Pub. No. 32-5034-02

Page 7

Maintenance information.

Never stop the cooling system by shutting off the

main power.

If the main power to your air conditioner is ever discon-

nected for more than three hours, turn off the thermostat.

Then wait for at least three more hours after the power has

been restored before turning the thermostat back on.

Failure to follow this procedure could result in damage to

your air conditioning system.

1. GENERAL INSPECTION - Examine the furnace instal-

lation for the following items:

a. All flue product carrying areas external to the fur-

nace (i.e. chimney, vent connector) are clear and free of

obstruction.

b. The vent connector is in place, slopes upward and is

physically sound without holes or excessive corrosion.

c. The return air duct connection(s) is physically sound,

is sealed to the furnace and terminates outside the

space containing the furnace.

d. The physical support of the furnace should be sound

without sagging, cracks, gaps, etc., around the base so

as to provide a seal between the support and the base.

e. There are no obvious signs of deterioration of the

furnace.

2. BLOWERS - The blower size and speed determine the

air volume delivered by the furnace. The blower motor

bearings are factory lubricated and under normal operat-

ing conditions usually do not require servicing. Annual

cleaning of the blower wheel and housing is recommended

for maximum air output, and this must be performed only

by a qualified servicer or service agency.

3. IGNITER - This unit has a special hot surface direct

ignition device that automatically lights the burners. Please

note that it is very fragile and should be handled with care.

CAUTION: Do not touch igniter. It is extremely hot.

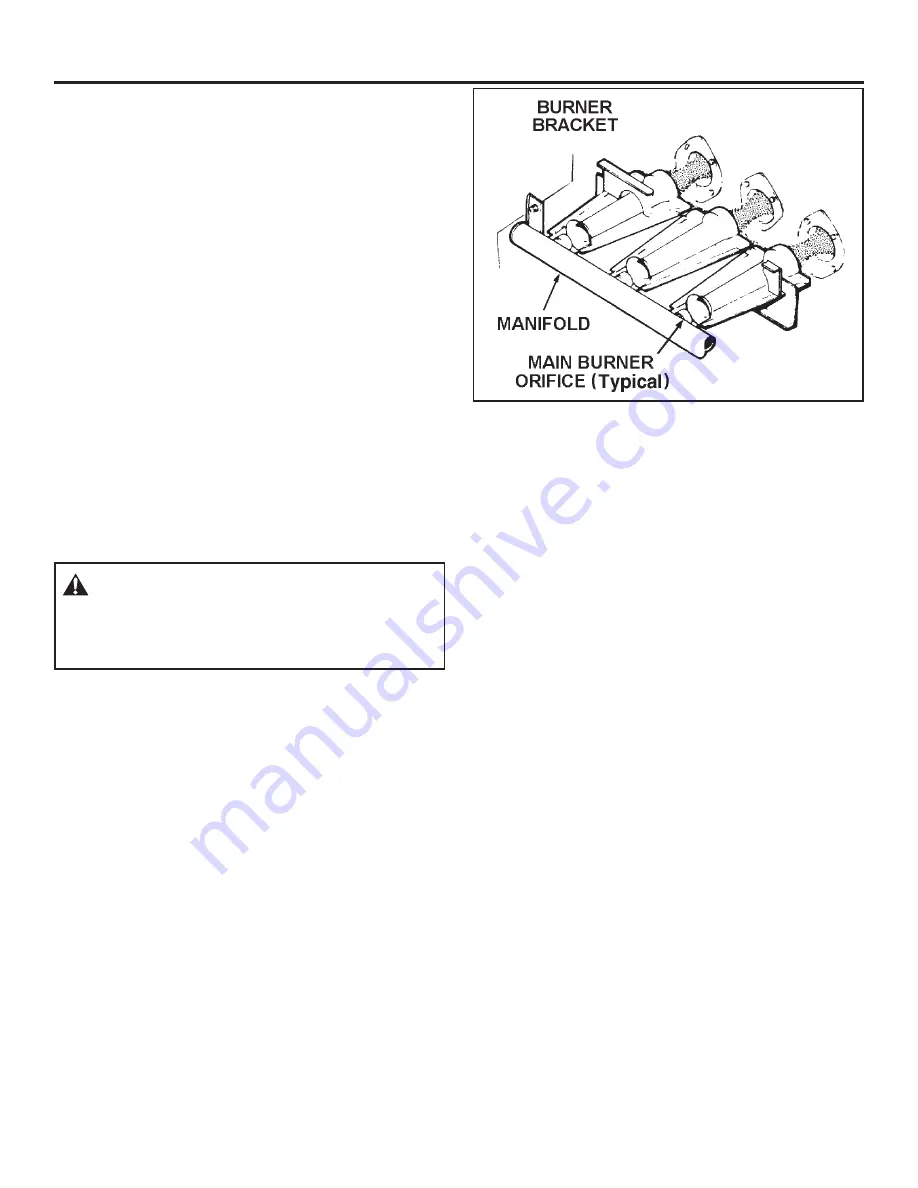

4. BURNER - Gas burners do not normally require sched-

uled servicing, however, accumulation of foreign material

may cause a yellowing flame or delayed ignition. Either

condition indicates that a service call is required. For best

operation, burners must be cleaned annually using brushes

and vacuum cleaner.

Turn off gas and electric power supply. To clean burners,

remove top burner bracket and lift burner from orifice.

NOTE: Be careful not to break igniter when remov-

ing burners.

Clean burners with brush and/or vacuum

cleaner. Reassemble parts by reversal of the above proce-

dure.

NOTE: On LP (propane) units, some light yellow tipping of

the outer mantle is normal. Inner mantle should be bright

blue.

Natural gas units should not have any yellow tipped

flames. This condition indicates that a service call is

required. For best operation, burners must be cleaned

annually using brushes and vacuum cleaner.

NOTE: On LP (propane) units, due to variations in BTU

content and altitude, servicing may be required at shorter

intervals.

5. HEAT EXCHANGER / FLUE PIPE - These items must

be inspected for signs of corrosion, and/or deterioration at

the beginning of each heating season by a qualified service

technician and cleaned annually for best operation.

6. CIRCUIT PROTECTION - If blower or gas valve fail to

operate, the cause could be the circuit breaker or a loose or

blown fuse. Replace fuse or reset circuit breaker.

7. OPERATION - Your warm air furnace should not be

operated in a corrosive atmosphere. Paint solvents, clean-

ing chemicals, spray propellants, and bleaches should not

be used in the vicinity of the furnace during normal

operation.

8. COOLING COIL CONDENSATE DRAIN - If you have

a cooling coil installed with your furnace, condensate

drains should be checked and cleaned periodically to as-

sure that condensate can drain freely from coil to drain. If

condensate cannot drain freely water damage could occur.

9. AIR CIRCULATION - To ensure increased comfort,

blower on this unit may be operated continuously for both

heating and cooling. This will result in constantly filtered

air and aid in maintaining more even temperatures by

avoiding temperature stratification throughout the condi-

tioned area. To accomplish constant air circulation, set

your thermostat fan switch to "ON".

WARNING:

Do not touch igniter. It is extremely hot. Failure to

follow this warning could result in severe burns.