8

STEP 2:

GENERAL NOTES

This is not a passenger elevator

This lifting device is intended for vertical transport of nonliving cargo only

Do not sell, install or use for any other intended uses

Train the user for a safe use and explain to user what is the intended use of the

dumbwaiter.

Refer to approved project drawing for actual dimension and location of components.

This manual is a reference to the product series, some options might differ from your

configuration, not all instructions are susceptible to be applicable to your installation.

Load capacity is 300 lbs

Nominal speed is 24 Feet by minute

Call and send landing operating devices

Dumbwaiter provided with elevator door interlock for enhanced safety.

Press call station to unlock door while cab is at landing

Pro Serve dumbwaiter is designer in accordance with ASME A17.1 and CSA B44 (

section 7 )

Equipped with PLC controler, protection in case of failure, safety brake , slack chain

switch, door interlock, electrical disconnect.

Car guide rails are Aluminium for made

Car is 100% made of Stainless Steel

Dumbwaiter provided with a DC battery disconnect equipped with a auxiliary contact

to shut off 120V to the charger, only a outlet is required for all jurisdiction.

Consider closing the front part of the shaft once dumbwaiter is fully installed

The supporting wall shall be strongly reinforced with 2x ¾’’ plywood over doubled

2X4 stud. Alternate construction may be used if approved by the building engineer

A hatch shall be present at the lower landing to access controller, disconnect and drive

machine. The hatch shall have a separation between runway and machine space

otherwise the hatch shall be locked or screwed in place.

STEP 3:

Quick Start

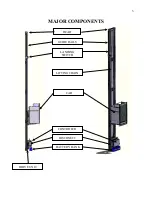

Assemble first section of rail structure outside of shaft.

Install first section of rail in the runway

Install sling on the first set of rail

Place the next assembled section of rails one over the other into the shaft up to the

last.

Route chain through idler sprocket and attach to car to lifting point, ( brake )

Verify safeties are working properly by lifting sling, allowing chain to go slack, and

confirm the brake are engaged.

Adjust as necessary for smooth operation, brake test at 125% load is required before

commissioning

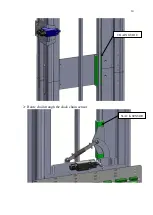

Install floor switches and final limit switch.

Mount floor switches on the LH side of the rail structure.

Run carriage to each floor level and adjust switch