12

18-CE12D1-1D-EN

flue loss less than 17 percent. These conditions require

special venting systems, which must be gas tight and

water tight. These Category IV Direct Vent furnaces are

approved for installation in Manufactured/ Mobile

housing when used with BAYMFGH200B.

A manufactured (mobile) home installation must

conform with the

Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280,

or when

this Standard is not applicable, the

Standard for

Manufactured Home Installations (Manufactured Home

Sites, Communities and Set-Ups), ANSI/NCS A225.1.

and/or

MH Series Mobile Homes, CAN/CSA-Z240.

Locations and Clearances

The location of the furnace is normally selected by the

architect, the builder, or the installer. However, before

the furnace is moved into place, be sure to consider the

following requirements:

1. Is the location selected as near the chimney or vent

and as centralized for heat distribution as practical?

2. Do all clearances between the furnace and

enclosure equal or exceed the minimums stated in

Clearance Table below?

Minimum clearance to combustible materials

Closet

Sides

0 in.

Back

1 in.

Top

1 in.

Front

0 in.

Bottom

0 in.

Flue

0 in.

24 in. minimum front clearance recommended for service

Horizontal Closet and Alcove

Right Side

0 in.

Left Side

0 in.

Back

1 in.

Top

1 in.

Bottom

0 in.

Flue

0 in.

Horizontal Flue (discharge on left)

Closet

Right Side

0 in.

Left Side

0 in.

Rear

1 in.

Top

1 in.

Bottom

0 in.

Flue

0 in.

3. Is there sufficient space for servicing the furnace

and other equipment? A minimum of 24 inches

front accessibility to the furnace must be provided.

Any access door or panel must permit removal of

the largest component.

4. Are there at least 3 inches of clearance between the

furnace combustion air openings in the front panel

and any closed panel or door provided?

5. Are the ventilation and combustion air openings

large enough and will they remain unobstructed? If

outside air is used, are the openings set 12" above

the highest snow accumulation level?

6. Allow sufficient height in supply plenum above the

furnace to provide for cooling coil installation, if the

cooling coil is not installed at the time of this

furnace installation.

7. The furnace shall be installed so electrical

components are protected from water.

8. A vertical downflow furnace without a coil, must

use BAYBASE205 when installed on combustible

flooring.

9. If the furnace is installed in a garage, it must be

installed so that the burners, and the ignition

source are located not less than 18 inches above the

floor and the furnace must be located or protected

to avoid physical damage from vehicles.

10. The gas furnace must not be located where

excessive exposure to contaminated combustion

air will result in safety and performance related

problems. Avoid the following contaminants:

a. Permanent wave solutions

b. Chlorinated waxes and cleaners

c. Chlorine based swimming pool chemicals

d. Water softening chemicals

e. De-icing salts or chemicals

f.

Carbon tetrachloride

g. Halogen type refrigerants

h. Cleaning solvents (such as

perchloroethylene)

i.

Printing inks, paint removers, varnishes, etc.

j.

Hydrochloric acid, Cements and glues

k. Antistatic fabric softeners for clothes dryers

l.

Masonry acid washing materials

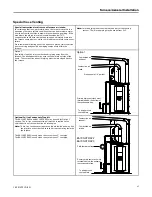

IMPORTANT: The furnace must be installed level. The

only allowable variation would be slightly to the left

and/ or forward in upflow installations or slightly

toward the front in horizontal installations. This is

necessary for proper condensate drainage.