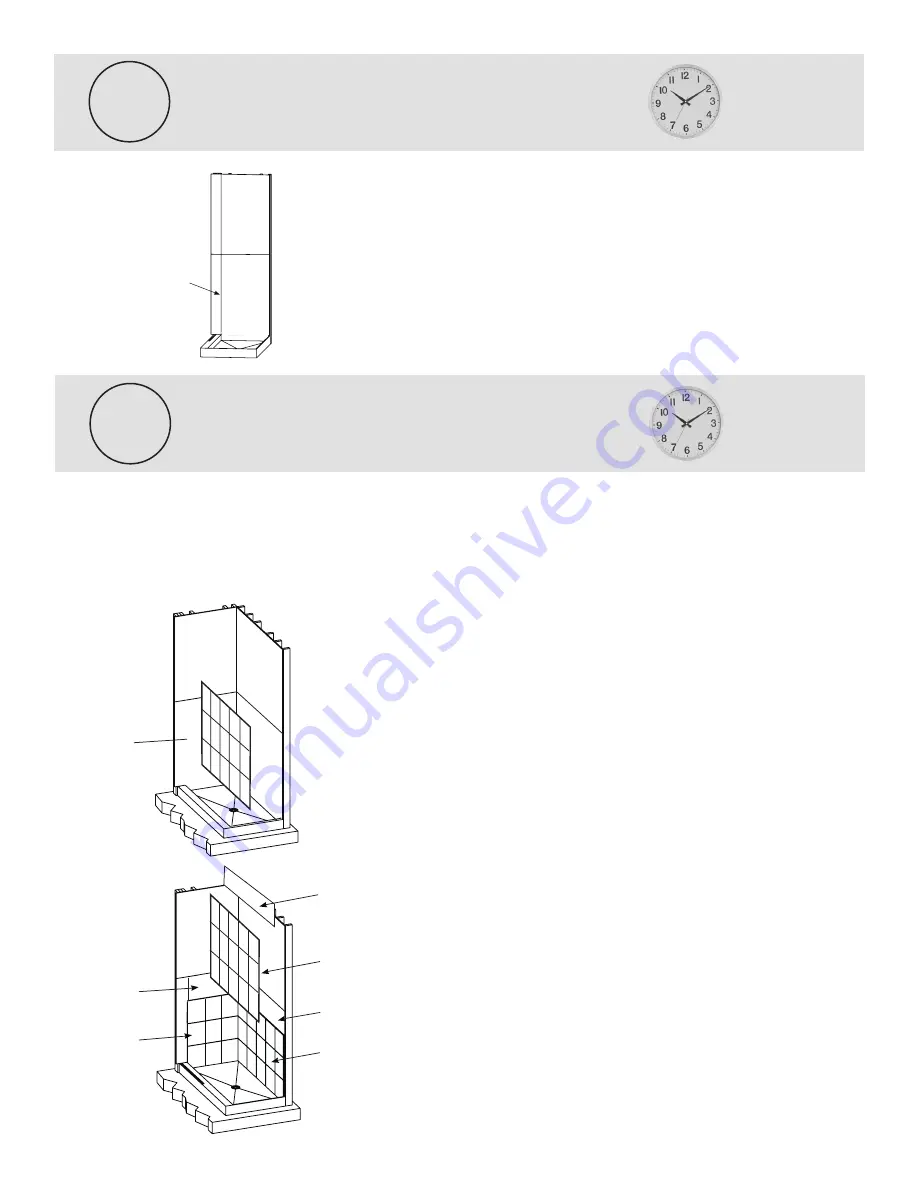

To help with the wall installation, use a level and draw a plumb line from the inside of the floor

threshold up to the top of the shower. Do this on both sides. This line will be where the side threshold

and the wall panels meet, this will give you a visual reference point when dry-fitting your wall panels.

WALL PANEL/LINER INSTALLATION

TIME REQUIRED

3-4 HR

A - Inspecting Wall Panels/Liners

Inspecting panels at this point will give you confidence that the wall panels are straight and square from the factory. When installing wall panels, you may need to

make adjustments to the panels to accommodate for unevenness of your existing walls. During the inspection process and/or dry-fitting process, if you have any

concerns about the alignment or fit of the wall panels, please call 1-800-454-2284 for customer service, and we will gladly assist you with your installation.

1. Find a large empty area to layout and inspect all panels.

2. Align all panels and liners to check for straightness. Make sure grout lines are straight and square

to each other.

3. Sistine Stone wall panels are made to be flexible. (Warning - Store on a flat area.) If wall panels

have been stored improperly or seemingly have become extensively bowed, they can be easily

flattened before installation

(See troubleshooting section on last page for details).

B - Test Alignment by Dry-fitting Wall Panels/Liners

1. Place your first bottom panel 2B into position.

(diagram 7).

Rest 2B panel onto the pan floor;

use spacers between the floor and the panel to make the top of the panel level.

2. Place the second bottom panel 1B into position, push the two panels together. Make sure the

grout lines are aligned, use spacers to make the top of the panel level. Inspect the spacing

between the wall panels and the side threshold plumb line.

3. Depending on your cement board alignment, some sanding of the wall panel edges may be

required for a tight fit.

4. Place liners 1L and 2L in position check for level and length.

5. Place 2T into position.

(diagram 8)

6. Place 1T into position. Depending on your faucet selection, you may need to mark and cut out

holes for your faucet to fit through before you can place the panel into position. Remember

“measure twice, cut once”, you can cut our walls with most cutting tools. (See installation

video at www.americanbathfactory.com). Now you can check for level, grout line alignment and

spacing between walls and plumb line.

7. Check that 1LT & 2LT (top liners) fit properly on top.

10

plumb line

(draw both sides)

diagram 6

2B

diagram 7

diagram 8

1B

2B

2T

2L

1L

2TL