29

cleanout. UN•LIME

®

and the booklet may be obtained through

your American dealer or distributor.

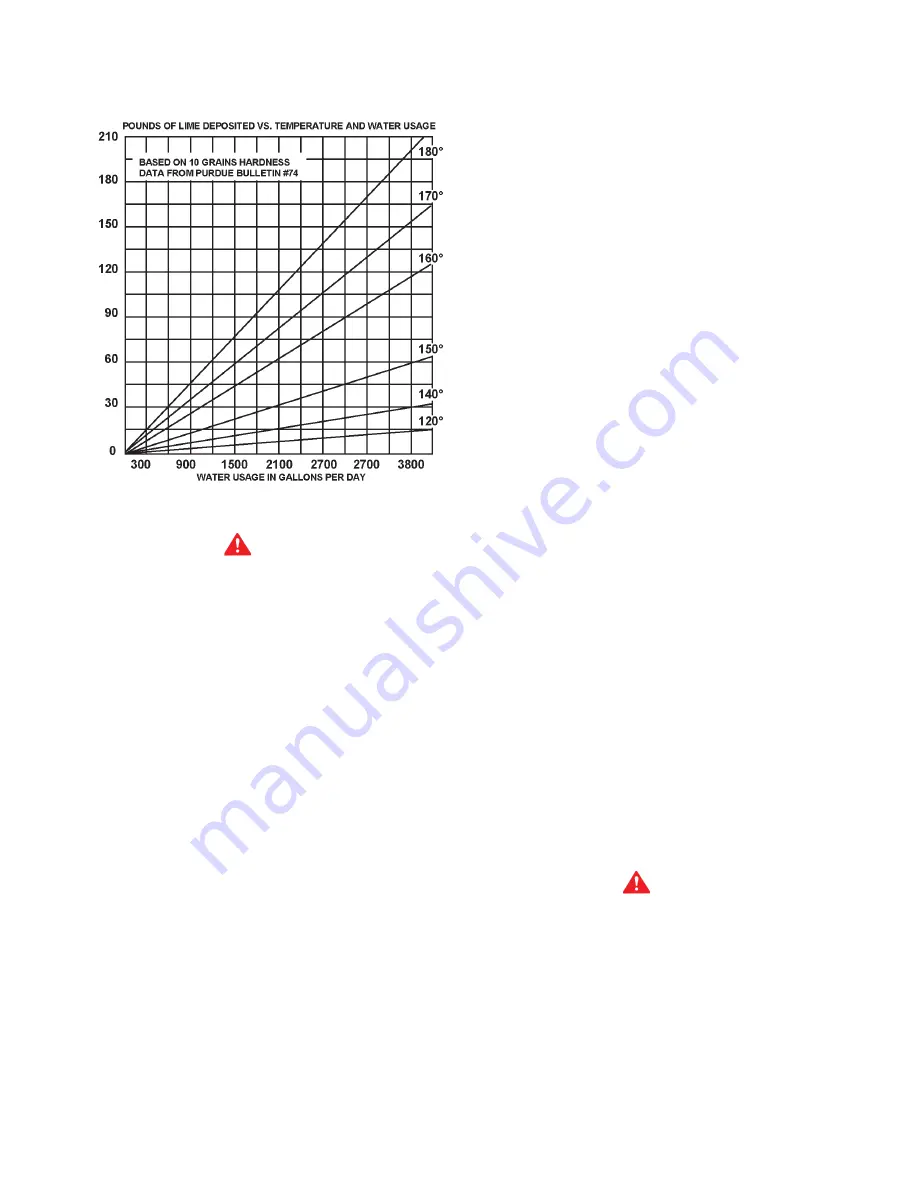

FIGURE 18

CAUTION

Observe handling instructions on label of product being used.

TANK CLEANOUT PROCEDURE

The following practices will ensure longer life and enable the unit

to operate at its designed efficiency:

1. Once a month the heater should be flushed. Open the drain

valve and allow two gallons of water to drain from the heater.

Inlet water valve should remain open to maintain pressure in

tank.

2. A cleanout opening is provided for periodic cleaning of the

tank. Gas must be shut off and heater drained before opening

cleanout.

To clean heater through cleanout opening, proceed as follows:

1. Drain heater.

2. Remove outer cover plate from lower side of heater jacket.

3. Remove six (6) hex head screws securing tank cleanout plate

and remove plate.

4. Remove lime, scale, or sediment using care not to damage the

glass lining.

5. Inspect cleanout plate gasket, if new gasket is required, replace

with American Water Heater Company part no. 99038.

6. Install cleanout plate. Be sure to draw plate up tight by

tightening screws securely.

7. Replace outer jacket cover plate.

TROUBLESHOOTING

IGNITION MODULE SYSTEM

Before calling your service agent, the following checklist should

be examined to eliminate obvious problems from those requiring

replacement or servicing.

— Check that “main manual gas shut-off valve” is fully open and

that gas service has not been interrupted.

— Check that after following the appliance OPERATING

INSTRUCTIONS, the “Top Knob” of the appliance gas valve

is in “ON” position.

— Check electrical supply to the appliance for possible blown (or

tripped) fusing or power interruption.

— Is the water temperature in tank below the thermostat

dial setting on the appliance thermostat (calling for

heat)?

— It is possible that the high limit (E.C.O.) has functioned

to shut off the appliance. See FEATURES — Water

Temperature Control for reset procedure. Contact your

serviceman if limit continues to function to shut off

appliance.

SERVICE

The installer may be able to observe and correct certain

problems which may arise when the unit is put into operation.

HOWEVER, it is recommended that only qualified servicemen,

using appropriate test equipment, be allowed to service the

heater.

As preliminary step, check wiring against diagram, check for

grounded, broken or loose wires. Check all wire ends to be sure

that they are making good contact.

ELECTRICAL SERVICING

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

REPLACEMENT PARTS

Replacement parts may be ordered through American

Water Heater Company. When ordering parts be sure

to state the quantity, part number and description of the

item(s) including the complete model and serial number

as it appears on the product. Refer to the part’s list for

more information.

Summary of Contents for ABCG3

Page 33: ...33 NOTES ...

Page 34: ...34 NOTES ...

Page 35: ...35 NOTES ...

Page 36: ...36 P O Box 1597 500 Princeton Road Johnson City TN 37605 ...