5

Operation

5

Chapter 3 - Operation

Before Start-Up

Inspect unit for any visible signs of damage.

Check the oil level in the compressor (See Section “Changing the Oil”). If oil is needed,

use American Eagle synthetic compressor oil (P/N C0087) or an equivalent synthetic oil.

Check hoses (air and hydraulic) for weak or worn condition and make sure that all con-

nections are secure.

Check the air intake filter to make certain that it is clean and unobstructed. A dirty air filter

is a possible cause of reduced air output.

Each compressor is bench tested under load at the factory to ensure proper operation.

While it is not necessary to follow any break-in procedure, the following checks should be

made before putting the unit into service and periodically during use.

General Information

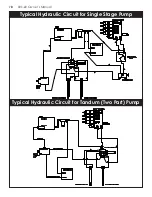

To use the compressor, start the vehicle

engine and engage the hydraulic system.

The compressor can now be activated

using the compressor switch. This energizes

the hydraulic solenoid sending oil to the

hydraulic drive motor and starts the com-

pressor. The system will now function auto-

matically. Once engaged, adjust the

engine speed control to ensure that the

compressor speed does not exceed 8000

Rpm under load. Adjustment instructions are

provided with the speed control unit.

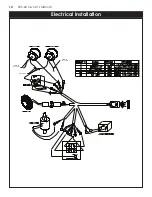

Air Operations(SRS-40RP & SRS-40E)

Activating the compressor switch sends

power to the cooling fan, hydraulic solenoid

valve and normally closed terminal (87A)

on the Bosch relay. The normally open

hydraulic solenoid valve closes, sending

hydraulic oil to the motor operating the

compressor. The fan and compressor oper-

ate whenever the hydraulic system is

engaged and the compressor switch is on.

Power from the common terminal (30) on

the Bosch relay goes to the line terminals on

the compressor pressure switch. If the air

pressure is below the kick out pressure (115

psi minimum/120 psi maximum) the pressure

switch closes sending power to the engine

speed control and compressor air inlet sole-

noid valve. The engine speeds up and the

compressor begins pumping air. When the

air pressure reaches the kick out pressure

setting (145 psi minimum/150 psi maximum)

the pressure switch opens, shutting the air

inlet valve and deactivating the speed

control.

The compressor is protected by an air pres-

sure and compressor oil switch gauge. The

coil on the Bosch relay is grounded through

these two switch gauges. If the air pressure

or compressor oil temperature exceeds the

switch gauge settings they close, complet-

ing the circuit and energizing the relay coil.

The normally closed switch on the Bosch

relay opens cutting power to the compres-

sor pressure switch. The compressor stops

pumping air and the engine slows down.

The switch gauges are set at the factory

and should not be adjusted.

Summary of Contents for SRS-40

Page 2: ...SRS 40 Manual Revisions...

Page 8: ...4 SRS 40 Owner s Manual...

Page 24: ...20 SRS 40 Owner s Manual...

Page 32: ...28 SRS 40 Owner s Manual...

Page 34: ...30 SRS 40 Owner s Manual...