Step 1

Step 5

Open the cover of the control box and connect two 3/8” polyflow

lines to the two push-in fittings on the valve inside the control box.

Plumb through the cord grips located on the right side of the

control box to the push-in fittings located on the top side of the

operator cylinders. Plumb the airlines from the control box to the

top of the operator cylinders. The top airline fitting on the control

box goes to the front cylinder (farthest from the jamb) and bottom

airline goes to the back cylinder (closest to the jamb). Tighten cord

grips on the right side of the control box when complete. (Figure 2)

Important!

Control boxes should be used with an inline

OLTXLGVHSDUDWRU

!! See

recommendations.

We recommended to keep the airlines as short

as possible to reduce internal condensation in the airlines

Step 6

0RXQW

the flow control kit to your wall.

It is recommended to

locate the flow control kit in an area away from the doorway

and direct spray.

Plumb 3/8”

airlines from the previously

installed push-in fitting on the bottom of the cylinders to the

push-in fittings located on the top of the flow controls.

Plumb the line from cylinder nearest the jamb to the close

and the

line farthest away from the jamb to open.

Plumb bottom of

flow control with a 12”

drain tube

Step 7

Tighten the flow control

YDOYHV

(clockwise) completely.

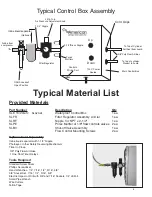

Figure 1

Filter/Regulator

Shut-off Valve Assembly

2-1/2” Nipple

Valve

Airlines

Cord Grips

Figure 2

Figure 3

Figure 4

Control Box Assembly & Installation

To

Cylinders

From

Compressor

Push-in Fittings

To Flow

Control

Install the two

3

orex mufflers

RU)ORZFRQWUROYDOYHV

to the top and bottom ports

on the left side of the control

box.

Hand tighten only.

Step 2

Install the filter regulator assembly onto the control box

using the 2½" brass nipple.

Insert through the middle hole

on the left side of the control box and tighten.

Use teflon

tape on threads.

(Figure 1)

Step 3

Install the shut-off valve assembly into the filter/regulator

using the 1-1/2”

QLSSOH

For optional inline

OLTXLGVHSDUDWRU

use additional 1-1/2”

nipple.

(Figure 1)

Step 4

Mount the control box to the wall or other surface at the desired location .

O

ptional Inline

D

ryer/

S

eparator

11