Page 6

Pub. No. 32-5034-02

The problem solver.

A furnace is not a household appliance. It is complex and

requires professional maintenance and repair.

That’s why attempts at “do-it-yourself” repairs on an in-

warranty unit may void the remainder of your warranty.

Other than performing the simple maintenance recom-

mended in this manual, you should not attempt to make

any adjustments to your furnace. Your dealer will be able

to take care of any questions or problems you may have. A

periodic inspection of your furnace should be made by a

qualified service agency at the start of each heating season.

Keep your furnace looking like new for years.

Clean the enamel finish of your furnace with ordinary soap

and water. For stubborn grease spots, use a household

detergent. Lacquer thinner or other synthetic solvents may

damage the finish.

Problem

Possible Trouble

Possible Remedy

No Heating - Blower

1.

Thermostat set incorrectly.

1.

Adjust thermostat See operating

Does not operate

instructions

2.

Blown fuse or tripped circuit breaker.

2.

Replace or reset protective device

or call for servicer.

3.

Defective component.

3.

Most controls are automatic and will

recycle. If your unit still does not

operate call for servicer.

4.

Burner does not ignite.

4.

Call servicer.

5.

Main gas line turned off.

5.

Have gas company check.

6.

Blower door removed or ajar.

6.

Close door securely to restore power

to blower and gas valve.

7.

Lockout

7.

Turn power on-off-on-off twice

in 30 secs.

Insufficient Heating -

1.

Dirty air filters.

1.

Clean or replace filters.

Blower operates

continuously

2.

Blocked supply or

2.

Make sure registers are open and

return registers.

No obstacles blocking off the air.

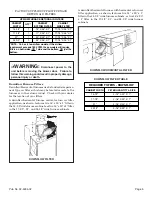

No Heat - Vent motor

Restricted or plugged furnace

1. Remove drain clamps to condensate

is running

condensate drain.

trap and drain pan outlet

2.

Flush or clear drain blockage.

3.

Reinstall clamps.

Unusual Noise

Call your servicer

Save time and money. Before calling for service, check the following:

CAUTION:

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dan-

gerous operation.

Verify proper operation after servicing.

WARNING:

Do not touch igniter. It is extremely hot. Failure to

follow this warning could result in severe burns, other

injury, property damage, or death.

WARNING

:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the installation and operation instruc-

tions for the venting system's operation could result in

carbon monoxide poisoning or death.