American-Lincoln

®

1-39

SC7740

LP CHECKLIST

This checklist can be performed quickly and should be done before every use. Be sure to make all necessary

checks as listed on the Maintenance Chart discussed earlier.

1.

Check connections for leaks.

2.

Open the LP storage tank valve.

3.

Check the regulator. Momentarily press the fuel primer on the regulator cover to bleed air out of the system.

4.

Start the machine’s engine.

LP FUEL TANKS

Standard D.O.T. LP fuel tank sizes have 14, 20, 33.5, and 43.5 pound capacities. The liquid volume permitted in

these containers is less than the total volume of the cylinder. This provides for expansion of the LP fuel in the case

of a temperature increase above the normal amount. Excessive heat may cause the fuel to expand too much,

causing the safety relief valve to vent some LP fuel, relieving internal tank pressure.

Each tank is marked showing the type of construction (liquid or vapor), the manufacturer, the date of manufacture,

the capacity, the weight, and the date of requalification. D.O.T. fuel tanks must be requalified (checked) periodi-

cally. This requalification must be recorded and maintained for the life of the container.

LP fuel tanks are equipped with the following approved valves and fittings:

* Safety Relief Valve - This is a spring-loaded valve that relieves excessive pressures which may develop in the

tank due to unusual conditions.

* Liquid Service Valve - Liquid is withdrawn from the tank through this valve. The LP tank may be filled through

this valve if the tank is not equipped with a filter valve.

* Excessive Flow Valve - This valve is part of the liquid service valve. It is mounted inside the tank and prevents

LP fuel from leaving the LP tank in the event of accidental breakage of external fittings or hoses.

* Filler Valve - This valve is optional. If this valve is not present, the tank is filled through the service valve.

* Liquid Level Gauge - This gauge is optional.

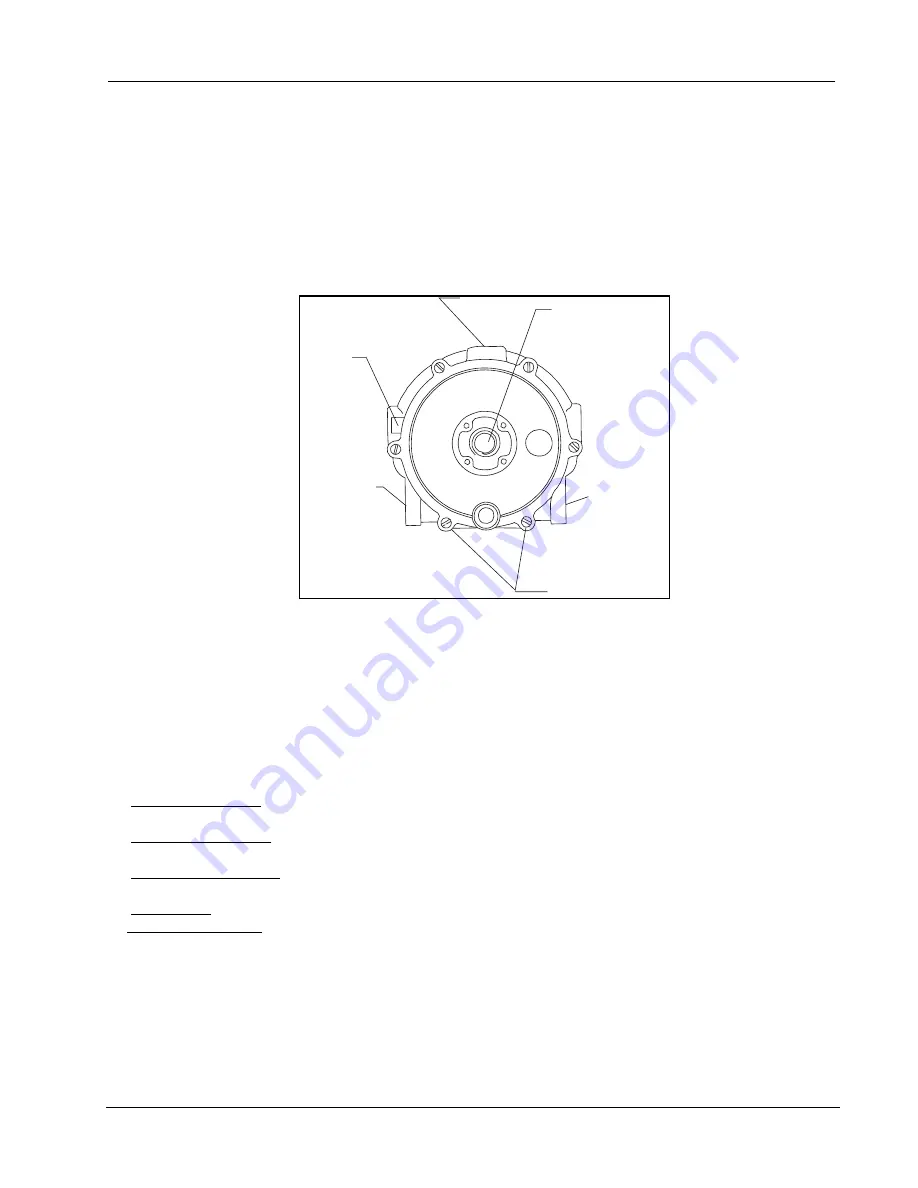

LPG

INLET

HAND

PRIMER

PIN

PLUG

VAPOR

OUTLET

P-4563A

WATER

MOUNTING HOLES

LP TANK COMPONENTS