18-CD24D1-2

25

Installer’s Guide

Heating:

The Integrated Furnace Control (IFC) con-

trols the Variable Speed Indoor Blower. The blower

“on” time is fixed at 45 seconds after ignition. The

FAN-OFF period is field selectable by dip switches #1

and #2 located on the Integrated Furnace Control be-

tween the 5-pin and 9-pin wire connectors. The delay

may be set at 60, 100, 140, or 180 seconds. The factory

setting is 100 seconds (See unit wiring diagram).

Cooling:

The fan delay-off period is set by dip switches

on the Integrated Furnace Control. The options for

cooling delay off is field selectable by dip switches #5

and #6.

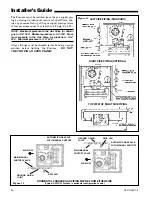

The following table and graph explain the delay-off set-

tings:

TABLE 12 FAN OFF - DELAY OPTIONS

SWITCH SETTINGS

SELECTION

NOMINAL

AIRFLOW

5 - OFF

6 - OFF

NONE

SAME

5 - ON

6 - OFF

1.5 MINUTES

100% *

5 - OFF

6 - ON

3 MINUTES

50%

5 - ON

6 - ON

Enhanced

Mode**

50 - 100%

This unit is equipped with a blower door switch which

cuts power to the blower and Gas Valve causing shut-

down when the door is removed. Operation with the

door removed or ajar can permit the escape of danger-

ous fumes. All panels must be securely closed at all

times for safe operation of the Furnace.

* - This setting is equivalent to BAY24X045 relay ben-

efit.

** - This selection provides ENHANCED MODE, which

is a ramping up and ramping down of the blower

speed to provide improved comfort, quietness, and

potential energy savings. See Wiring Diagram

notes on the unit or in the Service Facts for com-

plete wiring setup for ENHANCED MODE. The

graph which follows, shows the ramping process.

See Wiring Diagram on the unit or in the Service

Facts for complete wiring setup for Enhanced

Mode.

AIRFLOW ADJUSTMENT

▲

WARNING

!

Disconnect power to the unit before removing the

blower door. Allow a minimum of 15 seconds for IFC

power supply to discharge to 0 volts.

Failure to follow this warning could result in property

damage, personal injury or death.

▲

WARNING

!

Operation with the door removed or ajar can permit the

escape of dangerous fumes. All panels must be se-

curely closed at all times for safe operation of the Fur-

nace.

Failure to follow this warning could result in property

damage, personal injury or death.

Check inlet and outlet air temperatures to make sure

they are within the ranges specified on the Furnace rat-

ing nameplate. If the airflow needs to be increased or

decreased, see the Service Facts for information on

changing the speed of the blower motor.

1

minute

3

minutes

7.5

minutes

OFF

50%

50%

80%

Dehumidify

Efficiency

Fast Cooling

100% if necessary

OFF

This unit is equipped with a blower door switch which

cuts power to the blower and Gas Valve causing shut-

down when the door is removed.

ROOM AIR COMFORT CONTROL

HEAT ANTICIPATOR ADJUSTMENT

Set the Comfort Control heat anticipator according to

the current flow measured, or the settings found in the

notes on the Furnace wiring diagram (found in the SER-

VICE FACTS or inside the furnace casing).

▲

WARNING

!

Should overheating occur, or the gas supply fail to

shut off, shut off the Gas Valve to the unit before shut-

ting off the electrical supply.

Failure to follow this warning could result in property

damage, personal injury, or death.

INSTRUCTIONS TO THE OWNERS

In the event that electrical, fuel, or mechanical

failures occur, the owner should immediately

turn the gas supply off at the manual Gas Valve,

located in the burner compartment. Also turn off

electrical power to the Furnace and contact a

qualified service technician.

BURNER BOX TEMPERATURE LIMIT DEVICE

All models are equipped with a manual reset tempera-

ture limit located on the Burner Box. In case of exces-

sive temperature, the limit will open and cause the cir-

cuit to open which shuts off all flow of gas.