30 - FORM NO. 56041667

American-Lincoln Technology

7765 / 7760

MAIN BROOM LEVEL ADJUSTMENT

The main broom level is factory set and shouldn’t need adjustment, if the level gets out of adjustment and the

broom bristle contact pattern is not an even 2” to 3” (5 to 8 cm.) wide. Adjust the broom arm lift frame. The frame

is supported by two fl ange bearings. These bearings are located inside the broom doors. The carriage bolts on

the two end fl anges must be loosened. The frame can then be leveled and the bolts tightened.

HOW TO ADJUST MAIN BROOM WEAR PATTERN

When the bristles of the broom begin to wear out the following adjustments may be made to keep a 2-inch

(5-cm.) broom pattern.

1. Loosen the nut located in the engine compartment.

2. Set the broom lever to the “Sweep” position and adjust the lock nut to obtain a 2-inch (5 cm) broom

pattern. The lock nut will move the adjusting rod that adjusts the sweeping pattern of the broom for wear.

GENERAL MACHINE MAINTENANCE

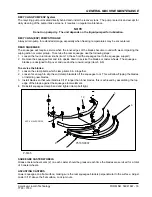

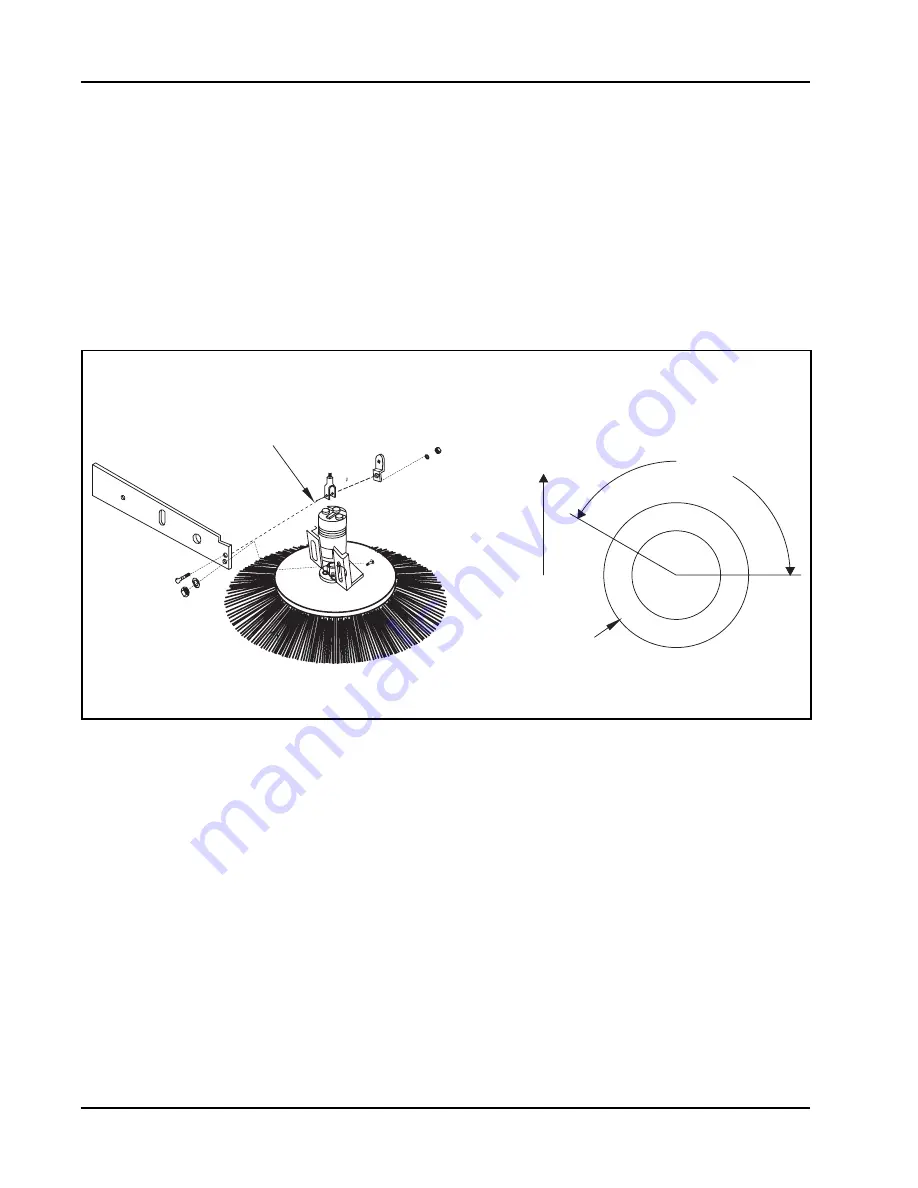

SIDE BROOM LEVEL ADJUSTMENT

As the side broom wears, loosen the two wear adjusting bolts and slide the broom-motor assembly into a position

so that the broom contacts the fl oor at a 3 degree angle when lowered as shown in Figure 29.

SIDE BROOM REPLACEMENT

Put the side broom lift control in the “UP” position. Remove the retaining screw in the bottom middle of the side

broom. Remove the side broom. Transfer the side broom fl ange spacer and screws to the replacement side

broom. Put the replacement side broom on the shaft. Put the retaining screw in position and tighten.

RAISE

OR

LOWER

FOR

WEAR

ADJUSTMENT

FORWARD

FLOOR

CONTACT

AREA

SIDE

BROOM

3

P-5117

FIGURE

29