Assembly Drawings

17

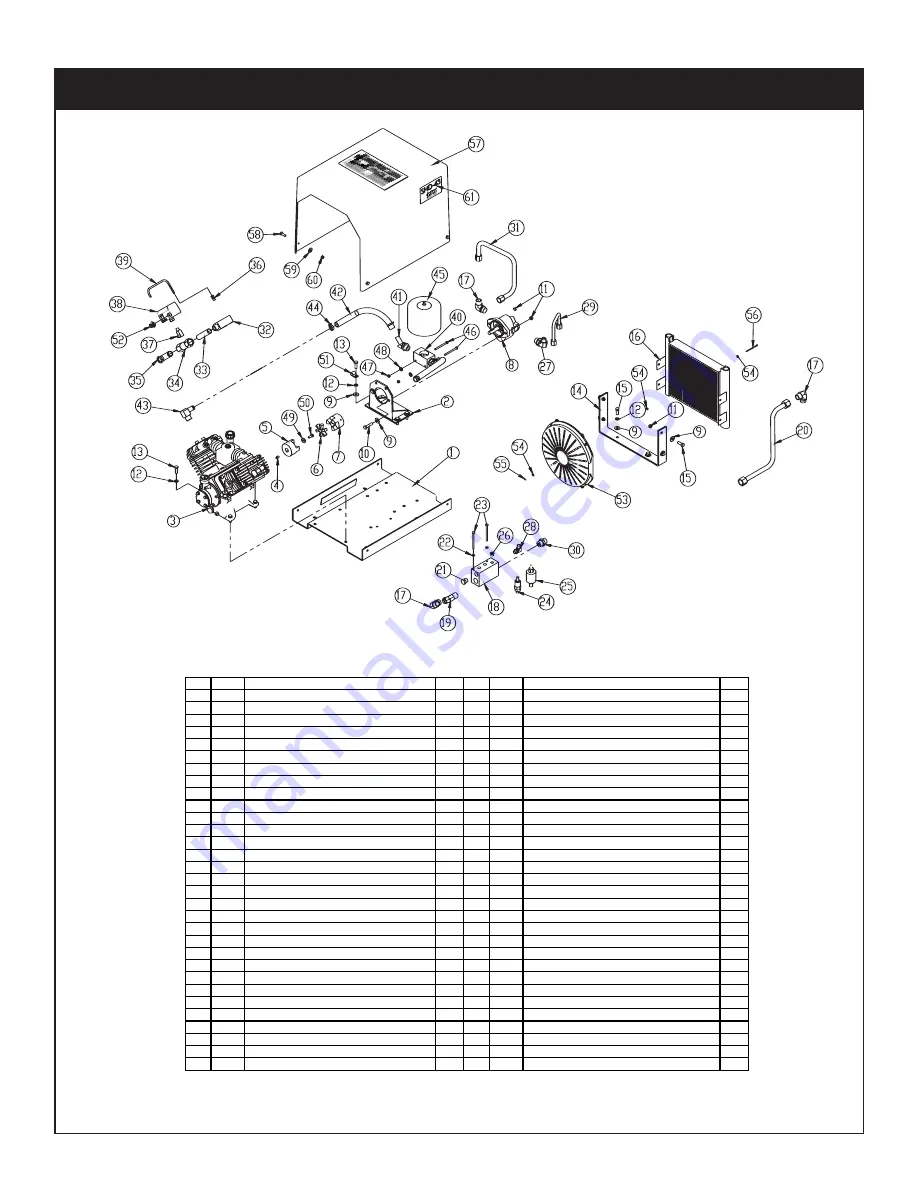

SHD-43 Compressor Assembly

ITEM PART DESCRIPTION

QTY. ITEM PART DESCRIPTION

QTY.

1

B0820 BASE WLDMNT SHD 60

1

32

8278

FTG ST L 0.75 MNPT/0.125 FNPT SPL

1

215967 MOTOR MNT SHD 60 & SHD 43

1

33

4581

NIPPLE 0.75X4.00 BLK PIPE

1

314265 CPRSR V360CT66NP

1

34

5480

VALVE CHECK 0.75 STANDARD

1

4

C4703 KEY WOO DRUFF 5/32 X 3/4 #8

1

35

C6150 ST EL ML/FM PIPE 2102-12-12

1

5

C3480 COUPG HYD CPRSR TAPER

1

36

C 6243 FTG CPRSN 0.12NPT/0.25 TUBE

1

6

C4779 COUPG SPIDER SUL 99 BLUE URETHANE 1

37

8276

FTG ML ELBOW 0.25 MNPT/0.125 MNPTSPL 1

7

C4781 COUPLING LOVEJOY 5/8

1

38

C0863 SWITCH PRES COMPRESSOR

1

8

C4492 MOTOR HYD SHD60 & SHD43

1

39

15046 TBE AIR .25X9.00

1

9

C6353 WASHER 0.38 FLAT GR8

12

40

12180 FILTER MANIFOLD SHD60 CPRSR

1

10

C0944 CAP SCR 0.38-16X1.75 HHGR5

2

41

C4794 NIPPLE O'RING 45 4603-12-12

2

11

0347

NUT 0.38-16 HH NYLOC

6

42

14600 HOSE SUCTION 0.75 X 13.00

2

12

0523

WASHER 0.38 LOCK

10

43

13638 FTG HOSE BARB 0.75 HOSE X 0.75 90DG

2

13

0335

CAP SCR 0.38-16X1.25 HHGR5

8

44

13577 CLAMP UNI 1.19 O.D. 5019

4

14

B0682 BRKT COOLER MOUNT SHD60

1

45

13529 FILTER AIR SHD60

1

15

0351

CAP SCR 0.38-16X1.00 HHGR5

6

46

0482

CAP SCR 0.25-20 X 3.00 HHGR5

2

16

C1129 COOLER OIL

1

47

0333

NUT 0.25-20 HHGR5 NYLOC

2

17

C6145 FTG 90 DEG

3

48

0340

WASHER 0.25 FLAT

4

18

C3558 MANIFOLD BLOCK SHD60

1

49

D1465 WASHER 0.31-0.178 THICK

1

19

C6379 FTG SWIVEL NUT ELBOW 12-C6X-S

1

50

C4570 CAP SCR 0.31-24X0.75 HH NF

1

20

C4766 TUBE ASM 0.75 MANIF TO CLR SHD60

1

51

C0081 CLAMP 0.50 BLK VINYL

1

21

C2322 PLUG 1/2 STR THRD 8-P5ON-S

1

52

C5616 CLAMP ROMEX 0.50

1

22

0521

WASHER 0.25 LOCK

2

53

C6359 FAN 12.00 PULL 12 VOLT

1

23

0483

CAP SCR 0. 25-20 X 3.50 HHGR5

2

54

5290

W ASHER #8 SAE FLAT ZP

6

24

C4914 VALVE RELIEF CP-200-1-B-0-A-C

1

55

D0076 NUT #6-32 HH NYLOC

2

25

C4499 VALVE SOLND

1

56

D0075 SCREW #6-32X2.75 RH HD MACHINE

2

26

C4961 PLUG STR HOLLOW HEX 0.38 6-HP5ON

1

57

C4695 HOOD F/G SHD60

1

27

C4671 FTG 8-12 C50X JIC 90 DEG

1

58

C0922 CAP SCR 0.31-18X1.00 HHGR5

4

28

C4501 FTG 8 C50X 90 DEG ELL

1

59

0343

WASHER 0.31 FLAT

4

29

C2297 TUBE ASM 0.50 MANIF TO MOTOR SHD60 1

60

0342

NUT 0.31-18 HH NYLOC

4

30

C4498 FTG ORB/JIC STRT CONNT 12-F5OX-S

1

61

D0993 DECAL SHD43

2

31

C4954 TUBE ASM 0.50 MANIF TO MOTOR SHD60 1

COMPRESSOR ASSEMBLY