8

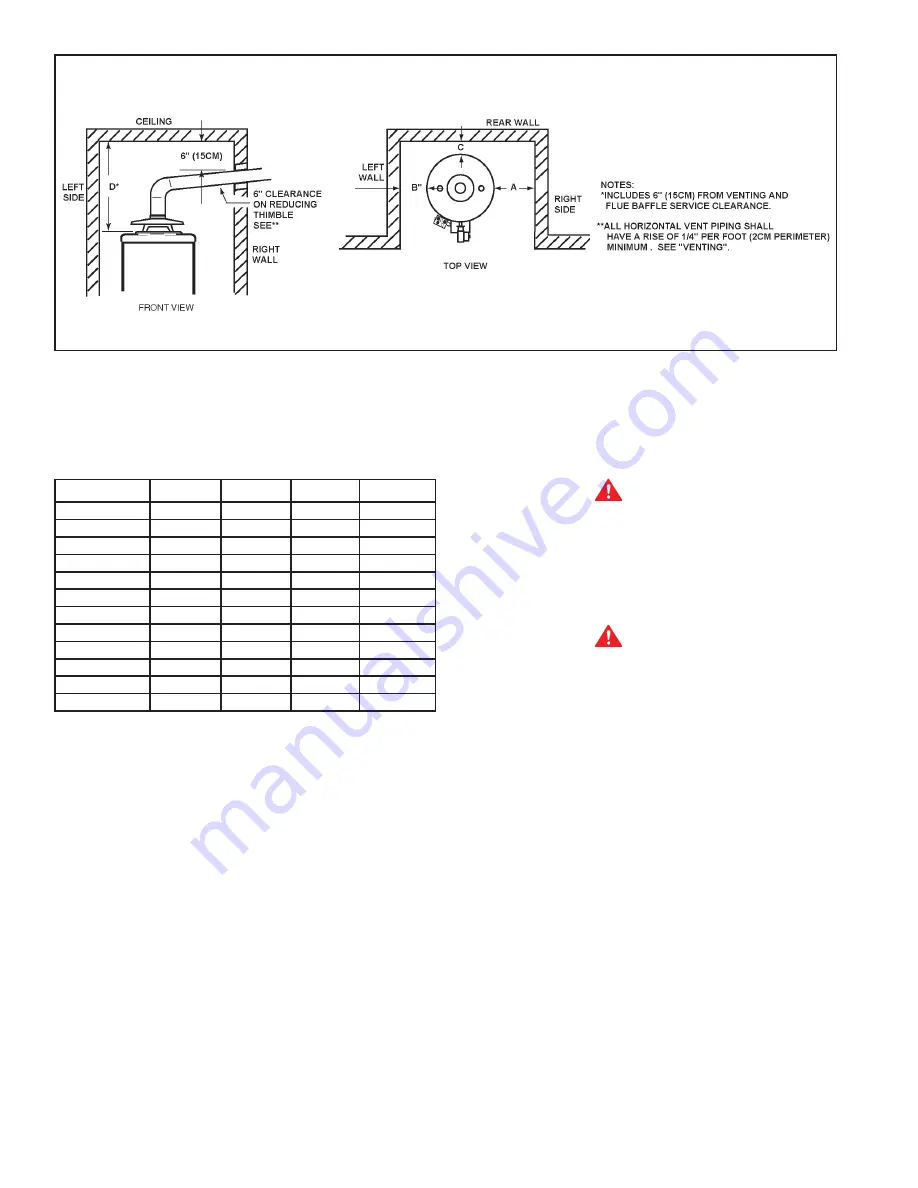

A

(RIGHT SIDE)

B

(LEFT SIDE)

C

(BACK)

D

(CEILING)

BCG370T120’s

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

BCG380T150’s

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

BCG380T180’s

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

BCG3100T199’s

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

BCG380T199’s

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

(A)BCG3100T200’s

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

(A)BCG3100T250’s

2” (5.08 cm)

2” (5.08 cm)

2” (5.08 cm)

12” (30.48 cm)

(A)BCG365T250’s

2” (5.08 cm)

2” (5.08 cm)

2” (5.08 cm)

12” (30.48 cm)

(A)BCG3100T275’s

2” (5.08 cm)

2” (5.08 cm)

2” (5.08 cm)

12” (30.48 cm)

(A)BCG365T300’s

2” (5.08 cm)

2” (5.08 cm)

2” (5.08 cm)

12” (30.48 cm)

(A)BCG385T360’s

3” (7.75 cm)

3” (7.75 cm)

3” (7.75 cm)

12” (30.48 cm)

(A)BCG3100T390’s

3” (7.75 cm)

3” (7.75 cm)

3” (7.75 cm)

12” (30.48 cm)

TABLE 2

In all installations the minimum combustible clearances from any

draft hood surface or vent piping shall be 6” (16cm). Vent piping

passing through a combustible wall or ceiling must be a continuous

run (no joints) and retain the 6” (16cm) clearance unless an

approved reducing thimble is used.

A service clearance of 24” (61cm) should be maintained from

serviceable parts, such as relief valves, flue baffles, flue damper

devices, thermostats, cleanout openings or drain valves.

HARD WATER

Where hard water conditions exist, water softening or the threshold

type of water treatment is recommended. This will protect the

dishwashers, coffee urns, water heaters, water piping and other

equipment.

See MAINTENANCE section for details of tank cleanout

procedure.

AIR REQUIREMENTS

REFER TO THE CURRENT EDITION OF THE “NATIONAL FUEL

GAS CODE” ANSI Z223.1/NFPA 54.

WARNING

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLES, VAPORS

AND LIQUIDS.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION OR

VENTILATING AIR.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR

COMBUSTION AND VENTILATION. AN INSUFFICIENT SUPPLY

OF AIR WILL CAUSE RECIRCULATION OF COMBUSTION

PRODUCTS RESULTING IN AIR CONTAMINATION THAT MAY

BE HAZARDOUS TO LIFE. SUCH A CONDITION OFTEN WILL

RESULT IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING

CARBONING OR SOOTING OF THE COMBUSTION CHAMBER,

BURNERS AND FLUE TUBES AND CREATES A RISK OF

ASPHYXIATION.

Where an exhaust fan is supplied in the same room with a

heater, sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN

INTO THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT IN SERIOUS DAMAGE

TO THE HEATER AND RISK OF FIRE OR EXPLOSION.

UNCONFINED SPACE

In buildings of conventional frame, brick, or stone construction,

unconfined spaces may provide adequate air for combustion,

ventilation and draft hood dilution.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation and draft hood dilution must be obtained from

outdoors. The installation instructions for confined spaces in

tightly constructed buildings must be followed to ensure adequate

air supply.

ILLUSTRATION OF MINIMUM COMBUSTIBLE CLEARANCES IN AN ALCOVE

FIGURE 6

Summary of Contents for ABCG3

Page 33: ...33 NOTES ...

Page 34: ...34 NOTES ...

Page 35: ...35 NOTES ...

Page 36: ...36 P O Box 1597 500 Princeton Road Johnson City TN 37605 ...