Pub. No. 32-5034-02

Page 9

5. Turn gas cock knob counterclockwise to “ON” marker.

6. Replace control access panel.

7. Turn on main electrical supply and set thermostat to desired

setting. Combustion blower will start and ignition device will

start to heat up. After approximately 15 seconds main gas valve

will open and burners will ignite.

8. When thermostat is satisfied, main burners will extinguish.

9. If main burners fail to ignite, lower thermostat setting or

disconnect electrical supply, wait 5 minutes, raise thermostat

setting above indicated temperature.

10. If furnace will not light, turn “OFF” all gas and electricity to

unit and call servicer or gas supplier.

For complete shutdown.

Turn gas cock knob on main gas valve to “OFF” position. Discon-

nect electrical supply to unit.

CAUTION: If this is done during the cold weather months,

provisions must be taken to prevent freeze-up of all water pipes

and water receptacles.

Whenever your house is to be vacant, arrange to have someone

inspect your house for proper temperature. If your furnace

should fail to operate, damage could result, such as frozen water

pipes.

Safety cutoff device (thermal limit).

All models are equipped with a fusible link behind gas valve.

In case of main gas valve malfunction and consequent

overheating, link will open and close off flow of all gas. See

instruction label on front panel of heat exchanger.

Lighting instructions.

Your furnace is equipped with a hot surface direct ignition

device.

WARNING.

Do not attempt to manually light the furnace.

1. Please read all safety information in this book before operating

furnace.

2. Set thermostat to lowest setting. Turn off all electric power to

furnace.

3. Remove control access panel.

4. Turn gas cock knob on main gas valve with unit clockwise to

“OFF” position. If external gas cock is used, turn to “OFF”

position. Allow 5 minutes for any gas within the unit to escape.

LP gas being heavier than air may require forced ventilation. If

you smell gas STOP! Follow the “What To Do If You Smell Gas”

instructions on the front cover of this book. If you don’t smell gas,

go to next step.

To light furnace.

Your furnace may have a "Knob Switch" or a "Toggle Switch" to turn the gas ON or OFF.

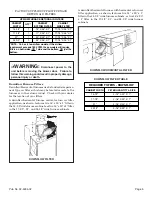

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in

serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for the

detection of leaks to check all connections. A fire or

explosion may result causing property damage, personal

injury, or loss of life.