18-CD24D1-2

19

Installer’s Guide

ELECTRICAL CONNECTIONS

Make wiring connections to the unit as indicated on en-

closed wiring diagram. As with all gas appliances using

electrical power, this Furnace shall be connected into a

permanently live electric circuit. It is recommended

that Furnace be provided with a separate “circuit pro-

tection device” electric circuit. The Furnace must be

electrically grounded in accordance with local codes or

in the absence of local codes with the National Electri-

cal Code, ANSI/ NFPA 70 or CSA C22.1 Electrical Code,

if an external electrical source is utilized.

The inte-

grated Furnace control is polarity sensitive

.

The

hot leg of the 120V power supply must be connected to

the black power lead as indicated on the wiring dia-

gram. Provision for hooking up a humidifier is provided

on the integrated control.

Refer to the SERVICE FACTS literature and unit wiring

diagram attached to furnace.

GAS PIPING

▲

WARNING

!

DO NOT USE SEMI-RIGID METALLIC GAS CONNEC-

TORS (FLEXIBLE GAS LINES) WITHIN THE FURNACE

CABINET. FAILURE TO FOLLOW THIS WARNING

COULD RESULT IN PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

The following warning complies with State of California law, Proposition 65.

Hazardous Gases!

Exposure to fuel substances or by-products of

incomplete fuel combustion is believed by the state of

California to cause cancer, birth defects, or other

reproductive harm.

▲

WARNING

!

▲

CAUTION

!

Use a backup wrench on the Gas Valve when installing

gas piping to prevent damage to the Gas Valve and

Manifold Assembly.

The installation of piping shall be in accordance with

piping codes and the regulations of the local gas com-

pany. Pipe joint compound must be resistant to the

chemical reaction with liquefied petroleum gases.

Refer to piping Table 6, for delivery sizes. Connect gas

supply to the unit, using a ground joint union and a

manual shut-off Valve as shown in Figures 14 and 15.

National codes require a condensation drip leg to be in-

stalled ahead of the controls as shown in Figures 14 and

15.

The Furnace and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5 kPa).

▲

WARNING

!

EXPLOSION HAZARD!

PROPANE GAS IS HEAVIER THAN AIR AND MAY

COLLECT IN ANY LOW AREAS OR CONFINED

SPACES. IF THE GAS FURNACE IS INSTALLED IN A

BASEMENT, AN EXCAVATED AREA OR A CONFINED

SPACE, IT IS STRONGLY RECOMMENDED TO CON-

TACT A GAS SUPPLIER TO INSTALL A GAS DETECT-

ING WARNING DEVICE IN CASE OF A GAS LEAK

.

NOTE: The manufacturer of your furnace does not

test any detectors and makes no representations re-

garding any brand or type of detector.

▲

WARNING

!

EXPLOSION HAZARD!

ODORANT FADE MAY MAKE THE GAS UNDETECT-

ABLE EXCEPT WITH A WARNING DEVICE. IF THE

GAS FURNACE IS INSTALLED IN A BASEMENT, AN

EXCAVATED AREA OR A CONFINED SPACE, IT IS

STRONGLY RECOMMENDED TO CONTACT A GAS

SUPPLIER TO INSTALL A GAS DETECTING WARN-

ING DEVICE IN CASE OF A GAS LEAK.

NOTE: The manufacturer of your furnace does NOT

test any detectors and makes no representations re-

garding any brand or type of detector.

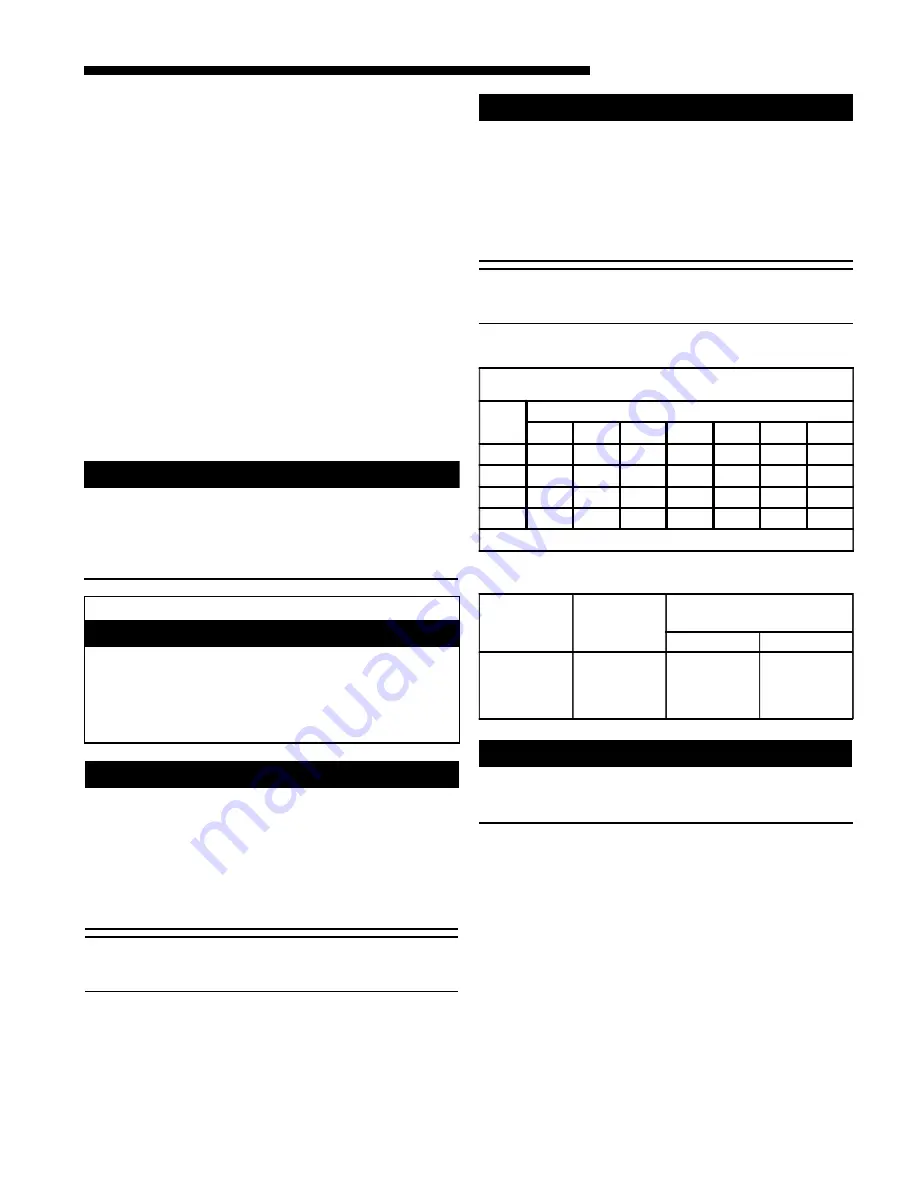

TABLE 6

NATURAL GAS ONLY

TABLE OF CUBIC FEET PER HOUR OF GAS

FOR VARIOUS PIPE SIZES AND LENGTHS

PIPE

SIZE

LENGTH OF PIPE

10

20

30

40

50

60

70

1/2

132

92

73

63

56

50

46

3/4

278

190

152

130

115

105

96

1

520

350

285

245

215

195

180

1-1/4

1050

730

590

520

440

400

370

This table is based on pressure drop of 0.3 inch W.C. and 0.6 SP.GR. gas

TABLE 7

ORIFICE SIZES

INPUT

RATING

BTUH

NUMBER

OF

BURNERS

MAIN BURNER ORIFICE

DRILL SIZE

NAT. GAS

LP GAS

60,000

80,000

100,000

120,000

3

4

5

6

45

45

45

45

56

56

56

56