24

98-0155 Rev. C

14. With the RO Operating, adjust the valve on the

Reject

flowmeter until the flow rate is

equal to the product flow rate of the RO. This will be 50% recovery. Operating the RO at

higher recovery percentage may reduce the life span of the RO membranes. Recovery is

calculated via the following equation:

(

)

(

)

100% =

15. With the RO Operating, adjust the valve on the

Recirculation

flow meter until the

recirculation flow rate is approximately 1/3

rd

of the reject flow rate.

16. Starting the RO the first time, the user can verify that the RO is operating correctly by

checking the flow meters, the controller and the inlet and outlet pressure gauges. The flow

meters will show movement on the flow bobbers in the flow meters. The flow meters

should be reading 50% product / 50% reject and 33.3% recirc. The controller will show on

the screen operating parameters, such as quality of water, Temp of water. The incoming

and outlet gauges will show pressure reading on the gauge. There will be a differential of

pressure between the two gauges.

17. When operating an MROZ with a direct feed loop, the feed water pressure should be

adjusted to approximately 25-30 PSI on the regulator found on the product recovery kit.

Setting the pressure above this may result in reduced RO permeate flow in the direct feed

loop.

WARNING: The Clean in Place Switch, located inside the cabinet on the back of the

controller, must be in the OFF position during normal operation. If the

Clean in Place Switch is left in the ON position during normal operation, all

MROZ fail-safe modes will be disabled, and damage to the MROZ or injury

to the patient may occur.

18.

Minimize the opportunities for bacterial growth between uses!

Whenever the MROZ is not used for a period of several hours, and connected to a

Direct Feed Loop, the “Membrane Flush Feature” of the MROZ should be programmed

to be active when in the STANDBY mode (See section 5 for activating this feature).

Whenever the MROZ is not used for a period of several hours, and connected to a

Storage Tank of a Central System, the “Membrane Flush Feature” of the MROZ should

be programmed to be active when in the OPERATE mode (See section 5 for activating

this feature). This feature will flush the MROZ when the Storage Tank is full and the

water level is maintained at the Tank Full High float switch by diverting the Product

Water to drain.

Before determining a bacteria count, the MROZ should be PLACED in FLUSH for 5

minutes (fully opened reject flow control knob), and then placed in OPERATE for 5 –

10 additional minutes after a period of non-use, but before taking a sample of the

PRODUCT WATER. Bacteria are known to increase in population when water is not

moving.

Summary of Contents for MRO3Z

Page 2: ...98 0155 Rev C ...

Page 5: ...98 0155 Rev C ...

Page 13: ...8 98 0155 Rev C MRO7Z and MRO8Z CONFIGURATION SHOWN BELOW Figure 3 2 ...

Page 15: ...10 98 0155 Rev C 3 2 INTERNAL CABINET TOP AND SIDE VIEW Figure 3 3 ...

Page 16: ...11 98 0155 Rev C 3 3 INTERNAL CABINET TOP AND SIDE VIEW CONT Figure 3 4 ...

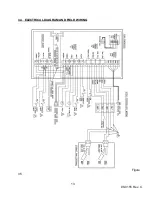

Page 18: ...13 98 0155 Rev C 3 4 ELECTRICAL DIAGRAM AND FIELD WIRING Figure 3 5 ...

Page 19: ...14 98 0155 Rev C Fig Figure 3 6 ...

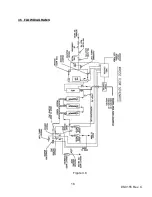

Page 20: ...15 98 0155 Rev C Figure 3 7 ...

Page 21: ...16 98 0155 Rev C 3 5 FLOW DIAGRAMS Figure 3 8 ...

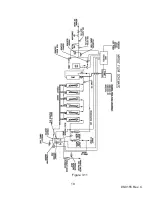

Page 22: ...17 98 0155 Rev C Figure 3 9 ...

Page 23: ...18 98 0155 Rev C Figure 3 10 ...

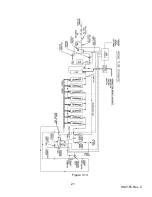

Page 24: ...19 98 0155 Rev C Figure 3 11 ...

Page 25: ...20 98 0155 Rev C Figure 3 12 ...

Page 26: ...21 98 0155 Rev C Figure 3 13 ...

Page 46: ...41 98 0155 Rev C FIGURE 6 3 ...