7

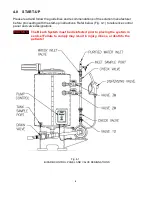

4.2 MIXING BICARB

1. Verify that the MIX OFF/ON switch is turned “OFF” and the plug of the power cord is in a

120 V, 20 AMP, and dedicated, single-phase receptacle.

2. Verify that the mix tank is empty and clean by visual inspection, and by performing a

residual disinfectant test before filling with RO water.

3. Ensure that all valves on the Bicarb System are closed.

4. Determine the batch size that is required. (Check for the Bicarb manufacturer’s

recommendation on the amount of water to use. For best results fill the mix tank to a level

3 gallons less than what is needed before adding in the powder. After the bicarbonate

powder mixes, manually add the remaining water to the proper level.)

5. Open the RO water supply and INLET WATER valves to fill the mix tank.

6. Open valve “3M” and manually fill tank to desired level.

7. Once Mix tank is filled to the desired level, close valve “3M” and RO water supply valve.

8. Open valve “2M” to send water to the mix nozzle (eductor).

9. Turn the MIX OFF/ON switch to “ON” and open the tank lid.

10.

Slowly

add the dry powder to the mixing water and close the tank lid.

11. After the mix time is complete (follow manufacture’s recommendation for mix time), turn

MIX OFF/ON switch to “OFF”, remove the lid and inspect the contents of the mix tank to

insure that all of the powder has dissolved. If not, turn MIX OFF/ON switch to “ON” and

continue mixing.

12. Use the TANK SAMPLE PORT to perform the recommended test procedures for the

solution (to check the ratio). Log the test results in your journal.

13. Allow the pump to continue mixing the solution in the tank while opening the “1D” valve.

Then use the dispensing valve to fill bottles.