D. CALIBRATION (continued)

6. Direct Calibration of the K Factor

This procedure is useful if the meter is over-dispensing or under-

dispensing fluid by a known percentage. Using this method, the

correction of the USER K FACTOR must be calculated by the

operator using the following formula:

New Cal. Factor = Old Cal Factor *

( )

100 - E%

100

Example:

Error percentage found

(

E%)

- 0.3 %

CURRENT calibration factor

1.000

New USER K FACTOR

1.000 * [(100 – ( - 0.3))/100]

= 1.000 * [(100 + 0.9)/100]

= 1.003

If the TIM-615 is under-dispensing (negative error), the new

calibration factor must be higher than the old one as shown in the

example. The opposite applies if the TIM-615 is over-dispensing

(positive error).

ACTION

DISPLAY

CONFIGURATION

1

Make sure the meter is in standby mode

.

If you are unsure, press the REST button and wait 10

seconds.

2

Hold down the CAL button until the display reads

“CAL”.

The TIM-615 enters calibration mode, shows <<CAL>>

and displays the calibration factor in use. The words

“FACT” and “USER” indicate which of the two factors

(factory or user) is currently in use.

3

Hold down the RESET button until the display reads

“FIELD”.

The TIM-615 shows “CAL” and the batch register set to

zero. The TIM-615 is ready to perform in-field dispensing

calibration.

4

Hold down the RESET button until the display reads

“DIRECT”.

In the bottom left part of the display an arrow appears

(pointing upwards or downwards), that shows the direction

(increase or decrease) that the value on the batch display

will be changed when performing step 6.

5

Changing the Arrows direction in the display

Quickly pressing the RESET button changes the arrows

direction in the display. This operation can be repeated to

alternate the direction of the arrow.

6

Adjusting the Batch Display Value (

The batch display

value changes in the direction indicated by the arrow)

1) The amount on the display changes one unit each

time the CAL button is pressed quickly.

2) The amount on the display changes continuously

if the CAL button is kept pressed. The speed

of change increases the longer the button is

held.

If you accidentally program the wrong value, repeat the

operation starting from step number 5.

7

Saving the New Calibration Factor

Before performing this operation, double-check to make

sure the display value on the meter is equal to the value

you obtained using the calibration formula.

Press the RESET button for at least one second. The TIM-

615 calculates the new USER K FACTOR. This calculation

could require a few seconds to compute.

At the end of the calculation, the new USER K FACTOR is

shown for a few seconds.

8

Finishing

The meter will re-start and enter into the standby mode.

The meter is now programmed with the new calibration

factor and is ready to use.

Note: The calibrated USER K FACTOR is now the

factor used in the TIM-615. This will be the factor the

meter will use even after battery failure and battery

replacement.

E. UNIT OF MEASURE SETUP

The user can select the batch measurement unit. The choices are:

Quarts (

Qts

), Pints (

Pts

), Liters (

Lit

), and Gallons (

Gal

). The total

register unit of measurement is automatically determined based on

what is chosen for the batch measurement unit (see chart below).

Combination no.

Unit of Measurement

Partial Register

Unit of Measurement

Totals Register

1

Liters (L)

Liters (L)

2

Gallons (Gal)

Gallons (Gal)

3

Quarts (Qts)

Gallons (Gal)

4

Pints (Pts)

Gallons (Gal)

E. UNIT OF MEASURE SETUP (continued)

To choose between the 4 available combinations:

Wait for the TIM-615 to go to

Standby.

Press and hold the CAL and RESET

buttons together. Keep these pressed

until the word “UNIT” appears on the

screen. You will also see the current

units of measure (in this example Qts

& Gal).

Each quick press of the RESET

button changes the units of measure.

The chart below shows the order of

scrolling.

Press the CAL key for a few seconds

and the new unit of measurement

will be stored. The meter will re-start

and enter into the standby mode.

The meter is now programmed with

the new unit(s) of measure and is

ready to use.

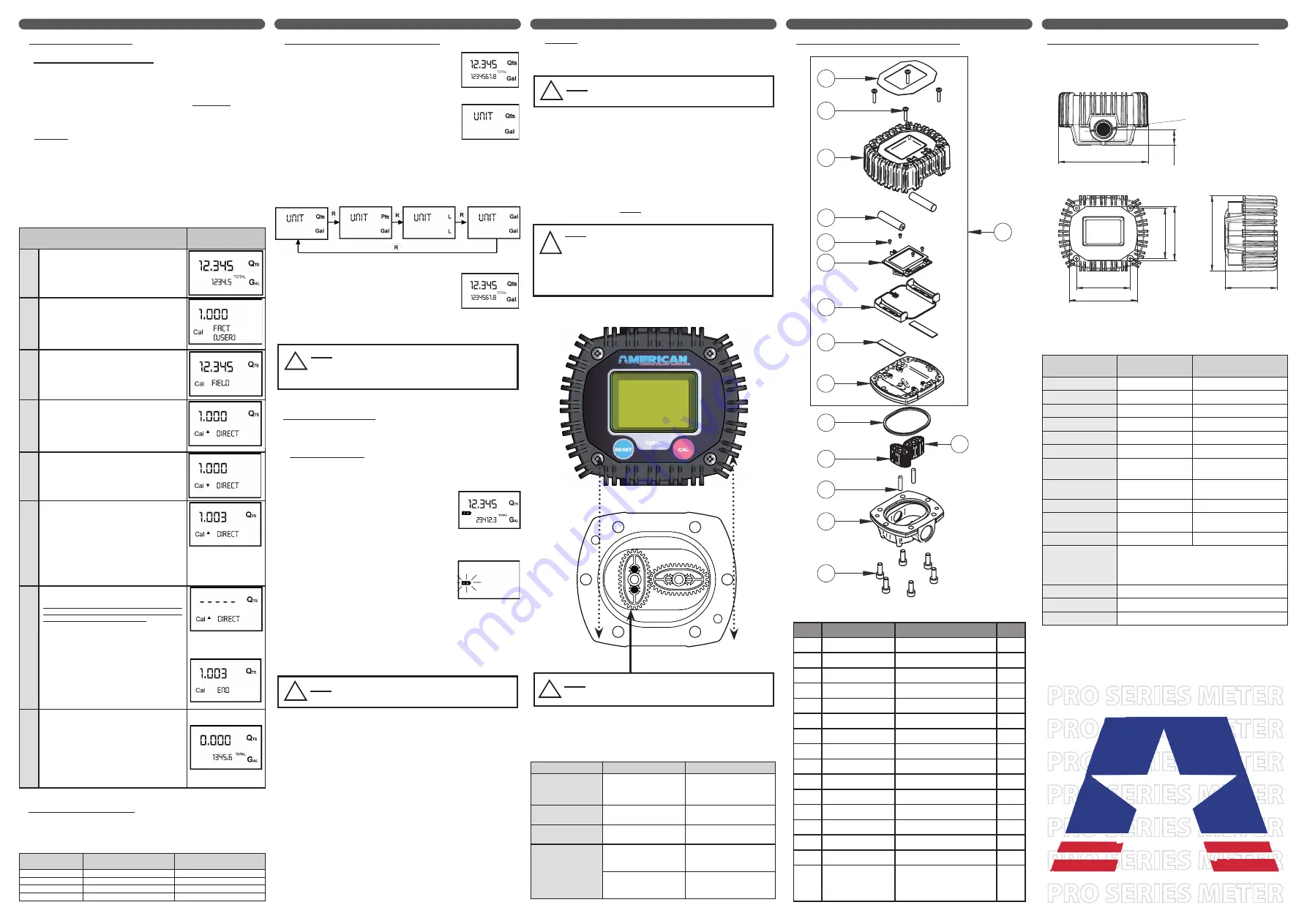

F. METER MAINTENANCE

The TIM-615 was designed to require minimal maintenance. The

only maintenance required is battery replacement and cleaning the

measuring chamber.

1) Battery Replacement

The TIM-615 is supplied with two SIZE AAA, 1.5 Volt Alkaline

batteries. The meter features two low-battery alarm warnings:

When the battery charge falls

below the first level, the fixed battery

symbol appears on the LCD. In

this condition, the meter continues

to operate correctly, but the fixed

battery icon warns the user that it is

time to change the batteries.

If you continue to use the meter

without changing the batteries

the second battery alarm level will

eventually be reached, preventing

meter operation. In this condition

the battery icon will flash and will

be the only item visible on the LCD.

You must change the batteries once

the meter has reached this mode.

All dispensing data from this point

forward will not be displayed or

stored in the meter.

To change the batteries, refer to the spare parts list

in the next column while completing the following

steps:

Press reset to update all the totals.

Remove the 4 screws on the cover (item 5).

Remove the cover (item 8).

Replace the two dead batteries (item 9).

Put the cover on and re-tighten the 4 cover screws,

making sure that it has been positioned correctly.

The meter will switch on automatically and enter

into the standby mode. It is now ready to resume

normal operation.

After changing the batteries, the meter will display

the same reset total, the same non-ressettable

total and the same batch total as it did before the

batteries were changed. The meter will also use the

same calibration factor as it did before the power

outage/battery replacement.

2) Cleaning

The measuring chamber of the TIM-615 can be cleaned without

removing the unit from the dispensing nozzle or the line on which

it is installed.

To clean debris from the measuring chamber, refer to the spare

parts list on the right while completing the following steps:

Loosen the six retention screws (item 7) on the

body (item 1).

Remove the cover (item 2) and the seal (item 10)

Remove the two oval gears (item 13).

Clean where necessary. For this operation, use a

brush or pointed object such as a small screwdriver.

Be careful not to damage the body or the gears.

To reassemble the unit, carry out these steps in

the reverse order. Please pay close attention to the

note below before re-assembling the meter!

G. TROUBLESHOOTING GUIDE

Problem

Possible cause

Remedial Action

Dull LCD

Low Battery

Replace the batteries

(see section F.)

Inaccurate

Dispensing

Wrong K FACTOR

Re-calibrate

(see section D.)

Reduced or Zero

Flow Rate

Gears blocked

Clean the measurement

chamber (see section F.)

The meter does

not count, but

the flow rate is

correct

Incorrect installation of

gears after cleaning

Repeat the reassembly

procedure

(see section F.)

Possible circuit board

problem

Contact your local

American Lubrication

Equipment dealer

H. PARTS BREAKDOWN & SPECIFICATIONS

Item

Part Number

Description

Qty

1

TIM-615-1

Fluid Chamber Body

1

2

TIM-615-2

Isolation Plate

1

3

TIM-615-3

Battery Support Tray

1

4

TIM-615-4

Circuit Board

1

5

TIM-615-5

Cover Screw

4

6

TIM-615-6

Circuit Board Screw

4

7

TIM-615-7

Fluid Body Screw

6

8

TIM-615-8

Protective Cover

1

9

TIM-615-9

AAA Battery

2

10

TIM-615-10

Gasket

1

11

TIM-615-11

Cover label

1

12

TIM-615-12

Adhesive Strip

2

13

TIM-615-13

Magnetic Gear

1

14

TIM-615-14

Non-Magnetic Gear

1

15

TIM-615-15

Gear Post

2

16

TIM-615-HEAD

Replacement Meter

Head includes items 2,

3, 4, 5, 6, 8 , 9, 11 & 12

1

H. PARTS BREAKDOWN & SPECIFICATIONS (continued)

Measurement

system

Oval Gear

Resolution

(nominal)

0.005 (Quarts/Pulse)

Flow Rate

(Range)

1-26 (Quarts/Minute)

Operating pressure

(Max)

1000 (PSI)

Bursting pressure

(Min)

2000 (PSI)

Storage temperature

(Range)

-5 to 158 (°F)

Storage humidity

(Max)

95 (% RH)

Operating

temperature

(Max)

140 (°F)

Flow resistance

(at 16 quarts/min with

SAE10W motor oil at 68°F)

19 (PSI)

Viscosity

(Range)

5÷5000 (mPas)

Precision

(1 and 26 quarts/min)

±1 of value indicated after

calibration (%)

Repeatability

(Typical)

±0.3 (%)

Screen

Liquid crystals LCD

Featuring:

-

5-figure partial

-

6-figure Reset Total plus x10 / x100

-

6-figure non reset Total plus x10 / x100

Power supply

(2) 1.5 V alkaline batteries size AAA

Battery life

14,000 - 100,000 hours

Weight

.83 lbs. (including batteries)

NOTE: The Reset Total and Total will be automatically

converted to the new unit of measurement. No

new calibration is required when changing the

unit of measurement.

!

b)

a)

NOTE:

Refer to your local regulations before disposing the old

batteries.

!

1)

2)

3)

4)

c)

NOTE: Always make sure the liquid has been drained

from the meter before cleaning

.

!

NOTE: Only one of the two gears has magnets.These

gears must be inserted into the body of the meter, and

placed perpendicular to each other. To position the gears

correctly, refer to the diagram below, making sure that

the position of the gear with respect to the magnets is

observed.

If the gears are not installed correctly, the me-

ter will not work. Check that the gears are rotating freely

before closing the cover.

!

1)

2)

3)

4)

5)

6)

1)

2)

3)

4)

5)

4-1/4”

2.46”

3/

4”

2.

38

”

2.54”

1/2" NPT

3.21”

2.

55

”

3.

57

”

11

5

8

9

6

4

3

12

2

10

13

15

1

7

14

16

d)

!

NOTE:

The gear with the magnet (TIM-615-13) must be pla-

ced so that it is on the left side of the meter when assmbled