6

Class 3 Compressor Owner’s Manual

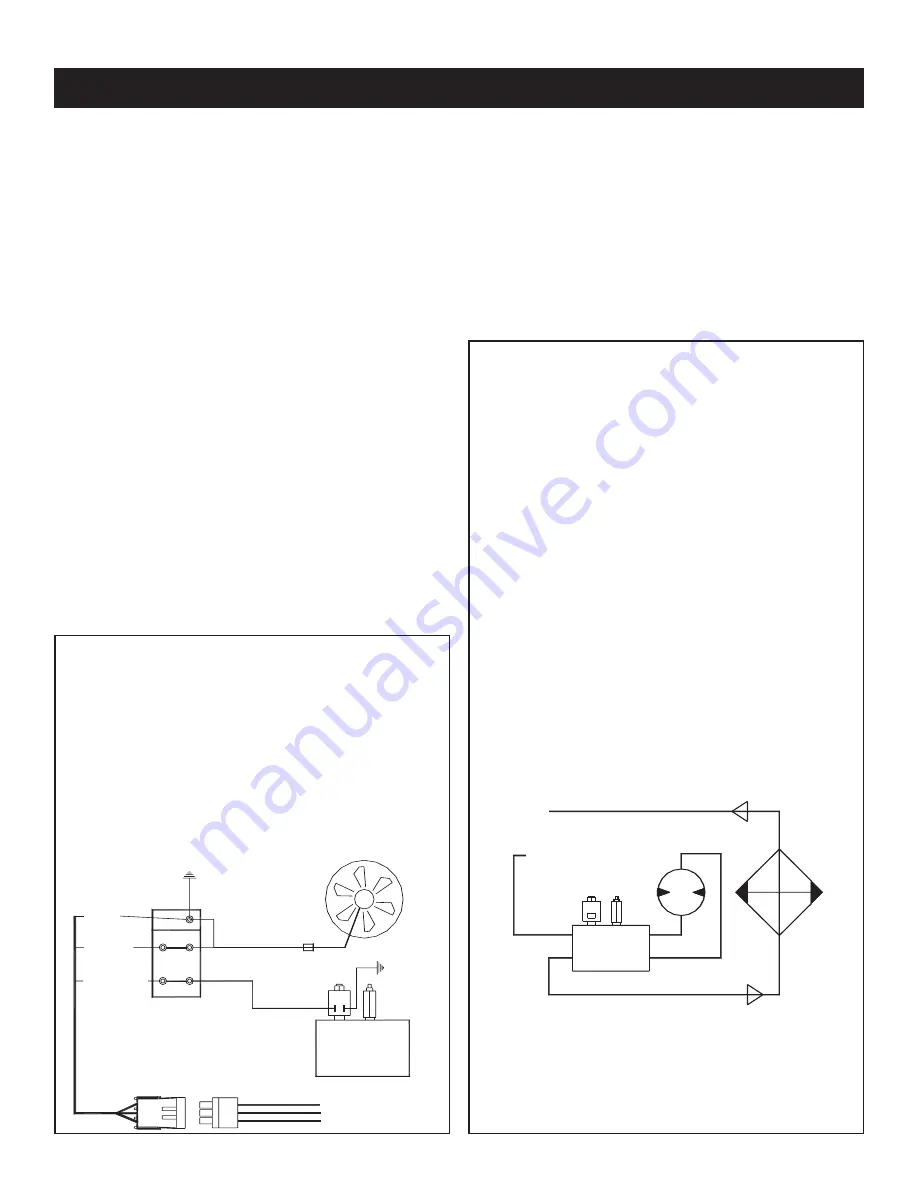

Return Line

Pressure

Line

FAN

GND

CPRSR

SPD CTRL

PRESSURE

SWITCH

LINE

MOTOR

HYDRAULIC

MANIFOLD

COMPRESSOR (12V INPUT)

GROUND

SPEED CONTROL

C

B

A

C

B

A

SHD-43 Installation

Pump Assembly:

The pump assembly may either be installed directly

on the PTO or as an optional method, may be

driven by a driveline from the PTO. Pump

manufacturers provide specific installation

information for their products and should be

consulted if questions arise.

PTO Assembly:

Check with the PTO manufactures representative

for specific instructions regarding your particular

make, model, and year of vehicle. As some trucks

may require modification of the transmission cross

member and the exhaust system, the

manufacturer’s instructions should be followed to

insure proper installation of the PTO.

Compressor Assembly:

Prepare the mounting location of the compressor

by locating and drilling four (4) holes, 7/16”

diameter as per the mounting pattern of the air

compressor base. Using four (4) 3/8” x 1.25 GR-5

cap screws, 3/8” flat washers, and 3/8” nyloc nuts,

secure the compressor in place. The compressor is

air cooled, and must have a clean supply of

cooling air to the fan with minimum restrictions.

Adequate space must be provided for proper

circulation of air.

Electrical Connections:

From the air pressure switch there are two (2) wires,

red and black, running to the outside of the

compressor housing. Connect the black wire to the

vehicle frame or other suitable ground. Mount a

single throw toggle switch in a convenient location

and connect the red wire from the compressor to

this switch. Connect the other switch terminal to a

fuse holder and then to a 12-volt power supply. A

third wire is required from the air compressor switch

when connecting the speed control into the

system. (See drawing below)

Electric speed control:

An optional electric or electronic speed control

must be used to maintain proper operating speed

of the air compressor. The engine speed control will

automatically increase from idle to preset speed

when engaged and decrease when disengaged.

The electric cable pull speed control American

Eagle P/N 25740 is used on most gasoline engines.

The electronic speed controls are used only on Ford

7.3 and 6.0L diesel engines. Proper installation

instructions are provided with each system.

Hydraulic System:

The hydraulic system consists of the pump, oil

reservoir, filters and hoses. Installed on the

compressor is a valve block assembly that controls

the flow to the hydraulic motor. To this block, a 1/2”

high-pressure hose must be attached. This hose

comes from the hydraulic pumps pressure side. A

3/4” minimum low-pressure return line is connected

to the oil cooler outlet and is routed to the oil

reservoir. American Eagle recommends a sufficient

sized reservoir be provided which includes the

proper suction and return filters. The cooler on the

compressor is designed and sized to cool the air

compressor efficiently. An auxillary oil cooler is

required when additional hydraulically operated

equipment are added to the hydraulic system.

Pressure on the return line exceeding 200 PSI can

and will cause damage to the filter, cooler, and

components of the compressor hydraulic system.