C L

TO RAISE

WATER

LEVEL

FLAPPER

ASSEMBLY

TO LOWER

WATER

LEVEL

TRIP

LEVER

FLUSH

VALVE

WATER

INLET

OVERFLOW

TUBE

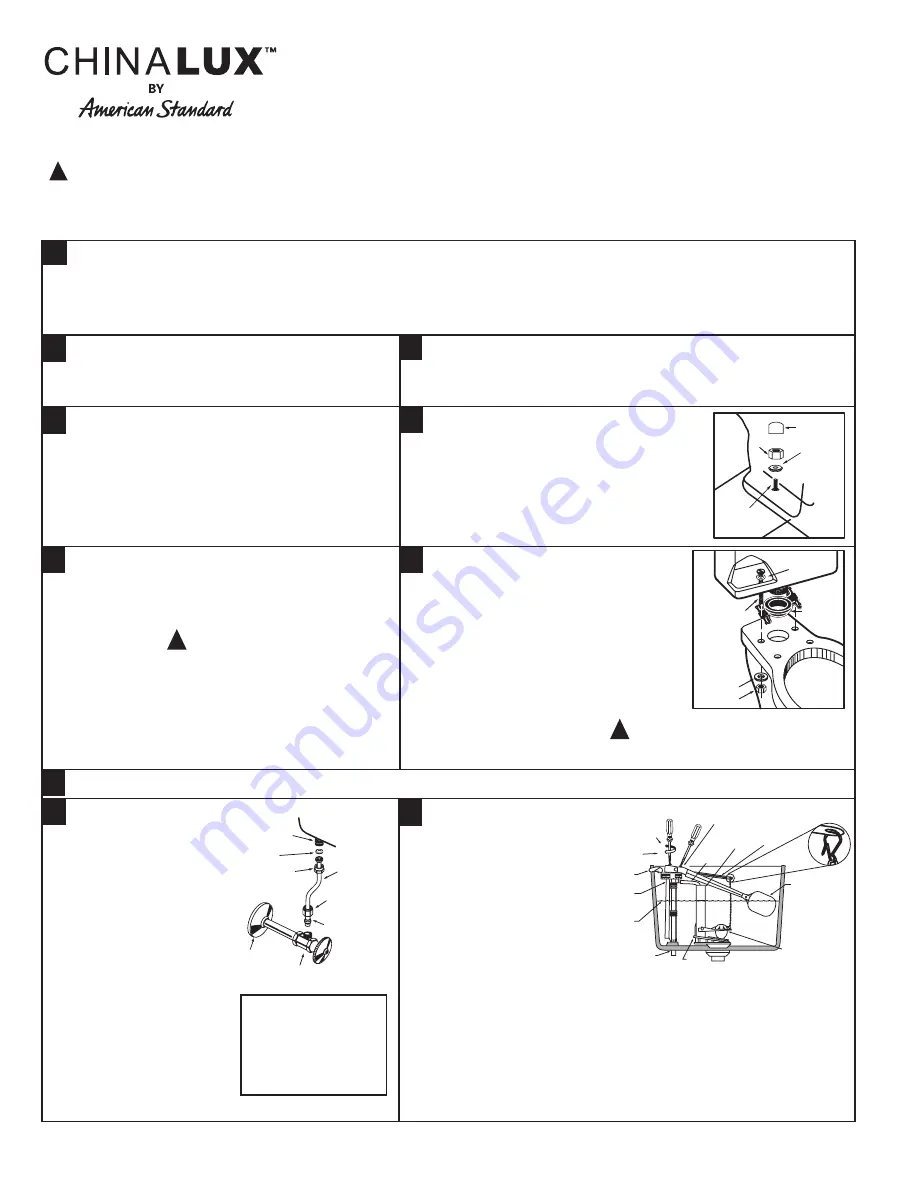

FIG. 10A

WATER

LINE

LEVEL

+

WATER

CONTROL

ASSEMBLY

-

FLOW RATE

ADJUSTMENT

REFILL

TUBE

LIFT

ROD

FLOAT

BALL

RECOMMENDED TOOLS AND MATERIALS

Putty Knife

Regular Screwdriver

Adjustable Wrench

Wax Ring/Gasket

Flexible Supply Tube

Tape Measure

Closet Bolts

Hacksaw

Sealant

Carpenters Level

Seat

1

REMOVE OLD TOILET

a. Close toilet supply valve and flush tank completely. Towel or sponge remaining water from tank and bowl.

b. Disconnect and remove supply line. NOTE:

If replacing valve, first shut off main water supply!

c. Remove old mounting hardware, remove toilet and plug floor waste opening to prevent escaping sewer gases.

d. Remove closet bolts from flange and clean away old wax, putty, etc. from base area.

NOTE:

Mounting surface must be clean and level

before

new toilet is installed!

SAVE FOR FUTURE USE

3

2

ROUGHING-IN DIMENSIONS:

NOTE:

Distance from wall to closet flange centerline

must be as listed below:

For 120012 Tanks: Rough-in distance is 305mm (12")

7301311-100 Rev.A

CAUTION: PRODUCT IS FRAGILE. TO AVOID BREAKAGE AND POSSIBLE INJURY HANDLE WITH CARE!

NOTE:

Pictures may not exactly define contour of china and components.

!

ChinaLux 1000 EL

ChinaLux 1000 RF

POSITION TOILET ON FLANGE

a. Unplug floor waste opening and install toilet on

closet flange so bolts project through

mounting holes.

b. Loosely install retainer washers and nuts. Side of

washers marked “THIS SIDE UP”

must

face up!

a. Position toilet squarely to wall and, with a rocking

motion, press bowl down fully on wax ring and flange.

Alternately tighten nuts until toilet is firmly seated

on floor.

CAUTION:

DO NOT OVERTIGHTEN NUTS

OR BASE MAY BE DAMAGED!

b. Install caps on washers. (If necessary, cut bolt height

to size before installing caps.)

c. Smooth off the bead of sealant around base.

Remove excess sealant.

a. Install large rubber gasket over threaded

outlet on bottom of tank and lower tank

onto bowl so that tapered end of gasket

fits evenly into bowl water inlet opening.

b. Insert tank mounting bolts and rubber

washers from inside tank, through

mounting holes and gasket, and secure

with metal washers and nuts.

c. With tank parallel to wall, alternately

tighten nuts until tank is

snugged down evenly

against bowl surface.

INSTALL TOILET SEAT

Install toilet seat in accordance with manufacturer’s directions.

CLOSET

BOLT

NUT

TAPERED

WASHER

!

INSTALL WAX SEAL

Invert toilet on floor (cushion to prevent damage),

and install wax ring evenly around waste flange

(horn), with tapered end of ring facing toilet. Apply

a thin bead of sealant around base flange.

!

CAUTION:

DO NOT OVERTIGHTEN NUTS MORE

THAN REQUIRED FOR A SNUG FIT!

TANK MTG.

BOLTS

NUT

WASHER

RUBBER

GASKET

RUBBER

WASHER

ADJUSTMENTS

a. Flush tank and check that

tank fills and shuts off within

30 to 60 seconds, and tank

water level is set as

specified on tank rear wall.

b. To adjust water level:

turn water level adjustment

screw counterclockwise to

raise level; turn adjustment

screw clockwise to lower level.

c. To adjust flow rate (tank fill time):

turn flow rate adjustment screw

clockwise to decrease flow rate (increase fill time); turn adjustment screw

counterclockwise to increase flow rate (decrease fill time).

d. Carefully position tank cover on tank.

e. The flush valve float has been factory set and does not require adjustments.

Repositioning of the float will change the amount of water used which may

effect the toilet's performance.

f. If bowl fails to siphon, an adjustment may be required with the lift chain. Simply

remove the chain from the retainment clip (see Fig. 10) and take up slack on

the chain, and reinsert on lift rod. Make sure the chain is not too taught.

a. Connect water supply line

between shutoff valve and

tank water inlet fitting. Tighten

COUPLING NUT 1/4 turn

beyond hand tight. Check

that refill tube is inserted into

overflow tube.

b. Turn on supply valve and

allow tank to fill until float

rises to shutoff position.

c. Check for leakage at fittings,

tighten or correct as needed.

d. Do not use plumber's putty to

seal these fittings.

TANK

COUPLING NUT

FLEXIBLE

SUPPLY

WATER INLET

COMPRESSION

COLLAR

WASHER

VALVE NUT

TRIM PLATE

VALVE

CAUTION:

Overtightening of

COUPLING NUT could

result in breakage and

potential flooding.

INSTALL CLOSET BOLTS

Install closet bolts in flange channel, turn 90°, and slide into

place 6" (152 mm) apart and parallel to wall.

INSTALLATION INSTRUCTIONS

CARE AND MAINTENANCE

To ensure this product is installed properly, please read these instructions carefully before you begin.

Certain installations may require professional help.) Also be sure your installation conforms to local codes.

BOLT

CAP

10

9

8

7

6

5

4

CONNECT WATER SUPPLY

INSTALL TANK

INSTALL TOILET