16

GUIDELINES FOR EXHAUST VENTING SYSTEMS DESIGN, CONT……

CHIMNEY AND VENTING

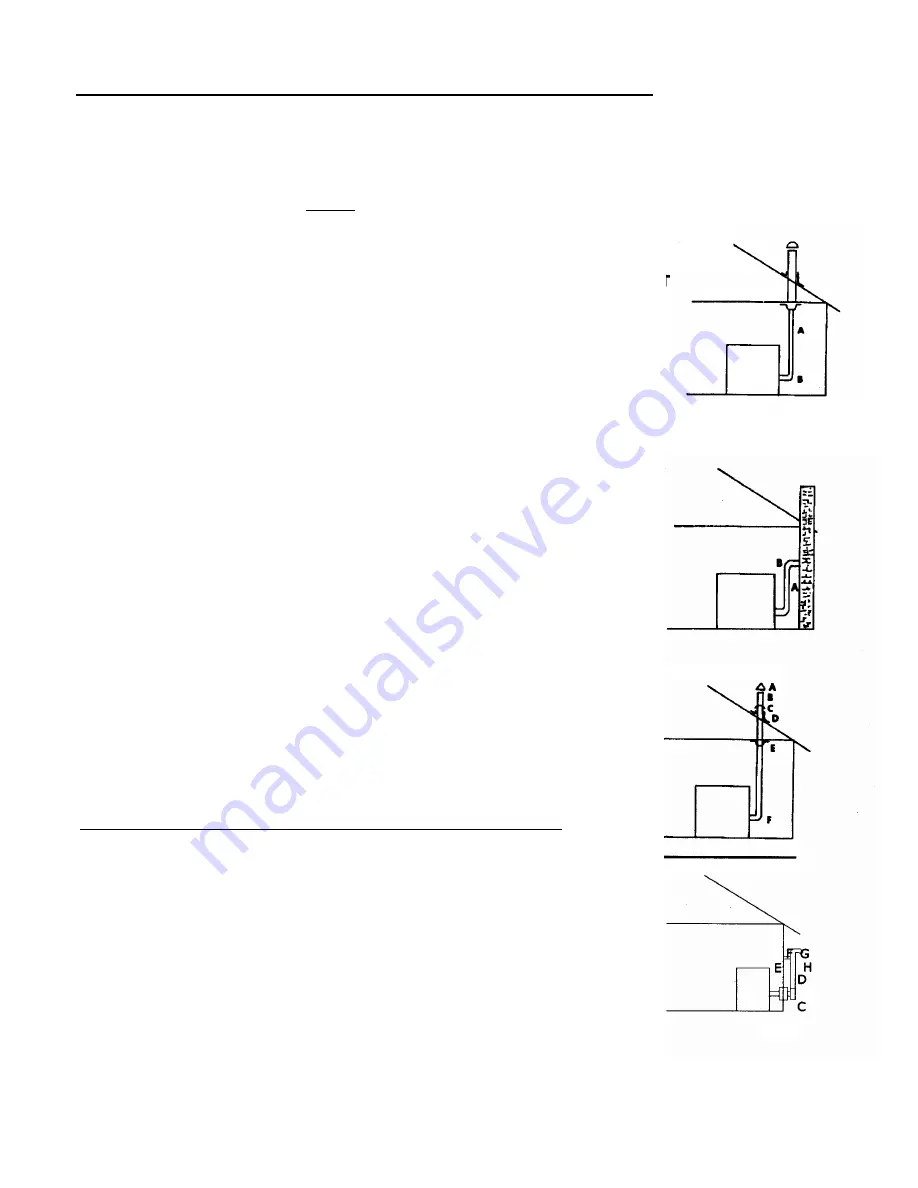

Chimney required for the Magnum 7500 Corn Furnace is 3 or 4" Class "L" (also known as PL vent). A starting

collar must be used to attach the venting system to the furnace. When connecting into a Class "A" or masonry

chimney an approved 3 or 4" liner MUST be used to prevent back drafting of the chimney.

EXISTING CLASS "A" CHIMNEY:

Run 3” or 4” Class "L" venting from the furnace connection to a positive

connection with the class "A" chimney. AN APPROVED 3” or 4" LINER MUST

BE USED IN CLASS "A" CHIMNEYS. Make sure each joint is firmly

locked in place. Make sure the attachment of Class "L" to the Class "A"

chimney is secure with sheet metal screws. Seal all joints with high- temperature silicone..

Class "L" venting should maintain a pitch on rise from the furnace to the chimney

of at least 1/4" per foot. .

A): "L" Vent venting 3”or 4" B): "L" Vent elbow 90°, adj. 3” or 4" or Tee

EXISTING MASONRY CHIMNEY:

Run 3”or 4" Class "L" venting from the

furnace connection to a positive connection with the masonry

chimney. Make sure each joint is firmly locked in place. Make sure

the penetration of the Class "L" venting into the masonry chimney

is sound and secured with high- temperature cement. Seal all joints with high-

temperature silicone. Class "L" venting should maintain a pitch on rise

from the furnace to the chimney of at least 1/4" per foot.

AN APPROVED 3”or 4" LINER MUST BE USED IN MASONRY CHIMNEYS.

Your new furnace is so efficient; an unlined chimney could remain cold and cause

a downward pressure creating poor burning, incomplete combustion or back draft.

A.)"L" Vent venting 3”or 4" B.)"L" Vent elbow, 90° adj. 3”or 4" or Tee

NEW VERTICAL INSTALLATIONS

: Install 3”or 4" Class "L" venting and

accessories according to manufacturers instructions and local codes

(3" clearance to combustibles). Run Class "L" venting all the way from the

furnace connection to point of termination. Make sure each joint is

firmly locked in place. Seal all joints with high temperature silicone.

Class "L" venting should maintain a pitch on rise from the furnace to

the chimney of at least 1/4" per foot.

A.) Vertical top 3” or 4" D.) Adj. flashing 3”or 4"

B.) "L" Vent pipe 3”or 4" E.) Fire stop spacer 3”or 4"

C.) Storm Collar 3”or 4" F.) "L" Vent 90° adj.3”or 4" clean out tee

HORIZONTAL/VERTICAL

VENTING:

If venting

the

Magnum 7500

Horizontally through an exterior wall,

a vertical

section needs to be

installed to

provide natural draft in the event of power failure.

Use only 3”or 4" Class

"L" venting all the way from the furnace connection

to

point of

termination.

Make sure each joint is firmly locked in place.

Seal all joints with high temp silicone. Max. horizontal run length - 4ft.;

Min.

vertical length - 5 ft.

A.) "L" Vent pipe 3”or 4" B.) Wall thimble 3”or 4" C.) "L" vent 3” or 4" cleanout "T"

D.) "L" Vent pipe 5ft E.) Wall Bracket F.) "L" vent 90° elbow ."

G

.) "L" vent Termination collar 3” or 4”

If installing the venting on the exterior of the home or shop, the venting must

be enclosed in an insulated chase to prevent condensation and creosoting.

DIRECT VENT HORIZONTAL TERMINATION IS NOT RECOMMENDED