7

Maintenance

7

Chapter 4 - Maintenance

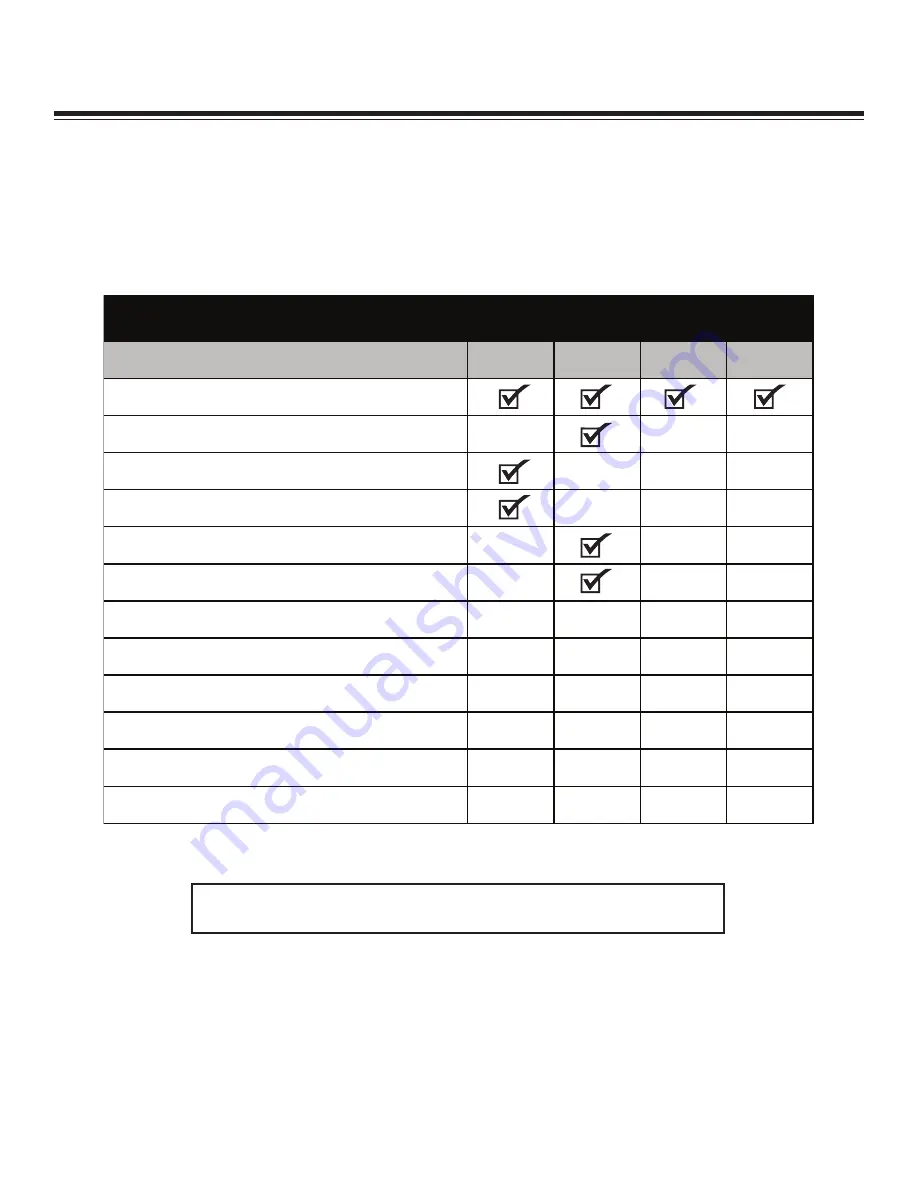

The following table is a list of routine maintenance items, including service intervals. Service

intervals are listed as hours, days, or weeks, whichever occurs first. American Eagle recom-

mends that these service intervals be followed. Before performing any maintenance func-

tion, turn off compressor, hydraulic system, truck engine and remove keys to assure that

compressor is not started. Be sure all air pressure in unit is relieved. Failure to do so may

result in injury or equipment damage.

General preventative maintenance includes maintaining proper fluid level in both systems and the general

cleanliness of the equipment. Proper fluids according to the specifications are required.

USE AE SYNTHETIC COMPRESSOR OIL P/N C0087. COMPRESSOR

CRANKCASE CAPACITY IS 3 QUARTS.

Maintenance Schedule

Daily

Weekly

Monthly

Hourly

Drain air tanks.

Check compressor case oil level.

Check fittings and airlines.

Check hydraulic fluid level.

Inspect and clean air intake filters.

100

Check oil cooler. Clean as needed.

Replace coalescering/separator cartridge.

12

3000

Change compressor oil and oil filter.

6

1000

Replace hydraulic filter.

6

Replace air filter.

3

100

Tighten all fittings and fasteners.

3

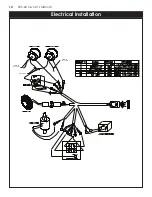

Check all electrical connections.

3

Service Intervals

Summary of Contents for SRS-40

Page 2: ...SRS 40 Manual Revisions...

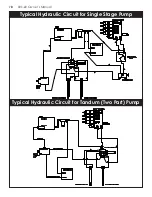

Page 8: ...4 SRS 40 Owner s Manual...

Page 24: ...20 SRS 40 Owner s Manual...

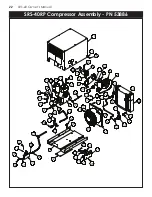

Page 32: ...28 SRS 40 Owner s Manual...

Page 34: ...30 SRS 40 Owner s Manual...