American-Lincoln

®

1-35

SC7740

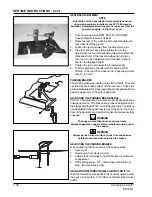

CHECKING THE SPARK PLUG GAP (at 400 hours)

1. Remove the carbon.

2. Measure the clearance with a feeler gauge.

3. If the clearance is outside the reference value, readjust it.

4. The factory specification for the spark plug gap is 0.039 to 0.043 in. (1.0 to 1.1 mm).

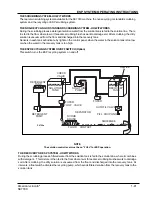

CLEANING/CHANGING THE FUEL FILTER

1. Stop the fuel from tank.

2. Replace the fuel filter cartridge with a new one every 400 hours of operation.

3. The fuel filter should be checked at every 100 hours of operation and cleaned if necessary.

CHECKING THE FUEL HOSES

1. Since the fuel hose (2) is made of rubber, it ages regardless of the period of service. Check fuel hoses every

100 hours of operation. Change the fuel hose together with the clamp every two years.

2. If the fuel hose and clamp are found to be damaged or deteriorate earlier than two years, then change.

3. After the fuel hose and the clamp have been changed, bleed the fuel system.

4. Check water hoses to see if they are properly fixed every 200 hours of operation or every six months,

whichever comes first.

5. If the clamp is loose, apply oil to the threads and retighten it securely.

6. The water hose is made of rubber and tends to age. It must be changed every two years. Also change the

clamp and tighten securely.

WARNING

Stop the engine when attempting the check or change the fuel hose.

VALVE CLEARANCE (Check every 800 hours of use)

1.

Loosen the lock nut and the adjusting screw on the rocker arm.

2.

Turn the adjusting screw to adjust the valve clearance at the top dead center (T.D.C.) during the compres-

sion stroke of the piston. (To get the T.D.C., find piston’s “TC” mark on the flywheel and align it to

punchmark line on the rear end plate.)

3.

Tighten the lock nuts and check the valve clearance again after several turns of the flywheel.

4.

The factory specification for valve clearance is 0.0057 to 0.0072 inches (0.145 to 0.185 mm) with engine

cold.

AIR CLEANER

The air cleaner on this engine is a dry type. Never apply oil.

1.

Open the evacuator valve once a week under ordinary circumstances (daily when used in dusty conditions).

This will get rid of any large dust and dirt particles.

2.

Wipe the inside of the air cleaner with a cloth if dirty or wet.

3.

Avoid touching the element except when cleaning.

4.

When dry dust adheres to the element, blow compressed air from the inside while turningthe element.

Pressure of compressed air must be under 686kPa (7kgf/cm2, 99 psi). Maintain a reasonable distance

between the nozzle and filter.

5.

When carbon or oil adheres to the element, soak in detergent for 15 minutes then wash several times in

water, rinse with clean water, and dry naturally.

6.

After element is fully dried, check inside it (with a strong light source) for damage. Reinstall (or replace if

damaged), making sure the wing bolt is tightened.

7.

Replace element every year or every 6 cleanings, whichever comes first.

GENERAL MACHINE MAINTENANCE - Cont.