INDEX

A. TIM-615: GENERAL OVERVIEW

1) LCD Display

2) User Buttons

3) Measurement Chamber

4) Batteries

B. INSTALLATION

C. DAILY USE

D. CALIBRATION

1) Definitions

2) Reasons to Calibrate

3) Calibration Procedure

4) Display the K Factor & Restoring the

Factory K Factor

5) In-Field Calibration

6) Direct Calibration of the K Factor

E. UNIT OF MEASURE SETUP

F. METER MAINTENANCE

G. TROUBLESHOOTING GUIDE

H. PARTS BREAKDOWN AND SPECIFICATIONS

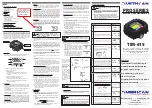

A. AMERICAN LUBRICATION TIM-615: GENERAL OVERVIEW

TIM-615 is an electronic digital oval-gear meter, designed for precise

measuring of oil and other liquids that are compatible with the

materials found in the meter. The TIM-615 features a non-volatile

memory for storing calibration and dispensing data in the event of

a complete power loss. The meter is unique in that the electronic

section is completely isolated from the fluid section. This means that

the electronics can be easily field replaced while the meter is still

installed in-line using a replacement electronics “head”.

1) LCD Display

The “LCD” of the TIM-615 features two numerical registers and

various symbols that are displayed only when required.

Batch register indicates volume dispensed

Battery charge Indicator

Calibration Mode

Total register; display can show (2) different totals,

one which is resettable and one that is non-

resettable.

Total multiplication factor ( x10 or x100 )

Total type (TOTAL / RESET TOTAL)

Total unit of measurement (Gal=Gallons, L=Liters)

Batch unit of measurement (Qts=Quarts, Pts=Pints,

L=Liters, Gal=Gallons

2) User Buttons

The TIM-615 meter features two buttons (RESET and CAL )

which individually perform two main functions and when pressed

at the same time together perform secondary functions. The

functions are:

For the RESET button, resetting the batch register and the

resettable totalizer.

For the CAL button, entering meter calibration mode.

Pressing RESET and CAL together enters the configuration

mode where the desired unit of measurement can be set.

3) Fluid Chamber

The measurement chamber is located in the lower part of the

meter. It features a 1/2” NPT(F) inlet and outlet. The cover on the

bottom provides access to the chamber for contaminate cleaning.

Inside the chamber are two oval gears that generate electrical

pulses which are counted by the microprocessor. By applying a

calibration factor, the microprocessor translates the pulses into

units of measurement, displayed on the batch and total registers

of the LCD. All TIM-615’s are factory set with a calibration factor

(FACTORY K FACTOR) equal to 1,000.

4

5 6

8

7

1

2

3

2. Reasons to Calibrate

The TIM-615 is supplied with a factory calibration that ensures

precise measuring in most operating conditions. Meter accuracy

might be compromised when dispensing fluids like low-viscosity

automatic transmission fluid or high-viscosity gear oils. The

meters’ accuracy also might be compromised when operating at

flow rates that are close to the minimum or maximum.

When the meter’s accuracy is less than ideal, user calibration can

be performed to better suit the actual conditions in which the TIM-

615 is required to operate.

3. Calibration Procedure

Two procedures are available for changing the Calibration

Factor:

Dispensing Calibration, performed by means of a dispensing

operation.

Direct Calibration, performed by directly changing the

calibration factor inside the meter.

The calibration phases can be entered (by keeping the CAL button

pressed for a few seconds) to:

Display the current user calibration factor

Return to factory calibration (Factory K Factor) after a previous

calibration by the user

Change the calibration factor using one of the two previously

indicated procedures.

During calibration, the batch and total dispensed quantities

indicated

on the display screen take on different meanings

according to the calibration procedure phase.

In calibration mode, the TIM-615 cannot be used for normal

dispensing operations. During the calibration process, the totals

are not increased.

4. Displaying the K Factor & Restoring the Factory K Factor

By pressing the CAL button while the meter is in standby mode,

one of two display pages will appear showing the current

calibration factor.

The following display page will appear if

calibration has been performed or the meter

has been restored to factory calibration.

The word “FACT” (abbreviation for “factory”)

indicates that the factory calibration factor is

being used.

This display page will appear if a calibration

has been made by the user. It shows the

current used calibration factor (in the example

0.998) and the word “USER” (indicating that

the user calibration factor is being used)

The flow chart shows

the switch-over logic

from one display page

to another

In this condition, the

Reset button permits

switching from the

User factor to the

Factory factor.

To confirm the choice

of the calibration

factor, quickly press

the CAL button while

“USER” or “FACT”

are displayed.

After the restart cycle,

the TIM-615 uses

the calibration factor

that had just been

confirmed

5. In-Field Calibration

This procedure requires the fluid to be dispensed into a certified

graduated container. For best accuracy, perform this procedure when

the meter is installed in the system it is going to be used on.

5. In-Field Calibration (continued)

ACTION

DISPLAY

1

Make sure the meter is in standby mode

.

If you are unsure, press the REST button and wait 10

seconds.

2

Hold down the CAL button until the display reads

“CAL”.

The TIM-615 enters calibration mode, shows <<CAL>> and

displays the calibration factor in use. The words “FACT” and

“USER” indicate which of the two factors (factory or user)

is currently in use.

3

Hold down the RESET button until the display reads

“FIELD”.

The TIM-615 shows “CAL” and the batch register set to

zero. The TIM-615 is ready to perform in-field dispensing

calibration.

4

Dispensing into a calibrated container.

Without pressing any buttons, start dispensing

into the graduated container.

Dispensing can be stopped and started again

at will. Continue dispensing until the level of

the fluid in the sample container has reached

the graduated area.

Make sure dispensing is correctly finished before performing

the next step.

5

Press the RESET button, and quickly release.

This tells the meter that the dispensing is finished. To

finish calibrating the meter, the value on the meter’s batch

display (example 9.800) must be adjusted to equal the

actual amount in the calibrated container. In the bottom left

part of the display an arrow appears (pointing upwards or

downwards), that shows the direction (increase or decrease)

that the value on the batch display will be changed when

performing step 7.

6

Changing the Arrows direction in the display

Quickly pressing the RESET button changes the arrows

direction in the display. This operation can be repeated to

alternate the direction of the arrow.

7

Adjusting the Batch Display Value (

The indicated value

changes in the direction indicated by the arrow)

1) The amount on the display changes one unit each

time the CAL button is pressed quickly.

2) The amount on the display changes continuously

if the CAL button is kept pressed. The speed

of change increases the longer the button is

held.

If you accidentally program the wrong value, repeat the

operation starting from step number 6

8

Saving the New Calibration Factor

Before performing this operation, double-check to make

sure the display value on the meter is the same value that is

in the calibrated container.

Press the RESET button for at least one second. The TIM-

615 calculates the new USER K FACTOR. This calculation

could require a few seconds to compute. At the end of the

calculation, the new USER K FACTOR is shown for a few

seconds.

9

Finishing

The meter will re-start and enter into the standby mode. The

meter is now programmed with the new calibration factor

and is ready to use.

Note: The calibrated USER K FACTOR is now the factor

used in the TIM-615. This will be the factor the meter will

use even after battery failure and battery replacement.

CAL BUTTON

RESET

BUTTON

LCD DISPLAY

a) For a few seconds after the RESET button is pressed.

b) During the entire dispensing stage and for five seconds after

dispensing. Once this short time has expired the TIM-615

switches to standby mode and the lower register switches

back to the non-resettable total (TOTAL).

NOTE: 6 digits are available for TOTALS, plus two

icons x 10 / x100. The increment sequence follows: 0.0

→ 99999.9 → 999999 → 100000 x 10 → 999999 x 10 →

100000 x 100 → 999999 x 100

!

!

NOTE: The TIM-615 features a non-volatile memory for

storing calibration and dispensing data. There is no

need to re-calibrate the meter in the event of power loss.

NOTE: When the Factory Factor is chosen, the old user

factor is deleted from the memory

!

1) Completely eliminate all of the air from the system before calibrat-

ing.

2) Use a certified graduated container with a minimum capacity of

5 Qts. Do not use metal or plastic oil containers typically found in

automotive shops. These are typically not accurate enough.

!

NOTE: Important steps for accurate meter calibration:

!

NOTE: Important steps for accurate meter calibration:

(continued)

3) Try to keep the flow rate constant when filling the container. Do

not trickle the flow to reach the desired level (the correct method

during the final stage is to make short top-offs at the normal

operating flow rate).

4) When oil is dispensed into a container, air gets trapped

inside the oil, making the level in the container appear

higher than it really is. After dispensing, wait a few minutes

to make sure all air bubbles are eliminated from the fluid

inside the calibration container.

4) Batteries

The TIM-615 is powered by two standard AAA 1.5V Alkaline

batteries. The batteries can be found under the face of the meter

by removing the four top screws and the protective cover.

B. INSTALLATION

The TIM-615 features two ½” NPT(F) ports. It has been designed to

be installed in any position, in a fixed in-line installation or as part

of a control handle. The meter does not have specific direction of

flow and either port can be used as inlet or an outlet. Make sure

the threaded connections do not interfere with the inside of the

measurement chamber. This can cause the gears to be damaged

and/or seize. A filter with adequate filtering capacity should always

be placed at the inlet of the meter or somewhere in the product

line onto which the TIM-615 is mounted. If solid particles enter the

measurement chamber, the gears could be damaged and/or seize.

C. DAILY USE

Below are the two normal display modes. One display page shows

the batch and resettable total registers (temporary display mode).

The other page shows the batch and non-resettable total register

(standby display mode). Changeover between these two pages

is automatic and tied to phases and times that are factory set and

cannot be changed by the user.

*The batch register is in the top of the display and indicates the

quantity dispensed since the last time the RESET button was

pressed

*The resettable total register (Reset

TOTAL), positioned in the

lower part of the display, indicates the quantity dispensed since

the last time the resettable total was reset. The resettable total

cannot be reset until the batch register has been reset. The unit of

measurement of the two total registers can be the same as the batch

register or a different unit of measure depending on the factory or

user programming choice.

*The non-resettable total register (TOTAL) can never be reset by the

user. It continues to rise for the entire operating life of the TIM-615.

*The register of the two totals (Reset TOTAL and TOTAL) share the

same line of the display. The TIM-615 is programmed to show each

of these totals at different times.

*The non-ressettable (TOTAL) page is shown in standby screen

mode

*The resettable total (Reset TOTAL) page is shown in the temporary

screen mode:

1) Resetting the Batch Register

The batch register can be reset by pressing the RESET button

only when the meter is in standby mode. Press the RESET button

to reset the batch register. After pressing the RESET button, the

LCD screen will display all the characters on the screen, and

then the screen will momentarily go blank. The screen will then

display the resettable total for 5 seconds, after which the display

will return to the standby mode screen.

2) Resetting the Resettable Total (Reset TOTAL)

Wait for the display to enter standby mode

Press the RESET button quickly. This will reset the batch

register.

After pressing the RESET button, the LCD screen will display

all the characters on the screen, and then the screen will

momentarily go blank. The screen will then display the

resettable total for 5 seconds. Hold down the Reset button for

at least one second.

The LCD screen will again display all the characters on the

screen, and then the screen will momentarily go blank. The

screen will then display the resettable total (which now should

read 0.0) for 5 seconds

D. CALIBRATION

1.

Definitions

Calibration factor or “K Factor” - this is the multiplication factor

applied by the system to the electrical pulses received, to

transform these into measured fluid units.

Factory K Factor: Factory-set default factor. It is equal to

1,000.

The Factory K Factor is based on the following operating

conditions:

User K Factor:

Customized calibration factor, meaning the K

Factor obtained from calibrating the meter.

Temporary Display Mode

Standby Display Mode

Batch Display

Actual Value

Indicated Value

Real Value

1)

2)

3)

4)

5)

6)

7)

8)

a)

b)

c)

Fluid

10W30 motor oil

Temperature:

68° F.

Flow rate:

1.3 - 6.6 gallons/min.

a)

b)

c)

d)

a)

b)

c)

a)

b)

a)

b)

c)

PRO SERIES

DIGITAL OVAL GEAR METER

TIM-615

This meter is built exclusively for American

Lubrication Equipment Corporation incorporating

numerous design ideas provided by their design team.

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

PRO SERIES METER

Baltimore, Md. Los Angeles, Ca.

410

-252-9300

americanlube.com

Features

Fluid Isolated from the Electronics

Field-Replaceable Electronic Head

Reliable Oval Gear Design

New AAA Ba

t

tery Lasts Longer

6 Bolt Construction

Programmable to Pts, Qts, Lts & Gals

Molded-in Shock Guard

Bulletin M0169 EN rev.1

Bulletin M0169 EN rev.1

The batch register (top

row) can be reset; the total

register (bottom row)

cannot be reset (even if

you take the batteries

out).