9

Maintenance

9

High aging stability

High disperse capacity

Low emulsification tendency

Flash point: above 400°F/ 200°C

Pour-point: 5° below lowest ambient temperature

minimum

Minimum foaming

High corrosion protection

Hydraulic or turbine oil

Basic oil: solvate

Operating temperature: up to 230°F / 110°C

Viscosity class: ISO VG 68

Viscosity at 104°F / 40°C: ca. 42-50 mm2/s (cST)

Oil Requirements

Screw compressors must be operated using the

most suitable oil for operation. The compressor man-

ufacturer must approve this oil for use. The oil must

also be suitable for use in unfavorable conditions

such as: contamination of the intake air by gases,

solvent vapors, exhaust gases, and high ambient

temperature conditions.

Suitable types and brands of oil may be specified

on request. Suitable screw compressor oils can be

mineral oils, synthetic oils, and biological degrad-

able oils.

The substances and materials used in the compres-

sor such as seals must be taken into account when

selecting the types of oil. Corrosion or other material

degradation must not occur.

Important: Do not mix different types of oil.

Important: In the case of ambient temperatures

close to freezing, prevent the unit from freezing.

Pipeline Materials:

The oil used in screw compressors can degrade

plastics used in air pipelines.

Oil Recommendation

WARNING: COMPRESSOR MUST BE STOPPED AND ALL AIR RECEIVERS DISCHARGED BEFORE

CHANGING OIL. COMPRESSOR OIL IS HOT, ABOVE 175 DEGREES F (80 DEGREES C) AND

CAN CAUSE BURNS.

Note: Change the oil with the compressor at operating temperature of 140-175 degrees F

(60-80 degrees C).

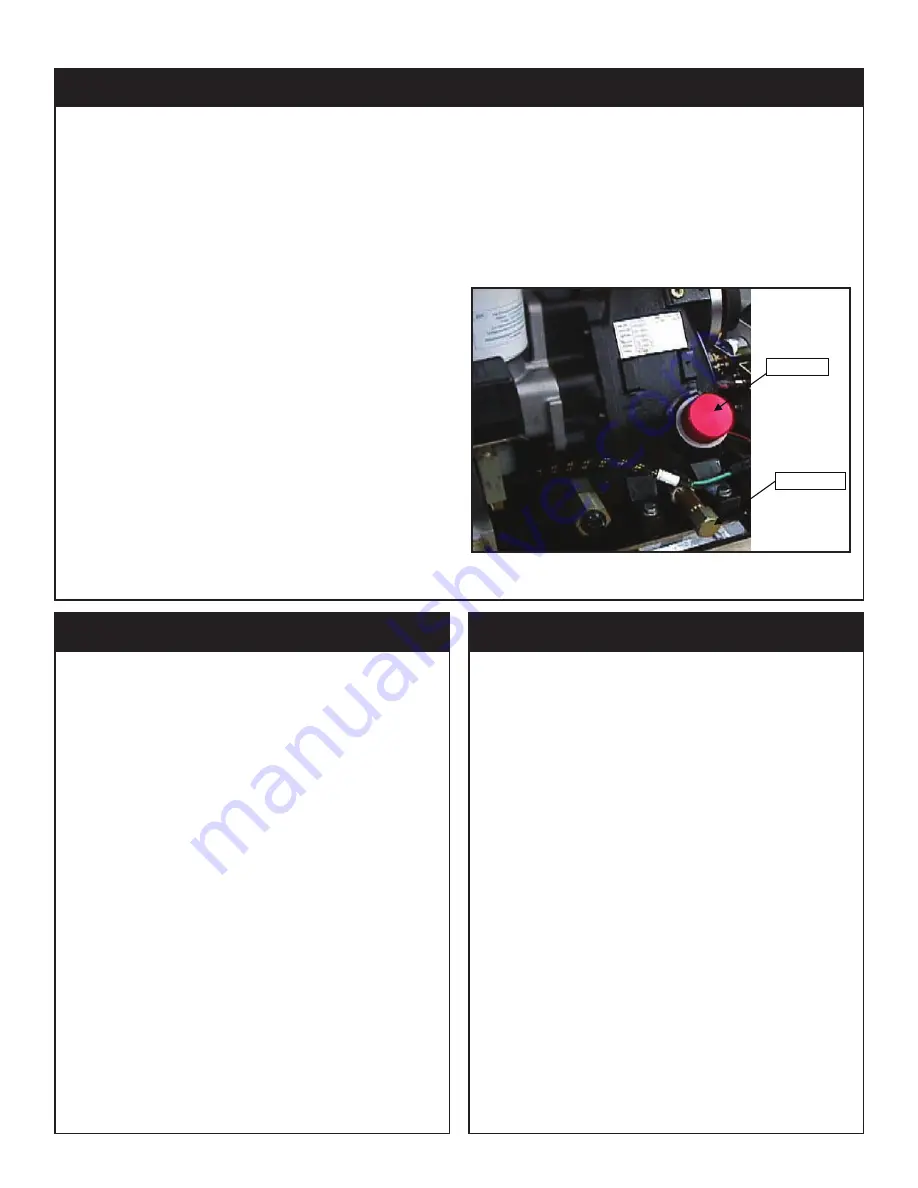

1. Turn off the compressor, hydraulic system

and truck engine to ensure that compres-

sor is not started.

2. Discharge air receiver.

3. Wait for one full minute.

4. Slowly unscrew the oil fill cap on the com-

pressor case.

5. Place a container under the oil drain pipe

and carefully unscrew the oil drain cap.

6. Drain the oil from the compressor case,

then replace and tighten oil drain cap.

7. Refill with oil to maximum level and replace

oil fill cap. Oil capacity is 4 quarts.

8. Operate compressor for 3 minutes.

9. Check oil and fill to maximum if necessary.

Changing the Oil

OIL FILL

OIL DRAIN

Summary of Contents for SRS-40

Page 2: ...SRS 40 Manual Revisions...

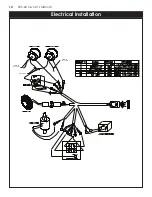

Page 8: ...4 SRS 40 Owner s Manual...

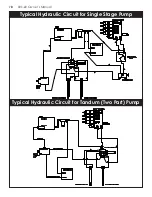

Page 24: ...20 SRS 40 Owner s Manual...

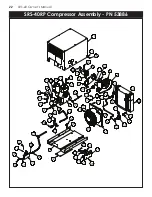

Page 32: ...28 SRS 40 Owner s Manual...

Page 34: ...30 SRS 40 Owner s Manual...