18-CD24D1-2

7

Installer’s Guide

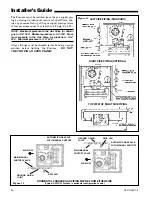

HORIZONTAL INSTALLATION

The coil and furnace must be fully supported when used

in the horizontal position.

INSTALLATION INSTRUCTIONS

▲

CAUTION

!

Bottom panel for furnace to remain in place until unit

reaches final installation location. If bottom panel is re-

moved before installation the collection cell and field

charger must also be removed to protect installation

personnel.

▲

CAUTION

!

Remove the COLLECTION CELL and remove and dis-

card the cardboard over the cell.

NOTE: No sheetmetal screws may be used from 0-4"

from the bottom of the unit. Screws will interfere with

the Air Cleaner. See Figure 4.

REMOVING THE BOTTOM PLATE

a.

Once the furnace is in place, remove the two screws

located at the front bottom corners of the Furnace.

b.

Lean the furnace back slightly and remove the bot-

tom panel.

c.

Replace the two screws removed in step a.

REMOVING THE COLLECTION CELL AND FIELD

CHARGER

When COLLECTION CELLS and FIELD CHARGER

must be removed, follow the steps below.

a.

Remove the lower furnace door.

b.

Remove the four screws holding the inner blower

panel and remove panel. Set aside in a safe place

until the unit is set in place and ready to start up.

c.

Remove the COLLECTION CELL by sliding for-

ward. Remove the cardboard from the COLLEC-

TION CELL and discard. Set aside in a safe place

until the unit is set in place and ready to start up.

d.

Disconnect the Green return wire and the Red high

voltage wire. Twist and pull the connector on the

Red wire to release.

e.

Remove the two hold down screws on the bottom of

the FIELD CHARGER and retain.

f.

Remove the Field Charger. Set aside in a safe

place until the unit is set in place and ready to start

up.

g.

Set furnace in place. Repeat step a-g in reverse or-

der. Do Not put cardboard back in Furnace. Inner

blower door MUST be put back into place.

UP

FL

OW

FU

RN

AC

E

CASED

COIL

SCREWS

(BOTH SIDES)

STANDOFFS

(BOTH SIDES)

STANDOFFS (4)

DRILL SCREWS (4)

FOR VERTICAL

Figure 2

UPFLOW INSTALLATION

Standoffs and screws (See Figure 2) are included with

the cased coils for attachment to the Furnace. There

are clearance alignment holes near the bottom of the

coil wrapper. Drill screws are used to engage the Fur-

nace top flanges. The standoff is inserted into the cabi-

net alignment hole. The drill screws are inserted

through the standoffs then screwed into the Furnace

flange. The coil is always placed downstream of the Fur-

nace airflow. The above instructions apply only if the

coil is on top of an upflow Furnace.

The cased coil is secured to the Furnace and both the

Furnace and the cased coil must be properly supported.

The brackets mount using the rear screws on the coil

case and use the screws provided to secure the bracket

to the Furnace. The remaining bracket is placed as

close to center as possible (horizontally) between the

coil case front and the upflow Furnace, converted to

horizontal, aligns and attaches to the TXC coil. How-

ever, the coil requires additional support.

The horizontal Furnace installation in an attic should

be on a service platform large enough to allow for

proper clearances on all sides and service access to the

front of the Furnace (See Figure 3 & Clearance Table

1). Line contact is only permissible between lines

formed by intersections of the top and two sides of the

furnace casing and building joists, studs, or framing.

IMPORTANT:

The 2/4TXC cased coil must be placed downstream of the

furnace. In horizontal installations, the apex of the coil

may point either toward or away from the furnace. See

the 2/4TXC coil Installer's Guide for more details.