44

SECTION VIII

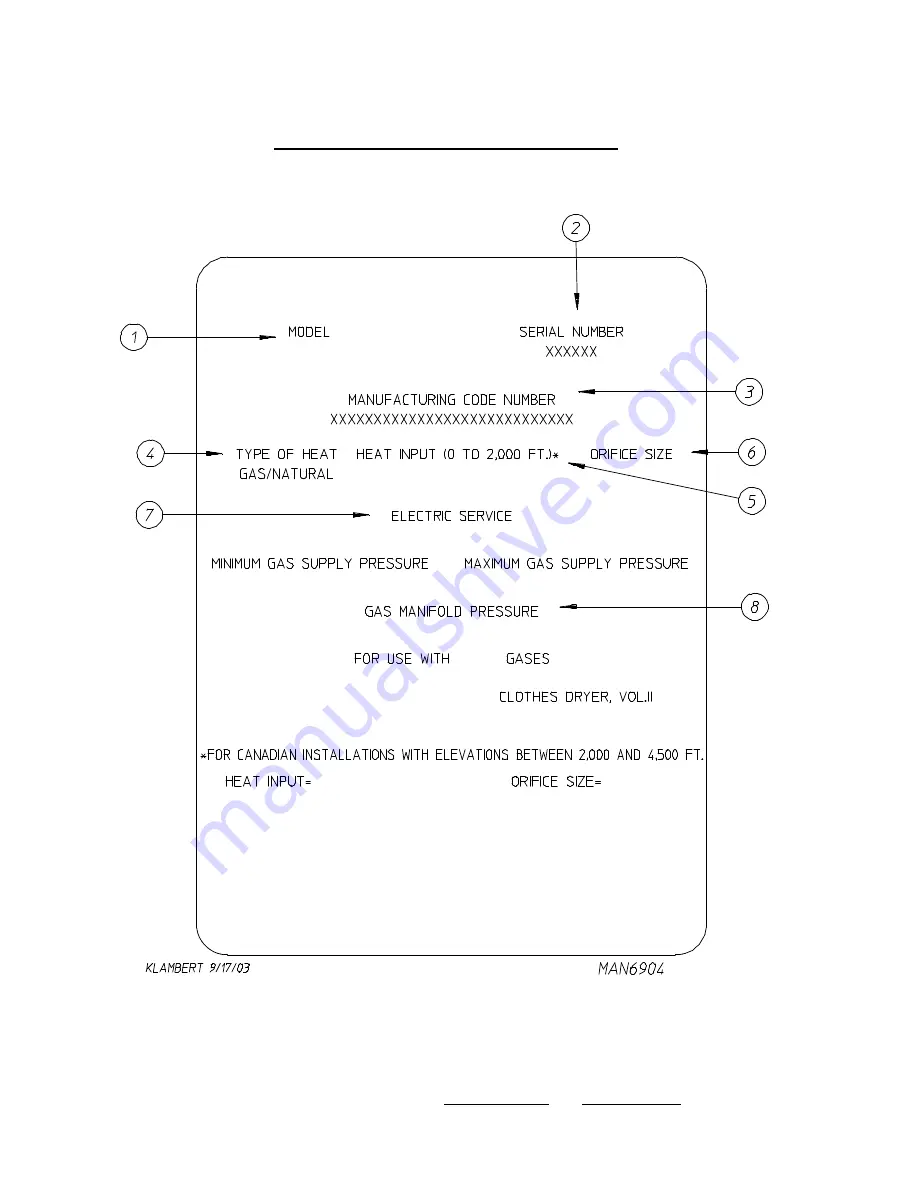

DATA LABEL INFORMATION

When contacting

American Dryer Corporation

,

certain information is required to ensure proper service/parts

information from

ADC

. This information is on the data label located on the left side panel/wall area behind the

control door. When contacting

ADC

, please have the

model number

and

serial number

available.

Summary of Contents for ML-75V Phase 7

Page 21: ...17 ...

Page 58: ...ADCPartNo 113236 4 05 26 05 2 ...