How the Flow Control Assembly Works

Attention!!!

Our control boxes are configured for momentary dry contact signaling only.

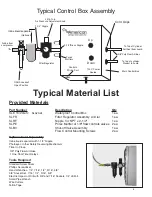

For easy tie-in to carwash and other equipment use the following components.

Signal from Equipment

Type of Component

24 VAC Pulse Current

24 VAC Relay, N/O Contact

110 VAC Pulse Current

110 VAC Relay, N/O Contact

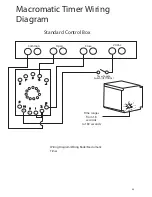

24 VAC Continuous Current

24 VAC One Shot Timer, N/O Contact

110 VAC Continuous Current

110 VAC One Shot Timer, N/O Contact

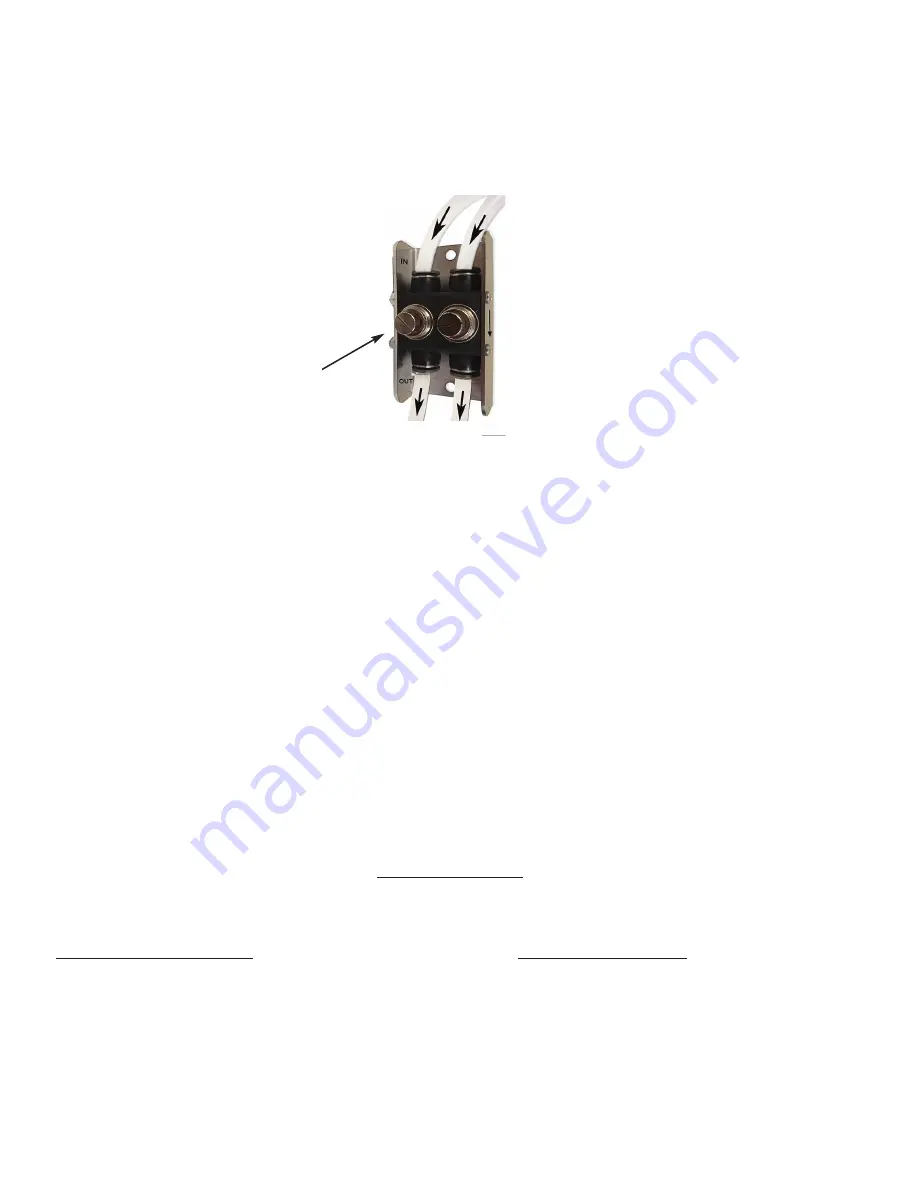

Flow Control

Adjustment

Flow Control

Adjustment

)URP%RWWRPRIF\OLQGHUV

The flow control valve meters the volume of air escaping from the bottom of the cylinder as the

pis-ton is being pushed downward.

Closing the valves will slow the travel speed of the door.

The

check

ball in each valve allows each cylinder to breath freely as the piston is draw up

mechanically by the

chain on the reverse cycle.

Caution!!

The Supralift operator is capable of opening and closing the door at very high speeds.

Recommended door travel speed is 1 to 1-1/2 feet per second.

( example:

10’

high door= 7

seconds)

Excessive door travel speed will increase the chances for malfunction of your door or

the operator to

occur which could result in injury or damage to persons or property.

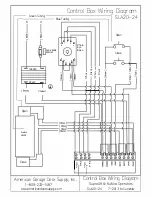

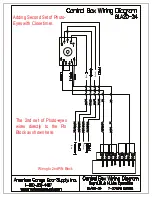

Step 5

Wire in loop detectors, pushbuttons, photoeyes

WLPHUV

and other controls or accessories as

required.

Plug in t

KH

r

photoeye amplifier.

Photoeye sockets are previously installed for your

FRQYHQLHQFH

If ordered with the control box, timer sockets will also be installed for your convenience.

For wiring information, please see wiring diagrams.

13