102

18-CE03D1-1F-EN

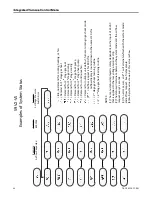

Sequence of Operation

N

No

otte

e:: The seven segment LED readout is based on

thermostat input. During a simultaneous call for

W1 and W2, the seven segment LED will read

“

Xt2

”, although the IFC will process the call for

1

st

stage heat first.

1

1

sstt

S

Stta

ag

ge

e G

Ga

ass H

He

ea

attiin

ng

g

1. R – W1 contacts close on the thermostat sending

24VAC to the W1 low voltage terminal of the IFC.

Technician should read 24VAC from W1 to B/C. The

seven segment LED will read “

Xt1

”.

2. T

Th

he

e IIF

FC

C p

pe

errffo

orrm

mss a

a sse

ellff--cch

he

ecckk rro

ou

uttiin

ne

e a

an

nd

d tth

he

en

n

cco

on

nffiirrm

mss::

a. Condensate pressure switch and Inducer limit

switch are closed by sending 24VAC out the

HLO terminal and monitoring the ILI input.

b. Flame roll-out switches (FRS) 1 & 2, main

thermal limit (TCO), and any reverse air flow

(RAF) switches are closed by sending 24VAC out

the HLO terminal and monitoring the HLI input.

N

No

otte

e:: Downflow units will have one reverse air

flow switch (RAF).

Upflow units will have two reverse air

flow switches (RAF).

c. Pressure switch 1 (PS1) and pressure switch 2

(PS2) are opened by sending 24VAC out the

HLO terminal, through the limit switches, and

monitoring the PS1 and PS2 inputs.

N

No

otte

e:: If a thermal limit is open, 24VAC will not

be present at either pressure switch.

3. After steps 2a, b, and c are confirmed, the variable

speed inducer is energized and will run at the

predetermined factory default 1

st

stage inducer

speed. As the inducer ramps up, PS1 will close.

4. When PS1 closes, the ignitor relay on the IFC will

close. The ignitor is energized and warm up is

approximately 20 seconds.

5. After the ignitor warm up, the 1

st

stage gas valve

relay is closed, energizing the 1

st

stage gas valve

solenoid to allow ignition.

6. The first burner will ignite and flame will crossover

to the remaining burners, establishing current to

the flame sensor. Flame sensing must take place

within 4 seconds.

7. Once flame sense has been achieved, a timer on the

IFC starts and after the “Blower On” delay has

completed, the indoor blower will energize and run

at the 1

st

stage gas heating speed.

•

During this time, the variable speed inducer will

start its 1

st

stage learning routine, seen as

L

LR

R1

1

on the seven segment LED display.

X

Xt

t1

1

and

L

LR

R1

1

will alternately be displayed until the learning

routine has been successfully completed. See

Learning Routine section below for specifics.

8. Once the 1

st

stage learning routine has successfully

been achieved, the seven segment LED will

alternately read:

XtI

= Gas heating, Stage 1

ARF

= Airflow

060

= 600 requested cfm (value shown x 10)

9. When the temperature raises enough to satisfy the

thermostat setting, contacts R-W1 will open.

10. The gas valve relay will open, closing the gas valve.

The inducer will continue to run the post-purge for

approximately 5 seconds to remove any

combustion byproducts from inside the furnace.

11. The indoor blower continues to run the heat off

delay to remove heat from the heat exchangers.

The blower off time is field adjustable through the

IFC menu setup option. The seven segment LED will

read “

IDL

” = Idle, no thermostat demand.

2

2

n

nd

d

S

Stta

ag

ge

e G

Ga

ass H

He

ea

attiin

ng

g

N

No

otte

e:: 2

nd

stage heating cannot operate without 1

st

stage operation.

1. R – W1 contacts close on the thermostat sending

24VAC to the W1 low voltage terminal of the IFC.

Technician should read 24VAC from W1 to B/C. The

seven segment LED will read “

Xt1

”.

2. T

Th

he

e IIF

FC

C p

pe

errffo

orrm

mss a

a sse

ellff--cch

he

ecckk rro

ou

uttiin

ne

e a

an

nd

d tth

he

en

n

cco

on

nffiirrm

mss::

a. Condensate pressure switch and Inducer limit

switch are closed by sending 24VAC out the

HLO terminal and monitoring the ILI input.

b. Flame roll-out switches (FRS) 1 & 2, main

thermal limit (TCO), and any reverse air flow

(RAF) switches are closed by sending 24VAC out

the HLO terminal and monitoring the HLI input.

N

No

otte

e:: Downflow units will have one reverse air

flow switch (RAF).

Upflow units will have two reverse air

flow switches (RAF).

c. Pressure switch 1 (PS1) and pressure switch 2

(PS2) are opened by sending 24VAC out the

HLO terminal, through the limit switches, and

monitoring the PS1 and PS2 inputs.

N

No

otte

e:: If a thermal limit is open, 24VAC will not

be present at either pressure switch.

3. After steps 2a, b, and c are confirmed, the variable

speed inducer is energized and will run at the

predetermined factory default 1

st

stage inducer

speed. As the inducer ramps up, PS1 will close.

4. When PS1 closes, the ignitor relay on the IFC will

close. The ignitor is energized and warm up is

approximately 20 seconds.